- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-JBT-300LMOQ :

1Compliance:

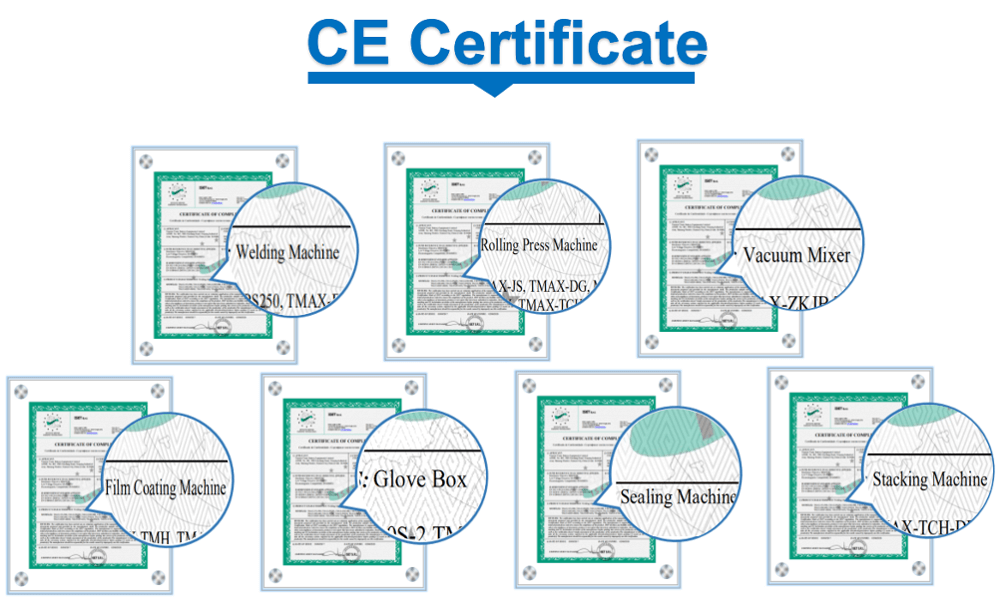

CEWarranty:

2 yearsDelivery Time:

5 days300L Industrial Vacuum Planetary Mixer for Viscous Materials

Application Scope

Once the slurry is prepared in the mixer, the tank is transferred to the lifting platform, where it is fitted with a mixing head to serve as a slurry transfer tank. It facilitates the movement of slurry from the mixing area to storage and coating zones, and uses quick-connect adapters to deliver slurry to the main tank or coater head.

Container Parameters

l Design Total Volume: 395 L

l Effective Volume: 130–300 L

l Inner Diameter: 836 mm

l Inner Depth: 720 mm

l Contact Material: SS304

l Jacket Type: Single layer on wall and bottom for heating/cooling

l Jacket Connection: G1″ quick connect, rated ≤ 0.4 MPa

l Jacket Circulation: Supplied by customer; inlet ≤ 8 °C, flow > 80 L/min

l Discharge: One G1 1/2″ three piece ball valve at bottom with 2″ ISO quick connect

l Ambient Temperature: –10 °C to +120 °C

l Mobility: Caster mounted

l Compatible with 300 L mixer bucket

Mixing Components

l Frequency: 50 Hz

l Mixer Power: 3.0 kW (1 unit)

l Mixing Speed: 30 rpm (fixed)

l Impeller Diameter: 776 mm

l Impeller Style: Inclined paddle screw

l Impeller Material: SS304

l Tip Speed: 1.2 m/s

l Impellers: 1

l Shafts: 1

l Clearance to Wall: 30 mm

l Clearance to Bottom: 10 mm

l Principle: Unique inclined paddle design prevents sedimentation

Top Cover Components

l Material: SS304

l Feeding Port: ISO quick connect 1″ (1 unit)

l Sight Glasses: DN100 tempered glass (2 units)

l Vacuum Port: G1″ quick connect (vacuum/vent)

l Digital Vacuum Gauge Port: M14×1.5 internal thread (1 unit)

l Control System

l Cabinet: houses inverter and low voltage devices

l Manual Panel: buttons, knobs, instruments

l Power: AC 3×380 V ±5%, 50 Hz

l Control Mode: electric

l Operation: cabinet panel buttons + knobs

l Emergency Stop: 1

l Start Button: 1

l Stop Button: 1

l Work light Switch: 1

Safety Interlock

Emergency Stop immediately halts all operations; no further action possible

Additional Notes

l Seals: domestic; static by O ring, dynamic by mechanical/skeleton seal

l Grease: domestic

l Valves: domestic

l Vacuum Requirement: customer provides ≥ 15 L/s (2×15) vacuum system

l Vacuum Retention: –0.098 MPa, holds > –0.085 MPa for 24 h without leakage

l Main Power: > 3 kW

l Weight: ~275 kg

l Dimensions: L11420 mm × W1088 mm × H1845 mm

l Color: Ivory white

l Floor Load Capacity: 600 kg/m²

|

No. |

Name |

Specification |

Material |

Qty |

Remarks |

|

1 |

Top lid sealing O ring |

ΦD×ΦN |

Silicone |

1 |

Matched to model, per supplier |

|

2 |

Sight glass sealing ring |

— |

Silicone |

2 |

Matched to model, per supplier |

|

3 |

Feed port gasket |

— |

Silicone |

1 |

Matched to model, per supplier |

|

4 |

Sight glass pane |

Tempered glass |

Glass |

2 |

Matched to model, per supplier |

|

No. |

Item |

Standard Requirement |

|

5 |

Workshop Height |

> 3.0 m; clearance for lift operation and maintenance; clean & level floor |

|

6 |

Door Size |

Height > 2.0 m; Width > 1.5 m; to allow equipment entry/exit |

|

7 |

Cooling Water |

Must meet heat load requirements; forced system preferred; hot water in winter |

|

8 |

Heating |

Maintain > 20 °C in winter to prevent hydraulic oil from gelling; ensure lubrication |

|

9 |

Installation Space |

As per layout drawing |

|

10 |

Air Supply |

5–7 kgf/cm², 50 L/min; for pneumatic operation |

|

11 |

Others |

No corrosive/explosive gases or liquids |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588