- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SEMS1100MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

2 daysSolid Electrolyte Test System

Introduction

LITH-SEMS1100 is a multifunctional analysis system for solid electrolyte test samples, is a fully automatic measuring device for the electrochemical performance of solid electrolyte that integrates tableting, testing and calculation. The system adopts integrated design, including pressurization module, electrochemical test module, compaction density measurement module, and clamp, etc., which is applicable to the test of various oxides, sulfides, polymers and other kinds of electrolytes.

Performance

1. New methods for evaluating ionic conductivity, electronic conductivity, and electrochemical performance of solid electrolytes;

2. New methods for testing various solid electrolytes such as oxides, sulfides, and polymers;

3. Multifunctional integrated equipment for tableting, electrochemical performance testing and calculation.

4. Large Pressure: Suitable for preparation of green pellet for oxide solid electrolyte;

5. Real-time Thickness Measurement: In-situ thickness measurement of solid electrolytes;

6. Sealed Mold: Suitable for testing of sulfide solid electrolytes in normal environments.

Application

1. Electrochemical stability window

2. Powder Tableting

3. Solid State Battery Cycle Performance

4. Electronic Conductivity & Compaction Density

5. Electronic conductivity

6. Ionic Conductivity

Description

1. The Importance of Electrochemical Performance of Solid Electrolyte

Driven by the rapid development of the lithium-ion battery (LIB) industry, improving the energy density and safety of the battery is an important research direction of for the LIB researchers. All-solid state battery is considered to be the most promising secondary battery with high safety and high specific energy in the future. Solid electrolyte (SE) is the most important core component, and the most important performance indicators used to judge the performance of solid electrolyte are ionic conductivity,Li-metal interface stability and full cell performance. On the one hand, the density, roughness and integrity of the pressed solid electrolyte sheet determine the conductivity of the solid electrolyte and the cycle performance of the full cell. On the other hand, the accuracy of the test results can only be guaranteed by the stable and uniform stress application and the accurate thickness measurement during the experiments. Therefore, the production and testing system that can exert stable and standardized pressure plays a key role in the development of solid electrolyte and lithium metal battery.

2. Limitations of Traditional Production and Traditional Testing

2.1 Traditional tableting

The traditional process generally uses a manual tablet press to press the solid electrolyte powder. The force of traditional manual method is uneven and cannot reach a high pressure, which will cause the thickness of SE sheet asymmetry with relatively low density, and finally trigger the depression, edge falling and fragmentation, etc., of the SE sheet after demoulding. Moreover, the traditional method need take a lot of time for the applying and releasing pressure, which seriously affects the experimental process and research efficiency.

2.2 Traditional test procedure

The traditional test method just simply holds the ceramic chip to measure the electrochemical properties. Because the force of the traditional test method is uneven, the maximum of the applied force is also limited, and the applied pressure cannot be quantified and maintained at a fixed value, the compression condition will exist great differences for samples with different thickness, area and roughness. Thus the experimental conditions cannot be normalized and standardized, and the measurement results will have poor consistency and low reproducibility.

2.3 Condition exploration

Traditional clamps or fixture cannot provide uniform, stable and variable pressure for the preparation of solid electrolyte sheets or the exploration of test conditions.

2.4 Measurement mode

Only constant pressure, non-quantifiable pressure, small pressure range, and unstable compression condition during the test.

3. Accurate Test Method for Solid Electrolyte by LITH

For the testing method of the ionic conductivity of the solid electrolyte, we refer to the LITH 019-2021 standard, and combine with ther the testing method of the ionic conductivity of the solid electrolyte, we refer to the TMAX 019-2021 standard, and combine with the general test process in the industry, including the standardization of sample preparation, fixture design, test device, and test conditions:

3.1 Sample preparation

1) Oxide materials must be subject to high-temperature crystallization treatment (generally above 900 ℃) to ensure good ion transport performance. Generally, the density of electrolyte sheet is>95%, and the thickness is>500 μm; In terms of electrode preparation, the electrode must be polished with sandpaper with more than 3000 meshes and sprayed with conductive gold of a certain thickness (>5 μm) , after which the good interface contact can be ensured. Grind the edge of the metal with sandpaper to prevent short circuit. Use a multimeter to ensure the electronic continuity between any two points on the surface.

2) The sulfide materials can directly be tested by cold compression process. During the test, a certain pressure (usually >200 MPa) must be guaranteed to ensure good ion transport performance.

3.2 Fixture design

A flat and compact contact surface, and a stable and uniform force application structure (quantifiable pressure) are required.

3.3 Test device

An electrochemical workstation system capable of measuring high frequency impedance (>1MHz) is required. A short lead with good signal shielding is also required

3.4 Test conditions

Select appropriate temperature and humidity, quantization pressure, frequency range and amplitude voltage.

For the electrochemical performance of solid lithium battery (charge-discharge cycle, electrochemical window), we combine the general test process in the industry, including the sample preparation, fixture design, test device, and standardization of test parameters.

3.5 Electrolyte preparation

1) Oxide materials must be subject to high-temperature crystallization treatment (generally above 900 ℃) to ensure good ion transport performance. Generally, the density of electrolyte sheet is>95%, and the thickness is>500 μm. It must be with strictly polished by the sandpapers.

2) During the direct cold pressure test of sulfide materials, a certain pressure (usually>200MPa) must be guaranteed to have good ion transport performance.

3.6 Electrode preparation

The positive electrodes shall be prepared by scraping, screen printing, sputtering deposition and other methods. The negative electrodes shall be prepared by surface treatment, melting, physical/chemical deposition, pressing and other methods to ensure good interface contact.

3.7 Fixture design

It needs a flat and compact contact surface, and a stable and uniform force application structure (quantifiable pressure).

3.8 Test conditions

Appropriate temperature and humidity, certain quantitative pressure, and strict sealing device.

4. Applications

Application Cases

Case 1. Formation of Green Pellet

The equipment can be used to prepare the green pellet of Oxide solid electrolytes.

Case 2. Ionic conductivity

Test Conditions:

EIS frequency band: 10MHz~0.1Hz

Voltage disturbance: 10mV

The electrochemical impedance spectroscopy (ElS) module automatically measures the ionic conductivity of polyelectrolytes under varying pressures

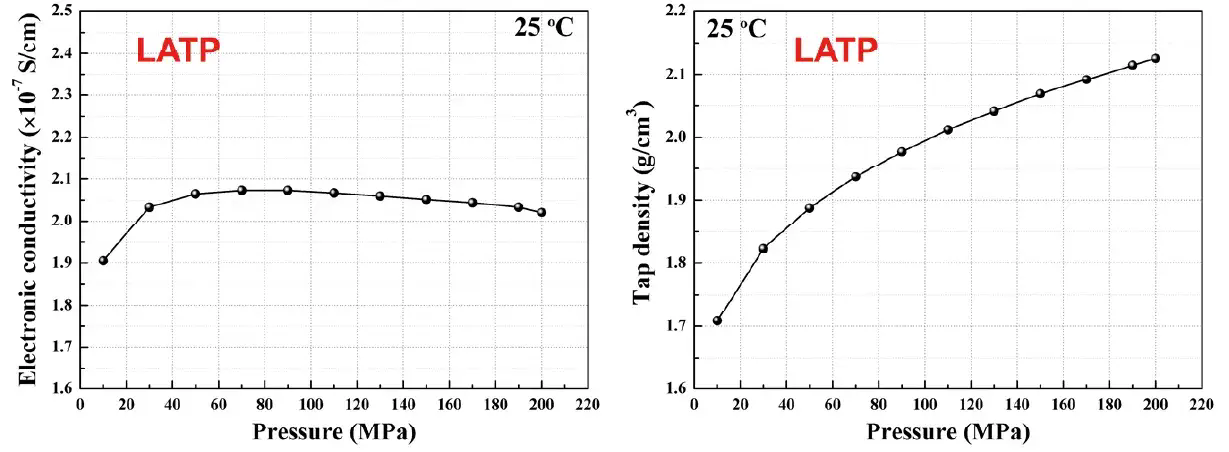

Case 3. Electronic conductivity & compaction density

The electronic conductivity of the solid electrolyte under varying pressures can be measured with an external electrochemical impedance spectroscopy (EIS) module.

Case 4. Solid state battery cycle performance

The charge-discharge (CD) module allows for the analysis of the cycling performance of solid lithium metal batteries under varying pressures and different electrochemical parameters.

Case 5. Electrochemical Stabilization Window

Using the cyclic voltammetry (CV) module, the electrochemical stability window of solid electrolytes can beanalyzed under different pressure conditions.

Specifications

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME: 15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588