Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

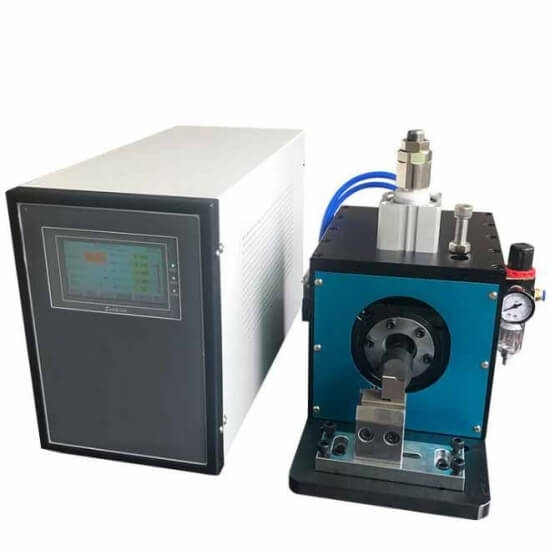

Ultrasonic Metal Welding Machine: A Comprehensive Guide

An ultrasonic metal welding machine is a specialized device that uses highfrequency vibrations to join metals without the need for external heat sources, filler materials, or adhesives. This technology is widely used in industries such as automotive, aerospace, electronics, and battery manufacturing due to its efficiency, precision, and ability to weld dissimilar metals.

Below is an indepth exploration of ultrasonic metal welding machines, including their working principles, applications, advantages, limitations, and key considerations.

●1. What Is an Ultrasonic Metal Welding Machine?

An ultrasonic metal welding machine generates highfrequency vibrations (typically 20–70 kHz) through a transducer and horn system. These vibrations are transmitted to the workpieces, creating friction at the molecular level. The resulting heat softens the metals locally, allowing them to bond together under pressure.

●2. How Does an Ultrasonic Metal Welding Machine Work?

A. Key Components

1. Power Supply (Generator):

Converts electrical energy into highfrequency electrical signals.

2. Transducer:

Converts electrical signals into mechanical vibrations using piezoelectric crystals.

3. Booster:

Amplifies the amplitude of the vibrations.

4. Horn (Sonotrode):

Transfers the amplified vibrations to the workpieces.

5. Anvil:

Holds one of the workpieces in place during welding.

6. Control System:

Monitors and adjusts parameters like frequency, amplitude, and pressure.

B. Working Process

1. The workpieces are placed between the horn and anvil.

2. The power supply activates the transducer, generating highfrequency vibrations.

3. The horn transmits these vibrations to the workpieces, creating frictional heat at the interface.

4. Under applied pressure, the softened metals intermix and form a strong bond.

●3. Types of Ultrasonic Metal Welding Machines

A. Handheld Ultrasonic Welders

Compact and portable, suitable for smallscale or onsite applications.

Often used in repair and maintenance tasks.

B. Benchtop Ultrasonic Welders

Designed for laboratory or smallscale production environments.

Provides precise control over welding parameters.

C. Industrial Ultrasonic Welders

Largescale systems for highthroughput production.

Includes automated features for consistent performance.

●4. Applications of Ultrasonic Metal Welding Machines

A. Automotive Industry

Joining aluminum components, such as heat exchangers and fuel lines.

Welding copper wires for electrical connections.

B. Aerospace Industry

Bonding lightweight materials like titanium and magnesium alloys.

Creating joints in structural components.

C. Electronics Industry

Assembling printed circuit boards (PCBs) and connectors.

Welding thin wires for sensors and actuators.

D. Battery Manufacturing

Joining tabs and terminals in lithiumion batteries.

Welding aluminum and copper foils for electrodes.

E. Medical Device Manufacturing

Fabricating implantable devices and surgical instruments.

Ensuring sterile and reliable connections.

Ultrasonic Metal Spot Welding Machine

●5. Advantages of Ultrasonic Metal Welding Machines

1. Energy Efficiency:

Requires less energy compared to traditional welding methods.

2. Precision:

Achieves accurate and repeatable welds with minimal material deformation.

3. No External Heat Source:

Reduces the risk of overheating sensitive components.

4. Versatility:

Can weld a wide range of metals, including aluminum, copper, nickel, and stainless steel.

5. Environmentally Friendly:

No use of consumables like fluxes, gases, or adhesives.

6. Fast Processing:

Weld cycles typically last only a few hundred milliseconds.

●6. Limitations of Ultrasonic Metal Welding Machines

1. Material Thickness Constraints:

Best suited for thin materials; thicker sections may require multiple passes.

2. Limited to Certain Metals:

Not effective for all metals, especially those with high hardness or low ductility.

3. Initial Cost:

High upfront investment for industrialgrade machines.

4. Complexity:

Requires skilled operators to optimize parameters for different materials.

5. Surface Preparation:

Clean, flat surfaces are necessary for optimal results.

●7. Factors Influencing Performance

| Factor | Impact on Performance |

|||

| Frequency | Higher frequencies result in finer welds but lower penetration. |

| Amplitude | Controls the intensity of vibrations; too high can damage materials. |

| Pressure | Affects bond strength; insufficient pressure leads to weak welds. |

| Material Properties | Hardness, ductility, and thickness influence weldability. |

| Joint Design | Proper overlap ensures uniform stress distribution. |

●8. Popular Manufacturers of Ultrasonic Metal Welding Machines

| Manufacturer | Key Features |

|||

| Branson Ultrasonics | Offers a wide range of ultrasonic welding solutions for various industries. |

| Sonics & Materials, Inc. | Known for highperformance benchtop and industrial systems. |

| Herrmann Ultrasonics | Specializes in advanced ultrasonic welding technologies. |

| Dukane Corporation | Provides customizable systems for specific applications. |

●9. Maintenance Tips for Ultrasonic Metal Welding Machines

1. Regular Cleaning:

Remove debris and contaminants from the horn, anvil, and other components.

2. Inspection:

Check for wear or damage to the horn and booster.

3. Lubrication:

Apply lubricants to moving parts as recommended by the manufacturer.

4. Calibration:

Periodically verify and adjust welding parameters for consistent results.

5. Training:

Ensure operators are trained to use the machine safely and effectively.

●10. Future Trends in Ultrasonic Metal Welding Machines

1. Automation:

Integration of robotics and AI for enhanced productivity and precision.

2. Smart Technology:

IoTenabled monitoring and predictive maintenance capabilities.

3. Advanced Materials:

Development of techniques for welding new materials, such as composites and nanomaterials.

4. Energy Efficiency:

Focus on reducing power consumption while maintaining performance.

●11. Conclusion

Ultrasonic metal welding machines offer a reliable, efficient, and environmentally friendly solution for joining metals across various industries. Their ability to create strong bonds without external heat or consumables makes them indispensable for modern manufacturing processes. While they come with certain limitations, advancements in technology continue to expand their capabilities and applications.

If you're considering purchasing or using an ultrasonic metal welding machine, carefully evaluate your requirements, budget, and longterm goals to select the right system for your needs.

For further details or assistance in choosing the best ultrasonic metal welding machine, feel free to ask!

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588