- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-1004YZTSMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysSemi-Automatic Cylindrical Battery Electrode Winding Machine

This machine is mainly used for precision winding of cylindrical lithium-ion battery cells.

Process: The operator manually feeds the positive and negative electrode sheets into the winding section. The sheets are interleaved with the separator and wound according to process requirements. The machine then automatically applies termination tape and automatically discharges the wound cell.

*Features a single-needle axial winding structure.

*Process flow: Manual electrode loading → automatic winding → automatic needle replacement → automatic termination tape application → automatic unloading.

*Adopts horizontal application of termination tape (perpendicular to electrode tabs), ensuring flatness, precise positioning, no over-tightening of the battery, and stable, reliable performance.

*Winding needle speed is adjustable.

*Equipped with dual separation rollers for active rewinding; proximity switch-based tension control enables smooth automatic adjustment, with support for both upward and downward tension regulation.

*The separator is wrapped to achieve a smooth finished surface.

*Finished batteries are free from damage, core displacement, or electrode misalignment.

*Offers user-friendly operation and quick specification switching.

The machine meets cylindrical-cell winding standards (separator fully wraps anode; anode wraps cathode).

1. Separator pre-winding — toothed-blade method saves separator length.

2. Feed anode manually → Feed cathode manually.

3. Winding.

4. Work-position transfer.

5. Separator cutting → termination-tape application → cell discharge.

|

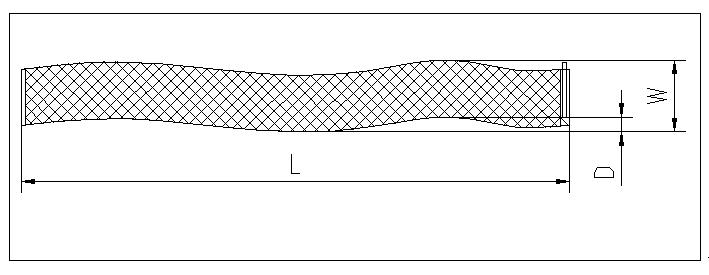

|

W |

D |

L |

|

Tolerance |

< 0.5 |

< 0.3 |

< 1000 |

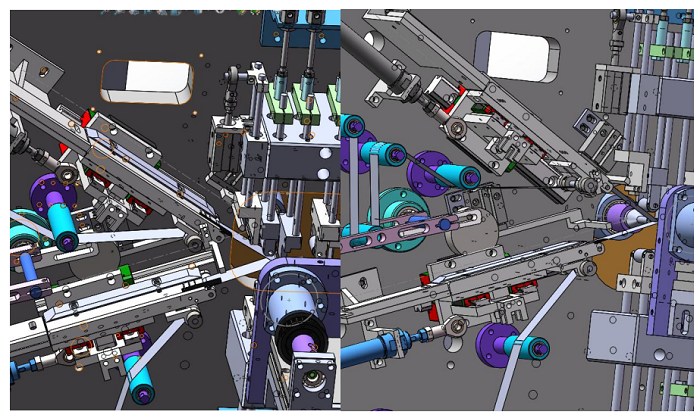

· The machine consists of winding units, position transfer unit, separator unwinding units, electrode guide units, automatic feeding units, tape application unit, discharge unit, and control system.

· Winding units (2 sets): single head through shaft design ensures precision; needles can be replaced easily.

· Position transfer unit (1 set): switches between winding station and taping station.

· Separator unwinding units (2 sets): active unwinding with pneumatic tension control.

· Electrode guide units (2 sets): single side adjustable, easy fine tuning.

· Tape application & discharge unit (1 set).

· Automatic feeding units (2 sets):

· Operator places sheets on the feed plate; cylinders position them.

· A cylinder pushes the sheet along a guide rail to the winding point.

· During winding, cylinders press the electrodes to ensure uniform pressure.

· Cylinder feeding guarantees identical sheet position and pressure, ensuring consistent tab location, thickness, and sheet length (assuming material consistency).

Material

Length

Width

Thickness

Inner Ø

Outer Ø

Cathode sheet

40 – 800

2.5 – 8

0.1 – 0.2

—

—

Anode sheet

40 – 800

2.5 – 8

0.1 – 0.2

—

—

Separator (roll)

—

3 – 10

0.010 – 0.045

76.2

250

Termination tape (roll)

—

3 – 9

0.01 – 0.035

76.2

150

|

Item |

Specification |

Remarks |

|

Power supply |

AC 220 V, 1.5 kVA, 50 Hz |

|

|

Compressed air |

0.4 – 0.6 MPa |

|

|

Rated capacity |

8 pcs/min |

|

|

Weight |

≈ 500 kg |

|

|

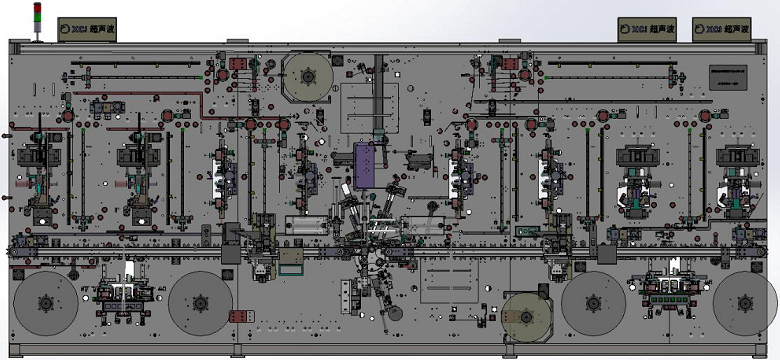

Dimensions |

1660 × 1300 × 1570 mm (L×W×H) |

Electrode‑tray overhang not included |

|

Winding needle |

∮1.2mm-∮4.0mm |

One set supplied (others per customer) |

|

Frame & mounting plate |

1 set |

|

|

Winding assembly |

1 set |

|

|

Electrode-feeding unit |

2 sets |

|

|

Separator-feeding unit |

2 sets |

|

|

Tape-application unit |

1 set |

|

|

PLC |

Panasonic |

AFRX-C60T |

|

Touchscreen |

MCGS |

7-inch true-color |

|

Winding motor |

Panasonic / Lishan |

servo (hybrid stepper) |

|

Tension motor |

YANKONG / Lishan |

Stepper |

|

Sensors |

Panasonic / JYC |

|

|

Pneumatics |

AIRTAC / XINGZHEN / Airtac |

|

|

Main switch |

CHINT – leakage-protection breaker |

|

|

Alarm system |

Fault stop, built-in prompts, one-key reset |

|

|

Operation manual |

1 set |

|

|

Spare-parts kit |

1 set (see delivery list) |

|

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588