Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Wire Bar Coater: A Comprehensive Guide

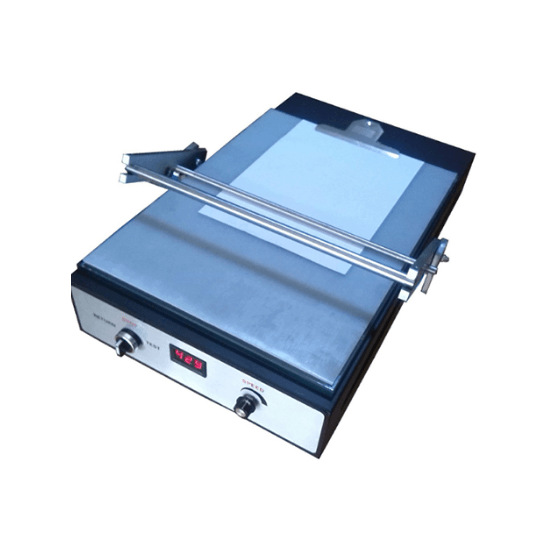

A wire bar coater is a specialized tool used in the coating process to apply thin, uniform layers of liquid materials onto flat substrates. It is widely employed in industries such as battery manufacturing, electronics, pharmaceuticals, and research laboratories for applications like electrode coating, film deposition, and surface treatment. Below is an indepth exploration of wire bar coaters, including their design, working principles, applications, advantages, and considerations.

●1. What Is a Wire Bar Coater?

A wire bar coater consists of a metal rod with a precisely machined wire wound around it in a helical pattern. The wire creates grooves that control the thickness and uniformity of the applied coating. When the wire bar is dragged across a substrate, it spreads the liquid material evenly, leaving behind a consistent layer.

●2. Key Components of a Wire Bar Coater

A. Wire Bar

A cylindrical rod with a helical wire winding.

The wire's diameter determines the thickness of the coating.

B. Substrate Holder

A platform or tray that secures the substrate during the coating process.

C. Liquid Reservoir

A container or trough that holds the coating material before application.

D. Handle or Mechanism

Allows the operator to drag the wire bar across the substrate manually or via automation.

●3. How Does a Wire Bar Coater Work?

1. Preparation:

Place the substrate on the holder.

Pour the liquid coating material into the reservoir or directly onto the substrate.

2. Application:

Drag the wire bar across the substrate at a steady speed.

The grooves in the wire pick up and distribute the liquid, creating a uniform layer.

3. Drying/Curing:

Allow the coated substrate to dry or cure according to the material's specifications.

●4. Types of Wire Bar Coaters

A. Manual Wire Bar Coaters

Operated by hand, suitable for smallscale or laboratory applications.

Simple and costeffective.

B. SemiAutomatic Wire Bar Coaters

Includes mechanical assistance for consistent speed and pressure.

Ideal for mediumscale production.

C. Fully Automatic Wire Bar Coaters

Computercontrolled systems for highthroughput operations.

Features advanced sensors and programming for precision.

●5. Applications of Wire Bar Coaters

A. Battery Manufacturing

Coating active materials onto aluminum or copper foils for cathodes and anodes.

B. Electronics Industry

Applying conductive inks or adhesives to circuit boards or flexible substrates.

C. Pharmaceutical Research

Depositing thin films for drug delivery systems or diagnostic devices.

D. Photovoltaics

Coating photoactive layers onto solar cells.

E. Laboratory Use

Preparing samples for testing and analysis.

●6. Advantages of Wire Bar Coaters

1. Uniform Coating:

Ensures consistent thickness across the substrate.

2. CostEffective:

Simple design and operation make it affordable for smallscale use.

3. Versatility:

Compatible with various liquids, including slurries, pastes, and solutions.

4. Ease of Use:

Requires minimal training for manual operation.

5. Scalability:

Available in manual, semiautomatic, and fully automatic configurations.

Lab Coating Machine

●7. Limitations of Wire Bar Coaters

1. Material Constraints:

Not suitable for highly viscous or solid materials.

2. Substrate Size:

Limited to flat, smooth surfaces; not ideal for curved or irregular shapes.

3. Precision Dependence:

Manual operation may introduce variability in coating thickness.

4. Maintenance:

Requires regular cleaning to prevent clogging and ensure accuracy.

●8. Factors Influencing Performance

| Factor | Impact on Performance |

|||

| Wire Diameter | Determines the thickness of the applied coating. |

| Speed of Application | Affects coating uniformity and thickness consistency. |

| Viscosity of Material | Higher viscosity requires adjustments in wire diameter and speed. |

| Substrate Surface Quality | Rough or uneven surfaces can affect coating uniformity. |

●9. Popular Manufacturers of Wire Bar Coaters

| Manufacturer | Key Features |

|||

| R.D. Specialties | Offers a wide range of wire bars and coating equipment. |

| BYKGardner USA | Provides highquality wire bars for industrial applications. |

| MTI Corporation | Specializes in battery manufacturing tools, including wire bar coaters. |

| Hohsen Corporation | Known for precision coating equipment for electrodes. |

●10. Maintenance Tips for Wire Bar Coaters

1. Regular Cleaning:

Clean the wire bar after each use to prevent residue buildup.

2. Inspection:

Check for wear or damage to the wire grooves, which can affect coating quality.

3. Storage:

Store wire bars in a clean, dry place to avoid contamination.

4. Calibration:

Periodically verify the wire diameter to ensure accurate coating thickness.

●11. Future Trends in Wire Bar Coaters

1. Automation:

Integration of robotics and automated systems for increased efficiency.

2. Smart Technology:

IoTenabled monitoring and realtime data analytics for process optimization.

3. Advanced Materials:

Development of coatings for new materials, such as solidstate electrolytes.

4. Sustainability:

Focus on reducing waste and improving resource utilization.

●12. Conclusion

Wire bar coaters are essential tools for achieving precise and uniform coatings in various industries. Their simplicity, versatility, and costeffectiveness make them a popular choice for both laboratory and industrial applications. By understanding their design, operation, and limitations, you can select the right wire bar coater to meet your specific needs.

If you're looking for guidance on choosing or using a wire bar coater, feel free to ask!

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588