- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-J520BS-BMOQ :

1Delivery Time:

5 days

Automatic Electrode Die Cutting Machine for Pouch Cells Production

1.1 Equipment Function Overview:

The J520BS-B electrode sheet machine is developed in response to the rapidly growing demand in the power battery market. It is a new type of equipment for precise die cutting and forming of roll materials, which saves labor, increases output, and reduces costs during production.

The launch of this product marks a major leap forward in the processing and die cutting forming of battery electrode sheets.

The overall design of the machine fully draws on advanced technologies and processes from both domestic and international sources, with high manufacturing precision and significant technical advantages.

Applicable for: Forming of lithium-ion battery cathode and anode sheets.

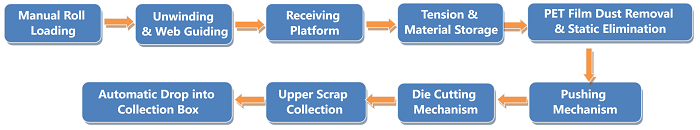

1.2 Functional Process:

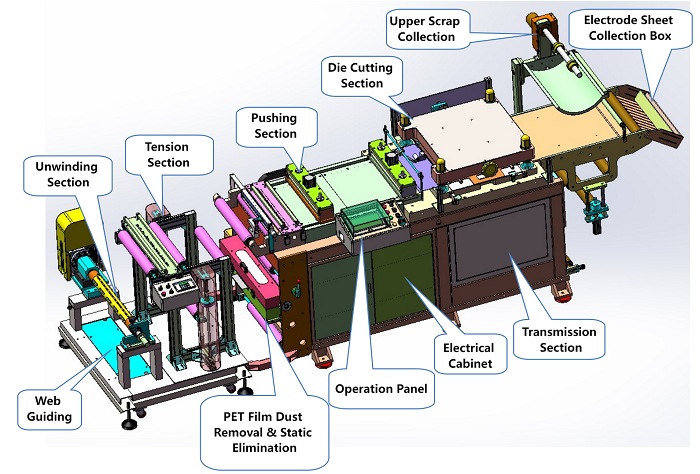

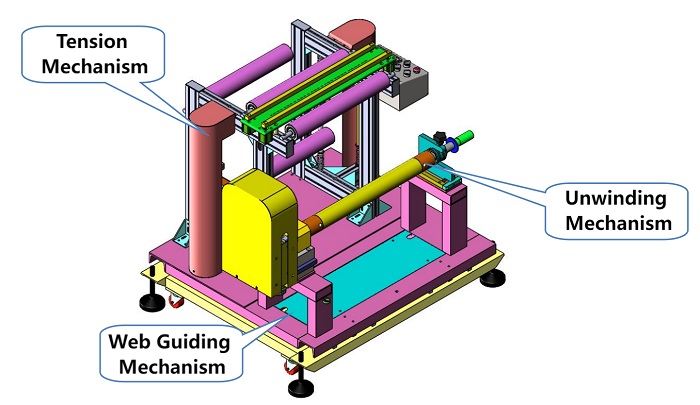

1.3 Equipment Schematic Diagram:

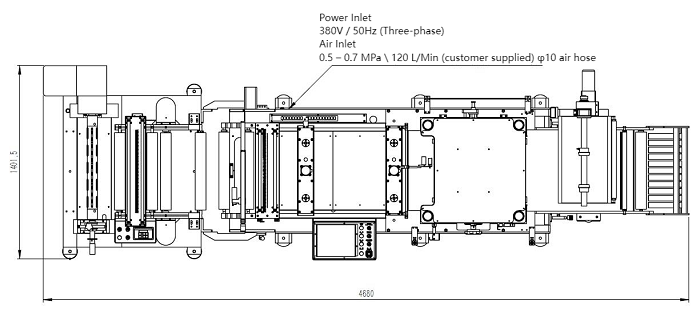

1.4 Equipment Layout Dimensions:

1.5 Equipment Features:

1. Use of this equipment allows for direct die cutting, reducing processes, reducing scrap, saving labor, materials, and time, minimizing material waste, and greatly improving production efficiency, electrode sheet quality, and investment cost.

2. Feeding method: Manual loading.

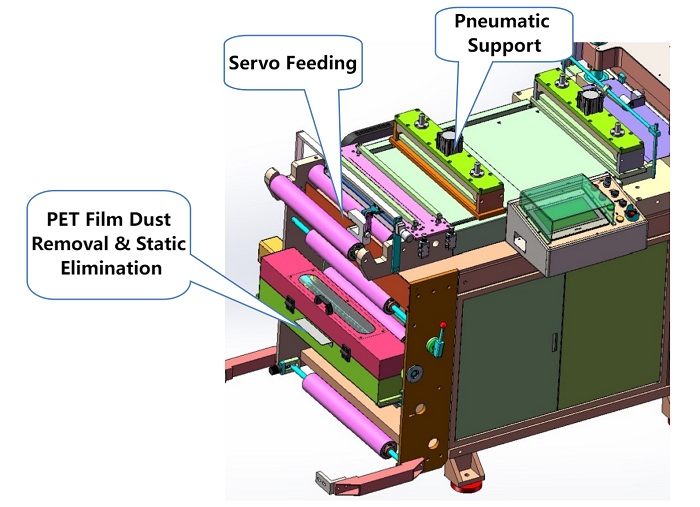

3. Uses a photoelectric sensing automatic web guiding system to correct material deviation, solving the problem of low product quality caused by material misalignment.

4. Feeding method: Pushed to the die cutting section by a servo motor with a precision ball screw; after punching and forming, materials are automatically fed out.

5. Operation section: Operated via a touch screen with program control; reasonable data can be set according to the product, making operation convenient and fast.

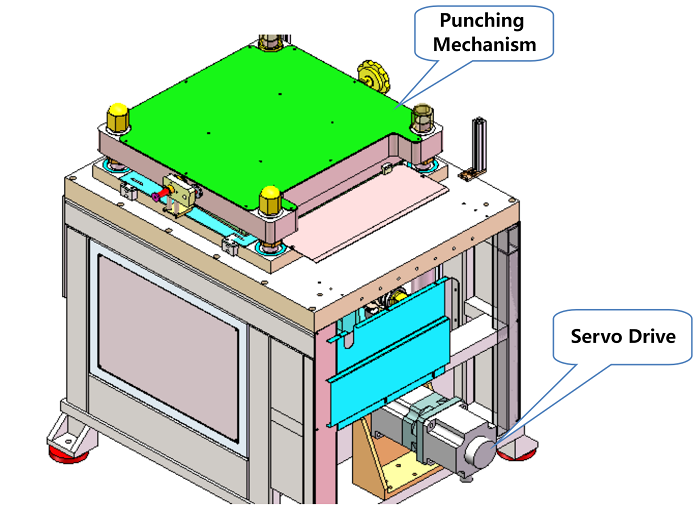

6. Die cutting section: Synchronized with the servo feeding speed; both upper and lower templates are made of cast steel material and undergo multiple stress relief and shaping processes to improve rigidity, parallelism, flatness, and pressure stability precision.

7. Transmission section: Driven by the main motor crankshaft motion, speed can be set according to different products, with stable pressure output to ensure production efficiency.

8. Lubrication method: Automatic oil supply control system to keep the equipment always lubricated and ensure stable die cutting pressure.

9. Forming method: Uses a laser knife die, capable of multi-sheet die cutting per stroke, with high production efficiency, low knife die cost, and quick, convenient changeover.

10. Monitoring method: Uses an advanced fault monitoring and alarm system; in case of a fault, the exact fault location can be accurately displayed on the touch screen, making maintenance convenient. The touch screen enables man-machine dialogue for easy operation.

11. Safety protection: Uses a sensitive light curtain sensor system to ensure operator safety, thereby preventing accidents and avoiding unnecessary losses for the company.

2.1 Applicable Incoming Material Dimensions

|

No. |

Item |

Parameter |

|

1 |

Incoming material width |

≤520 mm (including tabs) |

|

2 |

Incoming material thickness |

0.08 – 0.3 mm |

|

3 |

Incoming roll inner diameter |

3 inch |

|

4 |

Electrode sheet incoming roll outer diameter / weight |

≤500 mm / ≤150 kg |

|

5 |

Coating method and damage requirement |

Continuous coating, single-side tab, with tab damage < 0.5 mm |

|

6 |

Incoming winding neatness |

≤±1 mm |

|

7 |

Incoming material wave edge height |

≤0.5 mm |

|

8 |

Incoming coating width tolerance |

≤±0.5 mm |

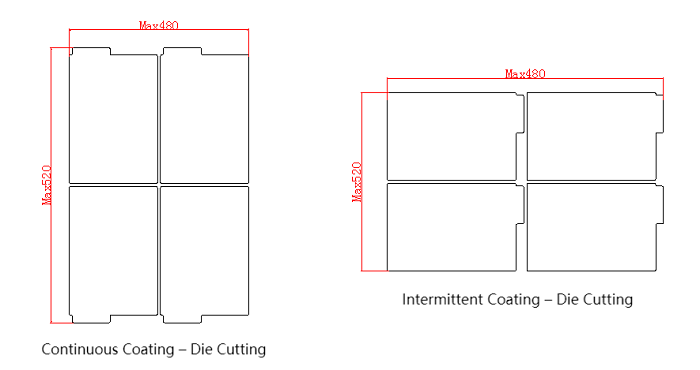

2.2 Electrode Sheet Die Cutting Method

Material specification: █ Cathode sheet / █ Anode sheet

Coating form: █ Continuous coating / █ Intermittent coating

|

Machine Model |

J520BS-B |

|

Effective die cutting area |

520 × 480 mm |

|

Maximum material width |

520 mm |

|

Knife die type |

Laser rubber plate knife die |

|

Knife die height |

8 mm |

|

Unwinding diameter |

Max. 500 mm |

|

Die cutting accuracy |

±0.3 mm |

|

Die cutting speed |

25 – 30 strokes/min (depending on material feed length) |

|

Sheet collecting method |

Automatic drop into material box |

|

Pressure adjustment method |

Automatic pressure adjustment |

|

Pressure adjustment range |

0 – 4 mm |

|

Pressure |

Approx. 15 T |

|

Scrap removal method |

Upper scrap collection |

|

Total power |

Approx. 10 kW |

|

Voltage |

380 V / 50 Hz (three-phase) |

|

Machine dimensions |

Approx. 4800 × 1500 × 1800 mm |

|

Machine weight |

Approx. 4000 kg |

|

Compressed air |

0.5 – 0.7 MPa / 120 L/min (customer supplied) φ10 air hose |

|

Ambient temperature |

1 ℃ – 40 ℃ |

|

Relative humidity |

< 93% |

|

Equipment color |

Warm Gray 1C (customer can provide color swatch) |

|

Equipment operating rate |

≥98% |

4.1 Unwinding Mechanism

a. Reel diameter up to 500 mm, capable of bearing electrode roll weight ≤150 kg.

b. Unwinding web guiding, guiding range ±50 mm, guiding accuracy 0.2 mm.

Main Structure:

|

No. |

Component |

Brand |

Remarks |

|

1 |

Air expansion shaft |

Self-made |

|

|

2 |

Unwinding web guiding |

Dongdeng |

Or equivalent brand |

|

3 |

Unwinding motor |

Domestic |

|

|

4 |

Support structure |

Self-made |

|

4.2 Pushing Mechanism

Main Structure:

|

No. |

Component |

Brand |

Remarks |

|

1 |

Pressing mechanism |

Self-made |

|

|

2 |

Pressing cylinder |

SMC |

|

|

3 |

Roller assembly |

Self-made |

|

|

4 |

Receiving platform |

Self-made |

|

|

5 |

Ball screw / Guide rail |

Hiwin |

Or equivalent brand |

|

6 |

Servo motor |

Domestic |

|

|

7 |

Static eliminator |

Domestic |

|

4.3 Die Cutting Mechanism

Main Structure:

|

No. |

Component |

Brand |

Remarks |

|

1 |

Linkage mechanism |

Self-made |

|

|

2 |

Support assembly |

Self-made |

|

|

3 |

Transmission assembly |

Self-made |

|

|

4 |

Knife die assembly |

Self-made |

|

|

5 |

Servo motor |

Domestic |

|

5.1 Main Accessories List:

|

No. |

Main Configuration |

Brand |

Origin |

|

1 |

PLC control system |

Trio |

UK |

|

2 |

Web guiding |

Dongdeng |

China |

|

3 |

Touch screen |

Weilen |

China |

|

4 |

Servo motor |

Domestic |

China |

|

5 |

Pneumatic components |

SMC / Airtac |

Japan / Taiwan |

|

7 |

Ball screw / Guide rail |

Hiwin |

Taiwan |

|

8 |

Electromagnetic clutch |

Yanxin |

China |

|

9 |

Color mark sensor |

Shenshi |

Japan |

|

10 |

Proximity switch |

Omron |

Japan |

5.2 Supplied Accessories List:

|

No. |

Name |

Specification / Model |

Quantity |

Remarks |

|

1 |

Laser knife plate |

Designed according to product model |

1 piece |

Electrode forming |

|

2 |

Conveyor belt |

Manufacturer customized |

1 piece |

Electrode conveying |

|

3 |

Commissioning tools |

— |

1 set |

As per packing list |

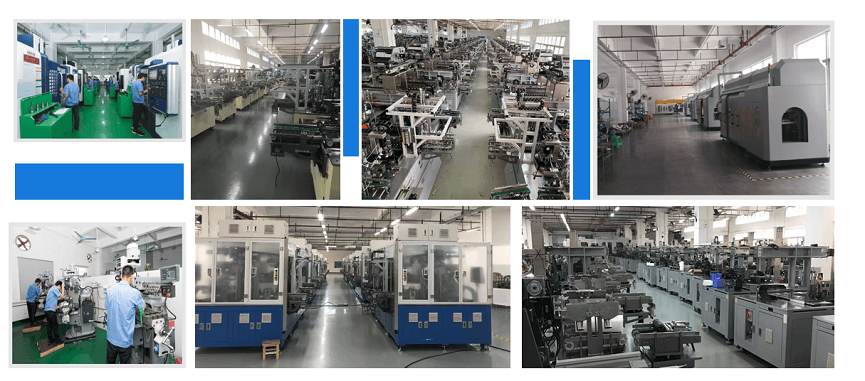

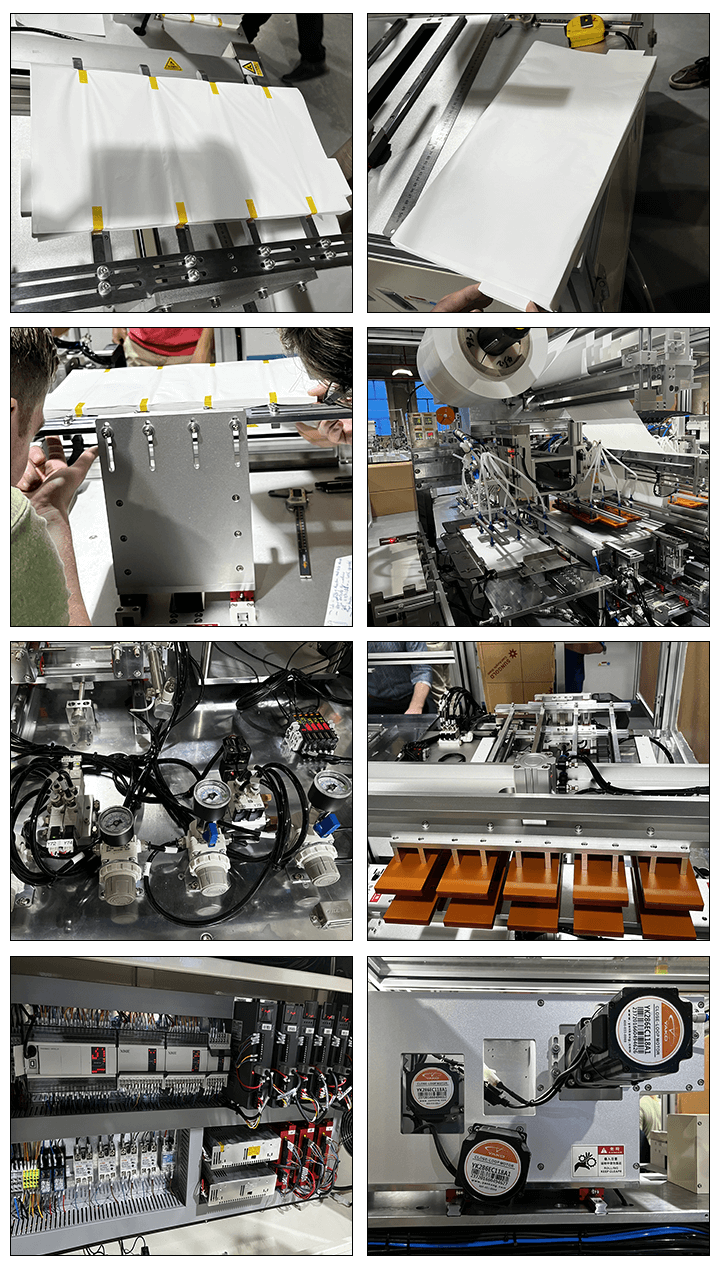

Production Assembly Plant

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588