ItemNo :

LITH-J400D-BGAMOQ :

1Delivery Time:

5 days

Automatic Electrode Tab Laser Cutter for Lithium-Ion Battery Manufacturing

1.1 Function and Working Principle

This equipment is primarily used for the forming of tabs on lithium-ion battery electrodes.

It is designed for laser cutting of tabs on individual sheet electrodes and includes the following main functions: manual loading of electrodes, laser positioning, tab laser cutting, and manual unloading.

1.2 Workflow and General Structure

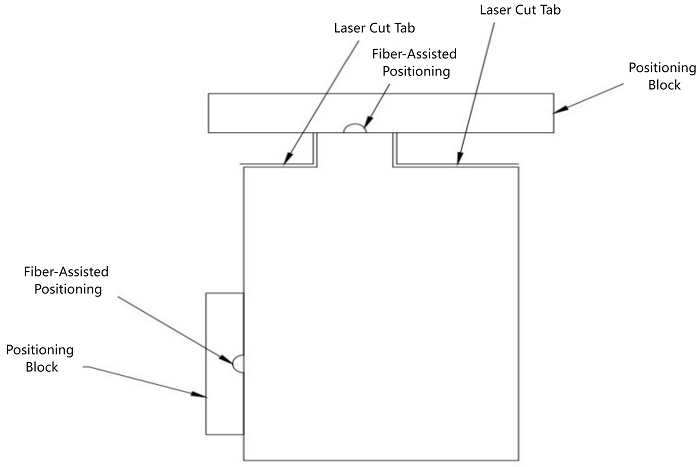

1.2.1 Workflow Diagram:

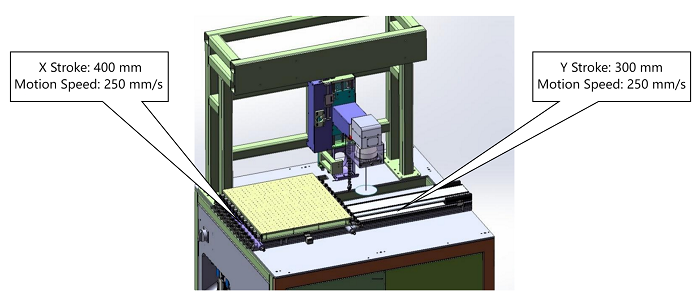

1.2.2 General Structural Diagram:

2.1 Applicable Incoming Material Specifications

|

No. |

Item |

Specification |

Remarks |

|

1 |

Material |

Cathode: LFP, NCM, etc. |

|

|

2 |

Anode: Graphite-based, Silicon-carbon-based, etc. |

|

|

|

3 |

Thickness |

50–200 μm |

|

|

4 |

Width (incl. tab) |

120–350 mm |

|

|

5 |

Foil Thickness |

Cathode: 8–15 μm; Anode: 6–8 μm |

|

|

6 |

Coating Type |

Continuous coating with tabs on both sides |

|

|

9 |

Serpentine Bending Deviation |

≤1.5 mm/m |

|

|

10 |

Waviness on Edge |

±1.5 mm |

|

|

11 |

Coating Width Edge Deviation |

±0.5 mm |

|

2.2 Electrode Forming Specifications

|

Item |

Specification |

|

W |

30–350 ±0.2 mm |

|

L |

30–350 ±0.2 mm |

|

H |

10–20 ±0.2 mm |

|

Q |

10–15 ±0.2 mm |

|

M |

20–60 ±0.2 mm |

|

X |

0–1 |

|

RA |

1.5–2 |

|

RB |

2–5 |

|

Horizontal Burr (Va) |

<25 μm |

|

Vertical Burr (Vb) |

<25 μm |

2.3 Tab-Cutting Mode

|

No. |

Item |

Specification |

Remarks |

|

1 |

Electrode Sheet Length |

30–350 mm (including tabs) |

|

|

2 |

Electrode Sheet Dimensional Accuracy |

±0.2 mm |

|

|

3 |

Molten Spheres Size |

≤15 μm |

|

|

4 |

Metal Exposure |

≤55 μm |

|

|

5 |

Heat-Affected Zone (HAZ) |

Cathode ≤100 μm; Anode ≤120 μm |

|

|

6 |

Power Supply |

AC 380V ±5%, three-phase, 50 Hz – Starting power ≤3 kW, Operating power ≤1.5 kW |

|

|

7 |

Cutting Speed |

250 mm/s |

|

|

8 |

Air Supply |

Compressed air 0.5–0.6 MPa; Air consumption: 1000 L/min |

|

|

9 |

Equipment Dimensions |

Approx. 1500 × 1500 × 2000 mm (main unit) |

|

|

10 |

Appearance Color |

Standard warm grey 1C; customized colors require color code samples |

|

|

11 |

Equipment Weight |

Approx. 800 kg |

|

|

12 |

Qualified Product Rate |

≥99.5% |

|

|

13 |

Equipment Failure Rate |

≤2% |

|

|

14 |

Ambient Operating Temperature |

0–50 °C |

|

Production Assembly Plant

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18659217588

+86 18659217588 18659217588

18659217588