- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ZDQX-18MOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

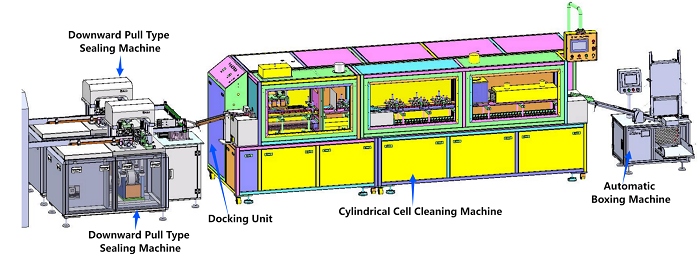

5 daysHigh-Speed 18650 Cylindrical Cell Sealing and Cleaning Machine

l Application: Fully automated sealing and cleaning process for cylindrical lithium-ion batteries after electrolyte filling.

l Integration: Supports downstream connection to boxing machines, coding machines, or sleeving machines.

l Automation: No manual intervention from sealing to cleaning.

l Capacity: >100 PCS/min

l Operation Time: Continuous 8 hours/day

l Personnel Required: 1 operator (for boxing/unloading)

l Power Supply: 380V

l Suitable Battery Type: 18650 steel shell

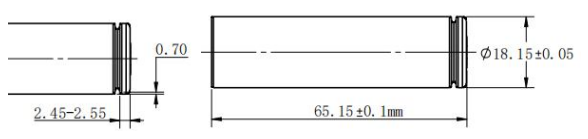

Sealing Process Dimensions

|

Item |

Dimension |

Tolerance |

Item |

Dimension |

Tolerance |

|

Cathode moisture content PPM |

≤200 |

— |

Cathode moisture content PPM |

≤350 |

— |

|

Electrolyte injection amount (g) ★ |

5.75 |

— |

Total sealing height (mm) |

65.15 |

— |

|

Sealing end height (mm) |

2.5 |

±0.2 |

Riveted sealing head outer diameter (mm) |

18.35 |

— |

|

Sealing outer diameter (mm) |

18.35 |

±0.05 |

Holding time (min) |

1 |

Airtightness |

|

Holding pressure (MPa) |

1 |

— |

Cap burst pressure (MPa) |

1.9–2.5 |

Airtightness |

|

Cap separation pressure (MPa) |

0.9–1.4 |

— |

Battery weight (g) |

43–44.5 |

— |

Notes:

Airtightness testing is mandatory — Take 3 sealed shell spaces, pressurize them on the testing machine, maintain a pressure of ≥1 MPa for 1 minute; qualification is determined by no gas leakage from the four sealing walls. For each shift, randomly select one cell for disassembly inspection to confirm that the cover plate deformation is ≤0.3 mm.

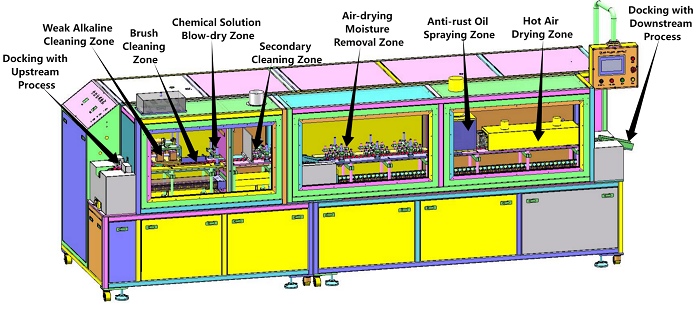

|

Process Stage |

Specification |

|

Tank 1 / 65 L |

40°C, 90% deionized water + 1100±50 g sodium nitrite, pH 9–11 |

|

Tank 2 / 65 L |

Same as above |

|

Tank 3 / 65 L |

Same as above – continuous operation for 4 hours, water must be replaced and cleaned; during cleaning, Tanks 2 & 4 remain operational without stopping the line |

|

Tank 4 / 65 L |

Same as above |

|

Oil Spraying |

14 L tank, 0.8 mm nozzle, full-body anti-rust coating |

|

Hot Air Drying |

Temperature: 70°C, surface clean, no water, no electrolyte residue, uniform oil film; conveyor chain cleaned twice per shift |

|

Boxing |

Alcohol wiping → Anti-rust oil application on both ends → Cathode-down placement → Plastic film wrapping; film sleeving & coding within 24 hours after cleaning |

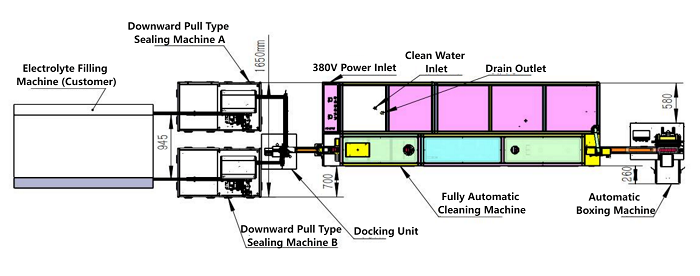

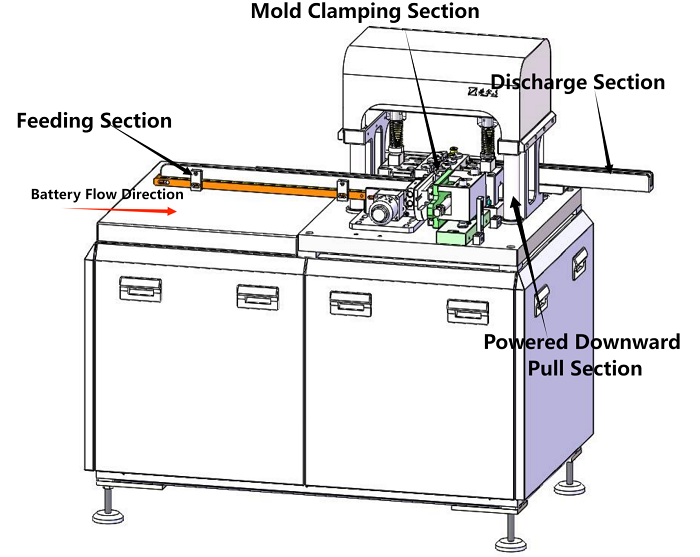

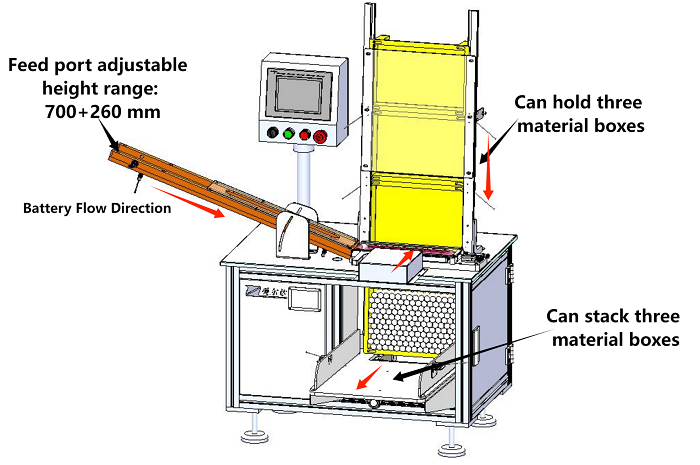

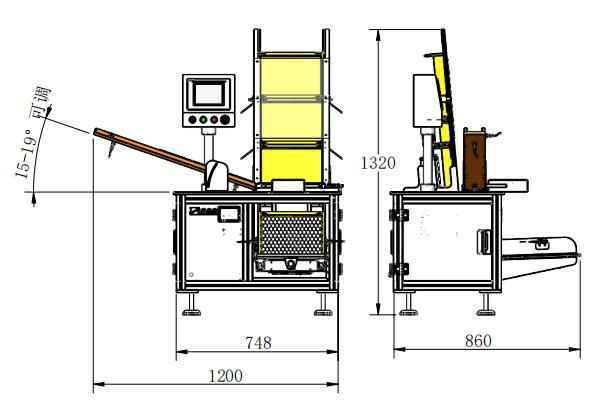

5.1 Downward Pull Type Sealing Machine

|

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

|

1 |

Suitable steel shell range |

18650 |

— |

|

2 |

Suitable height range |

60–80 mm |

— |

|

3 |

Rated voltage |

380V, 50 Hz |

— |

|

4 |

Rated power |

4 kW |

— |

|

5 |

Working air pressure |

5–6 kgf/cm² |

— |

|

6 |

Working efficiency |

50 pcs/min |

— |

|

7 |

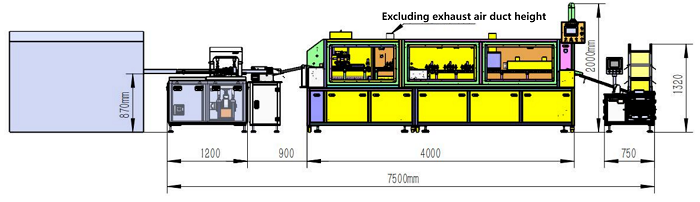

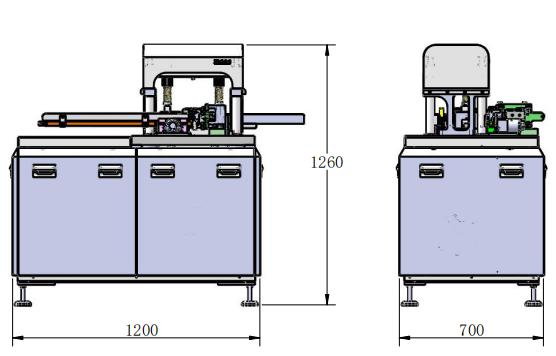

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

|

8 |

Equipment weight |

500 kg |

Actual weight may vary |

|

9 |

Counting function |

Real-time counting function |

— |

|

10 |

Product pass rate |

≥99.5% |

— |

|

11 |

Equipment utilization rate |

≥99% |

— |

|

12 |

Equipment failure rate |

<1% |

— |

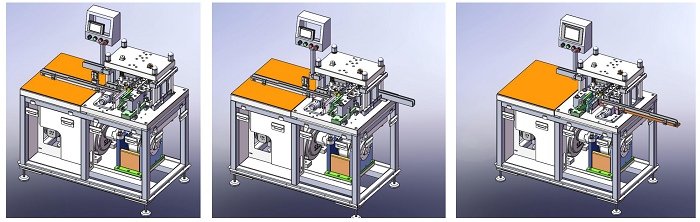

Feeding method:

To meet different customer requirements, our equipment can freely adjust the feeding and discharge method.

Right-in / Left-out Left-in / Right-out Left-in / Left-out

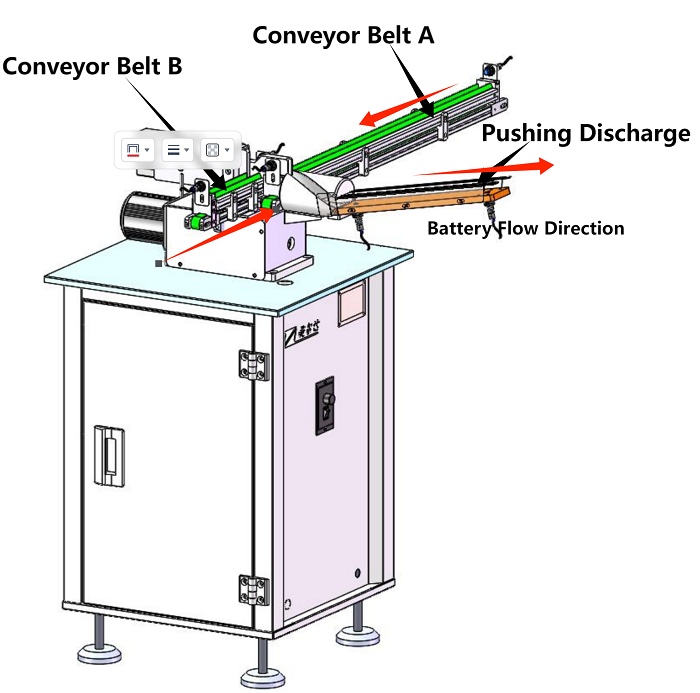

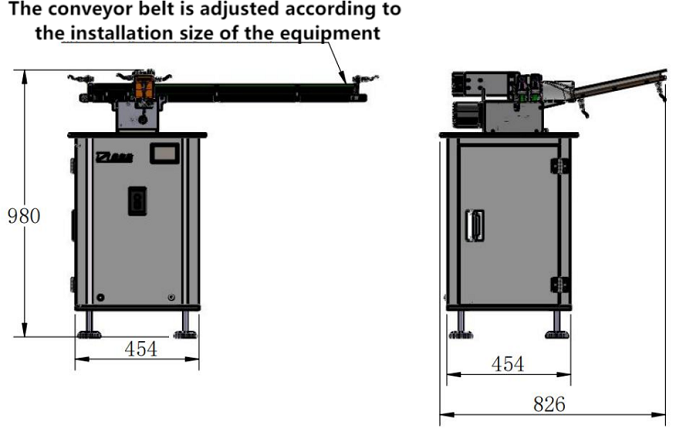

5.2 Docking Unit

|

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

|

1 |

Rated voltage |

220V, 50 Hz |

— |

|

2 |

Rated power |

60 W |

— |

|

3 |

Working air pressure |

5–6 kgf/cm² |

— |

|

4 |

Working efficiency |

>100 pcs/min |

— |

|

5 |

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

|

6 |

Equipment weight |

500 kg |

Actual weight may vary |

|

7 |

Counting function |

Real-time counting function |

— |

|

8 |

Product pass rate |

≥99.5% |

— |

|

9 |

Equipment utilization rate |

≥99% |

— |

|

10 |

Equipment failure rate |

<1% |

— |

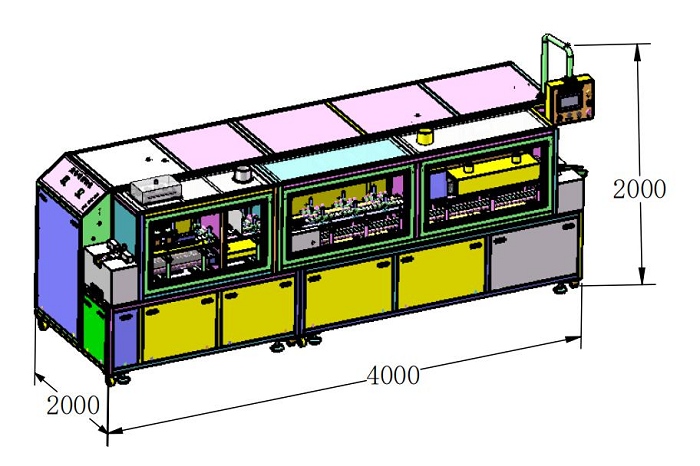

5.3 Automatic Cleaning Machine

|

No. |

Item |

Description |

Remarks |

|

1 |

Applicable range |

18650 steel shell battery |

— |

|

2 |

Equipment capacity |

>100 PPM |

— |

|

3 |

Equipment utilization rate |

≥98% |

— |

|

4 |

Product pass rate |

>99.5% |

— |

|

5 |

Working environment |

Temperature: 10–30°C, Humidity: 30–70% |

— |

|

6 |

Power supply configuration |

AC380V*5P / 50 Hz |

— |

|

7 |

Power |

20 kW |

— |

|

8 |

Equipment weight |

1954 kg |

— |

|

9 |

Overall dimensions (L×W×H) |

1200×4000×2000 mm |

— |

|

10 |

Compressed air |

≥0.6 MPa, 5 L/min |

— |

5.4 Automatic Boxing Machine

|

No. |

Equipment Parameter Name |

Parameter Description |

Remarks |

|

1 |

Applicable battery type |

18650 |

— |

|

2 |

Rated voltage |

220V, 50 Hz |

— |

|

3 |

Rated power |

600 W |

— |

|

4 |

Working air pressure |

5–6 kgf/cm² |

— |

|

5 |

Working efficiency |

>100 pcs/min |

— |

|

6 |

Overall dimensions (L×W×H) |

1200×700×1300 mm |

Actual size may vary |

|

7 |

Equipment weight |

500 kg |

Actual weight may vary |

|

8 |

Counting function |

Real-time counting function |

— |

|

9 |

Product pass rate |

≥99.5% |

— |

|

10 |

Equipment utilization rate |

≥99% |

— |

|

11 |

Equipment failure rate |

<1% |

— |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588