- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-KJ01NOMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

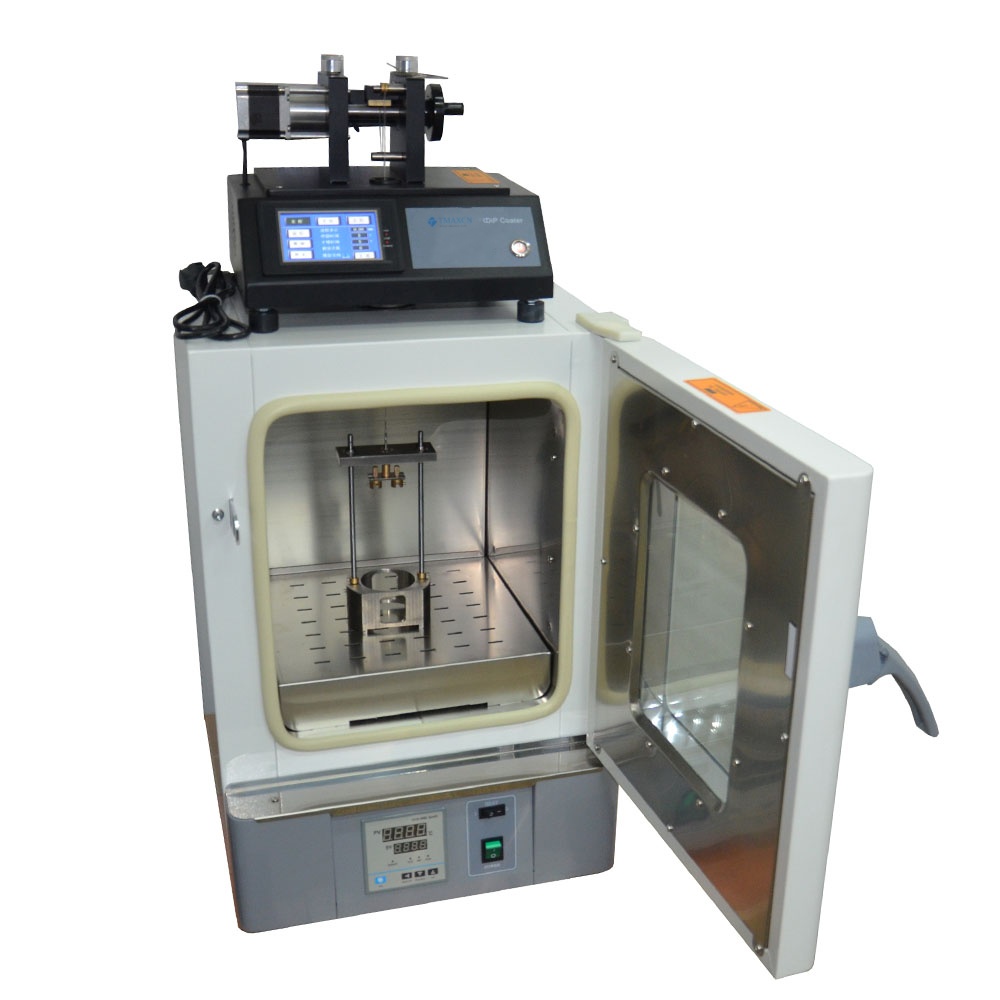

Nano-Level Constant Temperature Dip Coater With Oven

The LITH-KJ-01NO Nano-Level Constant Temperature Dip Coater is a CE-certified precision instrument designed for liquid-phase dip-coating experiments at the nanometer scale. It is an indispensable tool for thin-film growth research in academic and industrial laboratories.

This system features a PLC-programmable control unit paired with a high-precision stepper motor, ensuring smooth and accurate vertical motion via a suspended wire transmission mechanism. Samples are immersed in liquid-phase thin-film materials and withdrawn at controlled speeds to deposit uniform coatings with adjustable thickness.

Key operational modes:

· Single Cycle: One immersion/withdrawal sequence.

· Full Cycle: Programmable repeated cycles (1–20×).

User-defined parameters include:

· Lifting/immersion speeds (1–500 nm/s)

· Dwell time (1–999 s)

· Drying time (1–999 s)

The integrated constant-temperature heating chamber (RT to +100°C) ensures process stability. Compact and user-friendly

Key Features

· 4.3-inch color touchscreen with an intuitive interface, suitable for beginners.

· Compact design, high cost-performance ratio, and space-saving for laboratory use.

· PLC-controlled high-precision stepper motor drive with suspended wire transmission for vibration reduction.

Technical Parameters

|

Category |

Specifications |

|

Model |

Lith-KJ-01NO |

|

Installation Requirements |

1. Power Supply: AC220V 50/60Hz, 10A standard socket with proper grounding. |

|

|

2. Ambient Conditions: Temperature 25°C ±15°C, Humidity 55%Rh ±10%Rh. |

|

Main Parameters |

1. Operating Voltage: DC24V 3.75A (Included: AC100~240V power adapter) |

|

|

2. Power Consumption: 50W |

|

|

3. Type: Programmable—Constant Temperature (with heating chamber) |

|

|

4. Drive Motor: High-precision stepper motor |

|

|

5. Speed Range: 1–500nm/s |

|

|

6. Dwell Time: 1–999s |

|

|

7. Drying Time: 1–999s |

|

|

8. Lifting Stroke: 1–75mm |

|

|

9. Coating Cycles: 1–20 times |

|

|

10. Max Immersion Depth: ≤60mm |

|

|

11. Load Capacity: <100g |

|

|

12. Sample Substrate Size: 75mm × 25mm × 2.5mm (2 pieces simultaneously) |

|

|

13. Control Interface: 4.3-inch color touchscreen |

|

|

14. Heating Chamber Specifications: |

|

|

- Operating Voltage: AC220V 50/60Hz |

|

|

- Rated Current: 3.6A |

|

|

- Heating Power: 0.8KW |

|

|

- Temperature Range: RT to +100°C |

|

|

- Temp. Control/Setting: Dual-digit PID display, 4-button setting |

|

|

- Timer: 0–9999 minutes/hours |

|

|

- Internal Dimensions (Capacity): 310mm × 310mm × 310mm (30L) |

|

|

- External Dimensions: 428mm × 500mm × 723mm |

|

|

15. Product Specifications: |

|

|

- Dimensions: 428mm × 500mm × 995mm |

|

|

- Weight: ≈50kg (including heating chamber) |

|

Notes |

1. Default power adapter specifications: Input: AC100-240V 50/60Hz, Output: DC24V 3.75A. Actual power supply must match the label on the device. |

|

|

2. Customizable AC110V 50/60Hz heating chamber available. |

Standard Accessories

|

No. |

Item |

Quantity |

|

1 |

Coating Clamp |

1 set |

|

2 |

Material Cup |

1 pc |

|

3 |

Lifting Wires |

3 pcs |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588