- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SFZ200MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysNa-ion Cell Heat Sealer Machine For Battery Top & Side Sealing

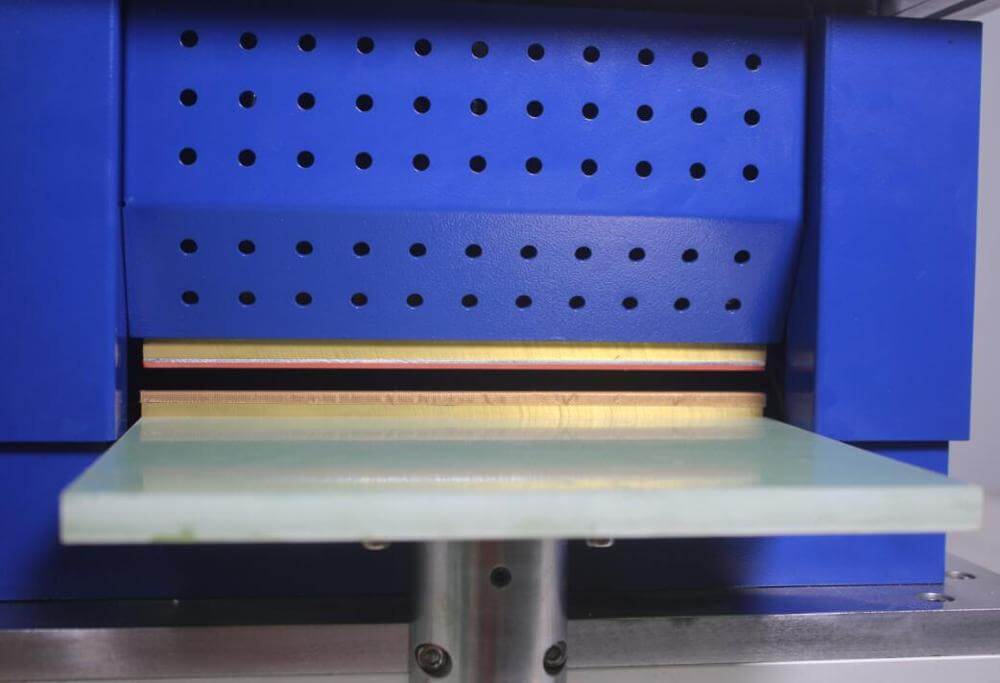

The Pouch Cell Heat Sealing Machine is designed for top-edge and side-edge sealing of pouch cell lithium-ion batteries. The machine uses a heating tube to transfer heat to the copper sealing head, which applies heat conduction to the aluminum laminated film of the battery. Under controlled pressure, the material softens and approaches a molten state, enabling secure and uniform sealing.

· Temperature-controlled sealing heads, regulated by a thermocouple and temperature controller to maintain a stable temperature.

· Built-in pressure gauge, allowing precise control of sealing pressure.

· Firm, uniform, and smooth sealing, ensuring aesthetic and durable seals.

· Unique safety protection and anti-scalding design, ensuring safe operation.

· Energy-efficient, consuming 50% less energy compared to similar products.

· No mold change required for switching between top and side sealing.

· Compact, easy-to-operate, and reliable design, suitable for various lab and production environments.

|

Parameter |

Specification |

|

Sealing Head Length |

≤300mm |

|

Sealing Width |

Standard: 5mm (customizable) |

|

Sealing Thickness |

0.15~0.3mm |

|

Applicable Sealing Size |

Side Seal ≤ 300mm, Top Seal ≤ 300mm (including gas bag, customizable) |

|

Upper Mold Temperature |

Max. 300℃ (Recommended: 200℃) |

|

Lower Mold Temperature |

Max. 300℃ (Recommended: 100℃) |

|

Sealing Pressure |

0.5-0.7MPa (adjustable) |

|

Sealing Time |

Standard: 2-3s (Adjustable: 0-99s) |

|

Power Supply |

AC220V / 50Hz |

|

Power Consumption |

1000W |

|

Machine Dimensions |

L420xW420xH500mm |

|

Machine Weight |

40kg |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

|

|

|

|

|

|

|

|

|

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588