- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-06HMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

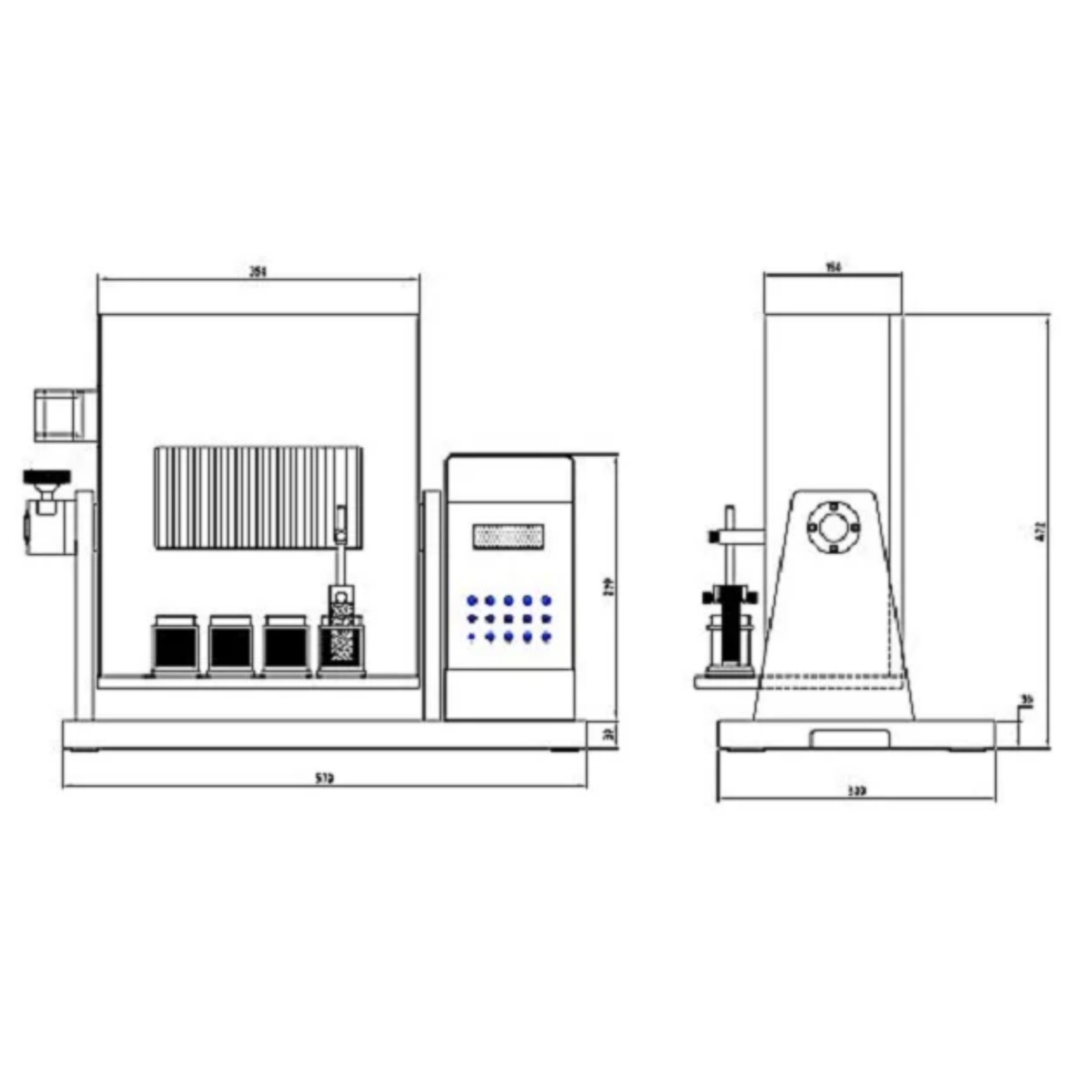

6-Position Programmable PLC Dip Coating System Coater With Stirrer & Heater For Metal Process

The TMAX-06H Coating System automates the entire SILAR process to eliminate operator fatigue and manual errors. Unlike manual dipping—which requires hundreds of repetitions and struggles with timing control—this system only requires the operator to clamp the substrate, program dip cycles, and set durations.

· Motorized substrate holder with adjustable dipping, stirring, and retrieval speeds.

· Six independent hot plates (up to 350°C each).

· Digital control for dip duration, dry time, stir speed, and temperature.

· Compatible with gloveboxes and fume hoods for controlled environments.

|

Parameter |

Specification |

|

Power Input |

208–240 VAC, 50/60 Hz |

|

Max Power Consumption |

600 W (with heater) |

|

110V Operation |

Requires 750W transformer (click left image to order) |

|

Actuator |

Stepper motor |

|

Drive Mechanism |

Lead screw |

|

Dip Duration |

0–99 sec/min/h |

|

Speed Control |

2–9000 µm/sec (digital adjustment) |

|

Number of Dips |

1–999 cycles |

|

Hot Plate Temperature |

Ambient to 350°C (6 independent plates) |

|

Recommended Beaker |

100 mL (50 mm OD) – not included |

|

Stirrer Speed |

1–200 RPM |

|

Thermocouple |

6 × K-type (built-in) |

|

Extension Sample Clip |

10 cm rod + 2 cm head |

|

Max Stroke Length |

75 mm |

|

Control Interface |

LED display (5-program memory) |

|

Temp. Control Accuracy |

±1°C (up to 350°C) |

|

Certifications |

UL (components >24V, excluding heater), CE |

|

Optional Certifications |

NRTL/CSA (available upon request) |

✔ For optimal coating:

· Pre-treat substrates with a plasma cleaner.

· Use an ultrasonic processor for nanoparticle dispersion.

✔ Environment options:

· Can be operated inside a glovebox (controlled atmosphere).

· Place in a fume hood if liquids emit vapor

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588