Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Hydraulic Heat Press: A Comprehensive Guide

A hydraulic heat press is a powerful industrial machine designed to apply both heat and pressure for bonding, laminating, or shaping materials. It uses hydraulic systems to generate consistent and uniform pressure, making it ideal for applications requiring highpressure conditions. This technology is widely used in industries such as automotive, aerospace, composites manufacturing, and textiles.

Below is an indepth exploration of hydraulic heat presses, including their working principles, types, applications, advantages, limitations, and key considerations.

●1. What Is a Hydraulic Heat Press?

A hydraulic heat press combines hydraulic force with controlled heat to bond, laminate, or shape materials. The hydraulic system ensures even distribution of pressure across the surface, while heating elements provide precise temperature control. This combination allows for strong, durable bonds between materials like metals, plastics, composites, and fabrics.

●2. How Does a Hydraulic Heat Press Work?

A. Key Components

1. Hydraulic System:

Uses hydraulic fluid and a pump to generate and distribute pressure.

2. Heating Elements:

Electric heaters or steam systems that maintain precise temperatures.

3. Press Plates/Platen:

Flat surfaces that apply pressure and transfer heat to the materials.

4. Control Panel:

Monitors and adjusts parameters like pressure, temperature, and cycle time.

5. Safety Mechanisms:

Includes emergency stop buttons, pressure relief valves, and thermal protection.

B. Working Process

1. The material to be bonded or shaped is placed between the press plates.

2. The hydraulic system applies uniform pressure across the plates.

3. Heating elements raise the temperature to the desired level.

4. The material is held under heat and pressure for a specified duration.

5. After cooling, the press opens, and the finished product is removed.

●3. Types of Hydraulic Heat Presses

A. Horizontal Hydraulic Heat Press

Plates are positioned horizontally, ideal for flat materials.

Commonly used in laminating, bonding, and composites manufacturing.

B. Vertical Hydraulic Heat Press

Plates are positioned vertically, suitable for taller or irregularly shaped components.

Often used in automotive and aerospace applications.

C. SingleActing Hydraulic Heat Press

Applies pressure in one direction only.

Simpler design, lower cost, and sufficient for many applications.

D. DoubleActing Hydraulic Heat Press

Applies pressure from both sides simultaneously.

Provides better control and uniformity, especially for thick or layered materials.

●4. Applications of Hydraulic Heat Presses

A. Automotive Industry

Bonding rubber components to metal parts (e.g., gaskets, seals).

Laminating composite materials for lightweight structures.

B. Aerospace Industry

Manufacturing composite panels and structural components.

Bonding advanced materials like carbon fiber and Kevlar.

C. Textile Industry

Printing designs on fabrics using heat transfer techniques.

Laminating protective layers onto textiles.

D. Electronics Industry

Encapsulating electronic components with thermoplastics.

Bonding circuit boards and connectors.

E. Construction Industry

Manufacturing laminated wood products like plywood and veneers.

Bonding insulation materials.

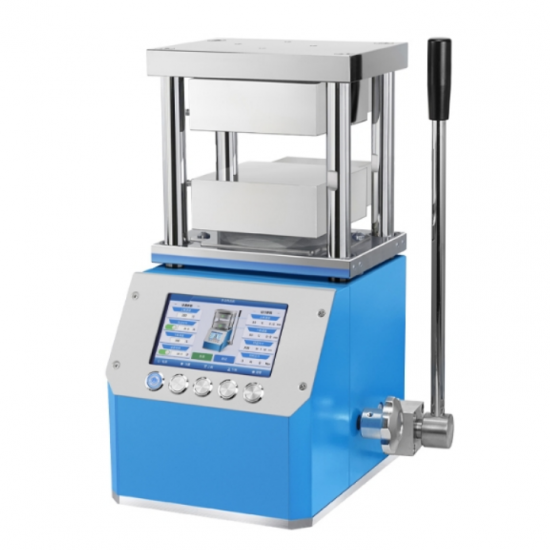

Maunal Heat Press

●5. Advantages of Hydraulic Heat Presses

1. Uniform Pressure:

Hydraulic systems ensure consistent pressure across the entire surface.

2. Precise Temperature Control:

Advanced heating elements allow for accurate temperature regulation.

3. High Capacity:

Capable of handling large or heavy materials with ease.

4. Versatility:

Suitable for bonding, laminating, shaping, and curing various materials.

5. Durability:

Built to withstand heavyduty industrial use.

6. Energy Efficiency:

Modern systems optimize energy consumption during operation.

●6. Limitations of Hydraulic Heat Presses

1. Initial Cost:

High upfront investment for industrialgrade machines.

2. Complex Maintenance:

Requires regular checks and servicing of hydraulic components.

3. Size Constraints:

Larger machines may require significant floor space.

4. Learning Curve:

Operators need training to effectively use and maintain the equipment.

5. Material Limitations:

Not all materials can withstand the high heat and pressure applied.

●7. Factors Influencing Performance

| Factor | Impact on Performance |

|||

| Pressure | Higher pressure improves bonding strength but must match material limits. |

| Temperature | Precise control ensures proper material activation without damage. |

| Cycle Time | Longer cycles improve bonding but reduce throughput. |

| Material Compatibility | Different materials require specific settings for optimal results. |

| Machine Size | Larger presses handle bigger jobs but may lack precision. |

●8. Popular Manufacturers of Hydraulic Heat Presses

| Manufacturer | Key Features |

|||

| Wabash Technologies | Specializes in largescale composite presses for aerospace and automotive. |

| Carver Inc. | Offers versatile hydraulic presses for laboratory and industrial use. |

| Thermwood Corporation | Known for advanced CNCintegrated hydraulic heat presses. |

| Hawe Hydraulic Systems | Provides customizable solutions for specific applications. |

●9. Maintenance Tips for Hydraulic Heat Presses

1. Regular Inspection:

Check for leaks in the hydraulic system and replace damaged seals promptly.

2. Fluid Management:

Maintain clean hydraulic fluid to prevent contamination and ensure smooth operation.

3. Heating Element Maintenance:

Clean and inspect heating elements to avoid uneven temperature distribution.

4. Lubrication:

Apply lubricants to moving parts as recommended by the manufacturer.

5. Calibration:

Periodically verify and adjust pressure and temperature settings for accuracy.

●10. Future Trends in Hydraulic Heat Presses

1. Automation:

Integration of robotics and IoT for increased efficiency and reduced labor costs.

2. Smart Technology:

Realtime monitoring and predictive maintenance capabilities.

3. Energy Efficiency:

Development of more energyefficient heating and hydraulic systems.

4. Advanced Materials:

Enhanced compatibility with new materials like graphene and nanocomposites.

●11. Conclusion

Hydraulic heat presses are indispensable tools for industries requiring precise bonding, laminating, or shaping under high pressure and temperature. Their ability to deliver uniform pressure and accurate temperature control makes them ideal for a wide range of applications. While they come with certain limitations, advancements in technology continue to enhance their performance and versatility.

If you're considering purchasing or using a hydraulic heat press, carefully evaluate your needs, budget, and longterm goals to select the right system for your operations.

For further details or assistance in choosing the best hydraulic heat press, feel free to ask!

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588