ItemNo :

LITH-LDDCF-590MOQ :

1Compliance:

Warranty:

Delivery Time:

5 daysEmail :

Louis@lithmachine.com

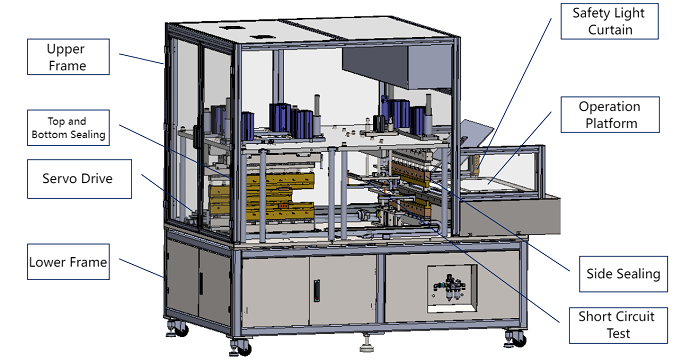

4-in-1 Pouch Battery Sealing and Short Circuit Testing System

1. Applicable for top, bottom, and side heat sealing of pouch-type liquid lithium-ion batteries, as well as short circuit testing (Three testing modes: positive & negative tab test, positive tab vs. pierced aluminum laminate, negative tab vs. pierced aluminum laminate)

2. Process Flow:

The battery with dual tab outlets is positioned within the upper and lower cavity jigs formed by aluminum laminated film. The operator places the jig into the moving mechanism. A servo motor drives the lead screw to precisely move the jig to the top/bottom sealing station, where the jig descends to perform top and bottom edge sealing.

After sealing, the jig ascends and is moved to the side sealing station, where it descends again to complete side sealing. Then the jig is transferred to the short circuit testing station, where the testing mechanism completes the circuit check.

Finally, the jig is returned to the loading station via servo drive. The operator removes and loads the jig for the next cycle.

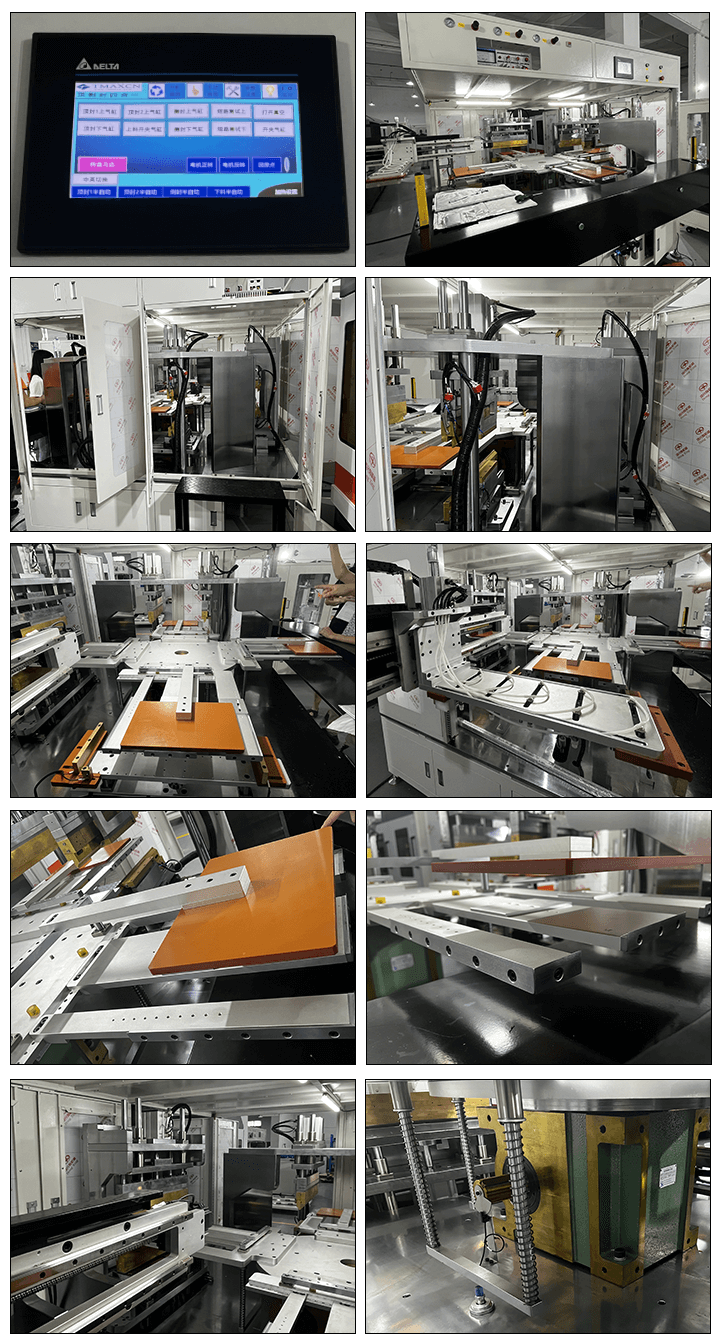

3. Equipment Diagram (Image for reference only)

1. Power Supply: AC220V / 50Hz

Rated Power: 7.0 KW

2. Compressed Air: ≥0.6 MPa, 20 L/min (provided by customer)

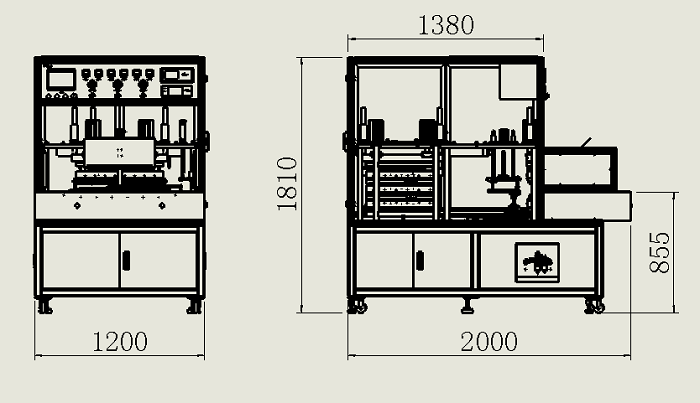

3. Machine Dimensions (L×W×H): Approx. 2000 mm × 1200 mm × 1810 mm

4. Machine Weight: Approx. 1400 kg

5. Paint Color: International Warm Gray 1C (or per supplier standard)

|

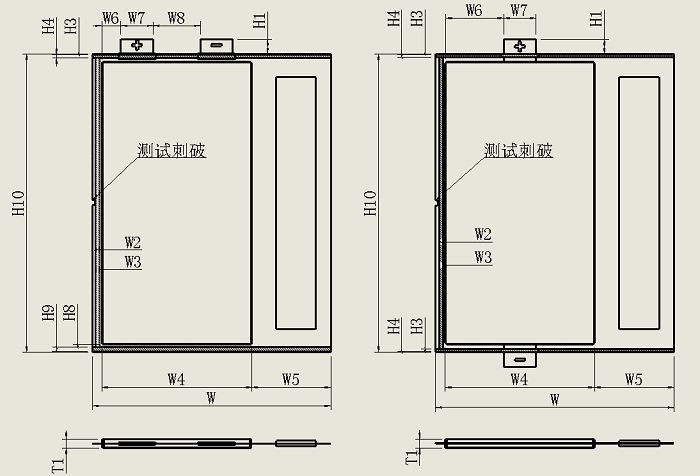

Item |

Value (mm) |

Item |

Value (mm) |

|

Top Seal Length W |

170–480 |

Cell Width W4 |

90–300 |

|

Top Unsealed Edge H3 |

1–3 |

Pouch Side Width W5 |

50–150 |

|

Top Seal Width H4 |

6 |

Cell Thickness T1 |

5–18 |

|

Bottom Seal Width H9 |

8 |

Tab Eccentricity (Cell Body) W7 |

5–80 |

|

Bottom Unsealed H8 |

0.5–2 |

||

|

Side Seal Length H10 |

90-600 |

Tab Width W7 |

30–100 |

|

Side Seal Width W2 |

8 |

Tab Center Distance W8 |

10–160 |

|

Side Unsealed Width W3 |

0.5–2 |

Tab Height H1 |

30 |

Reference Battery Dimensions:

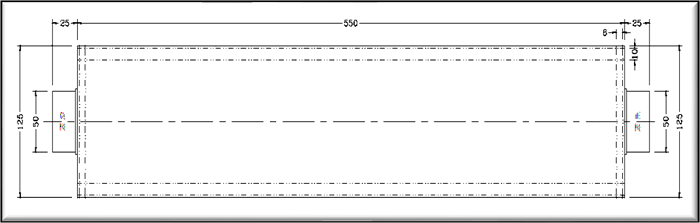

l Top Seal Strip: Length ≥280 mm, Width: 6 mm, Soft Seal

l Side Seal Strip: Length ≥580 mm, Width: 8 mm, Hard Seal

– Adjustable from ambient to 230°C, with compensation function

– Control Accuracy: ±2°C

– Sealing Time: 0–99.9 seconds adjustable

– Heat Sealing Temp Range: Ambient ~250°C, adjustable

– Temperature Uniformity: ±3°C

– Display Accuracy: ±1°C

– Testable with triplicate carbonless paper

– Under 0.6 MPa and 200°C, uniform sealing is expected

1. Linear servo-driven structure, high positioning accuracy

2. Jig lifting via pneumatic cylinder, fixed lower head, movable upper sealing head

3. Manual jig replacement enables fast switching

4. Manual loading of aluminum laminated film and battery cell

5. Comprehensive safety design:

– Dual-button start

– All moving parts enclosed within protective covers

6. PLC automatic control, HMI touchscreen interface for convenient operation

7. Production statistics, manual/automatic mode switching, fault alarm functionality

8. Safe, stable, reliable, and easy to operate

1. Battery positioning jig: Special clamping jig for battery loading/unloading, with rapid positioning

2. Jig transfer mechanism: Jig positioning with servo motor driving precision ball screw

3. Top & bottom sealing unit: Dual sealing structure, including cylinders, guide posts, copper heating blocks, insulation plates, sealing heads, and temperature control

4. Side sealing unit: Single side sealing with cylinders, guide posts, copper heating blocks, insulation plates, sealing head, and temperature control

5. Testing unit: Probe mechanism, puncture unit, cylinders, guide posts, testing platform, and short-circuit tester

6. Frame platform: Aluminum alloy frame, square tube welded structure, thickened chrome-plated steel plate platform, hardened chrome columns, and painted sheet metal covers

7. Control system: Includes PLC, HMI, cylinders, solenoid valves, servo motors, gear reducers, guide rails, and ball screws; with production statistics and fault alarm functions

1. Pneumatic Components:

– Taiwan brand cylinders, pressure regulators, pressure gauges, solenoid valves, pneumatic connectors

– PLC, touchscreen (includes timer, counter), safety light curtain, emergency stop, switch buttons

2. Standard Electrical Components:

|

Component |

Brand Options |

|

PLC |

Inovance / Panasonic / Omron |

|

HMI |

Weinview / Inovance / Omron |

|

Servo Motors |

Panasonic / Omron / Inovance |

|

Safety Light Curtain |

SICK / KEYENCE / Omron |

|

Electrical Components |

Chint / Schneider |

|

Solid-State Relays |

Omron / Honeywell / Siemens |

|

Solenoid Valves |

AIRTAC / CKD / Chint |

|

Cylinders |

AIRTAC / SMC / CKD |

|

Ball Screws / Guides |

HIWIN / TBI / THK |

|

Insulation Resistance Tester |

To be provided by customer |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975