ItemNo :

LITH-8000SL-IMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com8000 m³/h NMP Solvent Recovery System

|

Component Name |

Model |

Quantity |

Remarks |

|

NMP Solvent Recovery System |

LITH-8000SL-I |

1 set |

Recovery Rate: 99% ±3% Recovery Concentration: ≥80% Purification Concentration: <50 mg/m³ |

|

Built-in Spray Tower |

LITH-PLT |

1 set |

|

|

Cooling Water Tower |

LITH-30T |

1 set |

|

|

Liquid Storage Tank |

LITH-CYG |

1 unit |

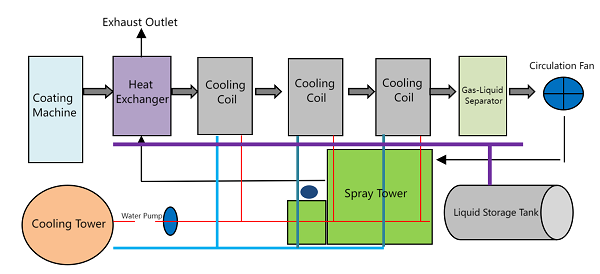

This system is used for recovering N-Methyl-2-pyrrolidone (NMP) from exhaust gases emitted by lithium-ion battery coaters. With low energy consumption, it cools the gas using circulating water and demists the exhaust before release. The final emission concentration is far below the national emission standards, ensuring environmental compliance, energy savings, and material reuse.

TMAX Series systems are designed for the lithium ion battery industry, particularly for handling NMP exhaust during the coating process.

· Combines water-cooling and spraying for efficient NMP gas treatment and purification.

· Simple operation with clear indicators.

· Modular design, easy to disassemble for maintenance.

· Efficient recovery, yielding high economic benefits for users.

|

Parameter |

Specification |

|

Organic Compound Emission Level |

<50 mg/m³ |

|

NMP Recovery Rate |

99% ±3% |

|

NMP Recovery Concentration |

≥80% |

· Ambient Temperature: +10~+40℃

· Relative Humidity: 20~90%

· Altitude: <1000 m

· Exhaust Gas Temperature: <120℃

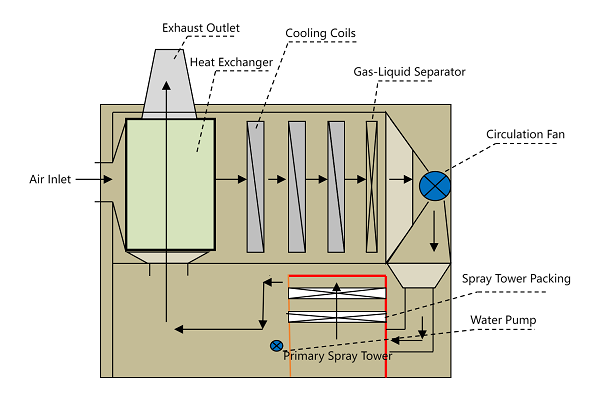

Machine Layout

|

No. |

Assembly |

Part Name |

Material |

Size/Model |

Manufacturer |

|

1 |

Main Unit |

Heat Exchanger |

Aluminum Tubes |

800×800×350 |

TMAX |

|

2-4 |

Main Unit |

Fin Cooler |

Copper & Aluminum |

800×800×200 (×3) |

ASD |

|

5 |

Main Unit |

Gas-Liquid Separator |

304 SS |

800×800×50 |

TMAX |

|

6 |

Main Unit |

Induced Fan |

Stainless Steel |

3kW |

Aozhong/Xinfeng |

|

7 |

Main Unit |

Casing |

201 SS |

1.5mm |

TMAX |

|

8-9 |

Outer Frame |

Structural Parts |

201 SS |

50×50×3 / 1.0mm |

Hongercheng/Dahua |

|

10 |

Spray Tower |

Tower Body |

201 SS |

1200×1000×1700×1.5mm |

Hongercheng/Dahua |

|

11 |

Spray Tower |

Packing |

304 SS |

800×800 |

TMAX |

|

12 |

Spray Tower |

Nozzle |

316 SS |

DN10 |

TMAX |

|

13 |

Water Pump |

Circulating Pump |

Anti-corrosive |

1.5 kW |

Yuanli |

|

14-15 |

Cooling System |

Cooling Tower / Fan |

Fiberglass / Cast Iron |

30T / 1.5kW |

Liangyuan |

|

16 |

Cooling System |

Circulating Pump |

Anti-corrosive |

2.2 kW |

Yuanli |

|

17 |

Liquid Storage |

Drainage Pipe |

Aluminum-Plastic |

2.0 |

Zeke |

|

18 |

Liquid Storage |

Storage Tank |

201 SS |

1.5T |

TMAX |

|

No. |

Item |

Model |

Qty |

Brand |

|

1 |

Air Switch |

4P/32A |

1 |

Chint |

|

2 |

Single Pole Switch |

1P/10A |

2 |

Chint |

|

3 |

AC Contactor |

1210 |

3 |

Chint |

|

4 |

Thermal Relay |

4A/6A |

3 |

Chint |

|

5 |

Indicator Light |

Red, Green |

2 |

Chint |

|

6 |

Selector Switch |

NP2 |

2 |

Chint |

|

7 |

Fuse |

6A |

1 set |

Chint |

|

8 |

Thermostat |

18/H |

2 |

Chint |

|

9 |

Alarm Light |

Ad16-22sm |

1 |

Chint |

|

10 |

Control Cabinet |

400×500×200 / 400×400×1500 |

1 each |

Chint |

|

Component |

Power |

|

Circulating Fan |

3 kW |

|

Circulating Water Pump |

2.2 kW |

|

Cooling Tower |

1.5 kW |

|

Spray Pump |

1.5 kW |

|

Liquid Pump |

0.55 kW |

|

Total |

8.75 kW |

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975