- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SABPMOQ :

1Color :

optionalPort :

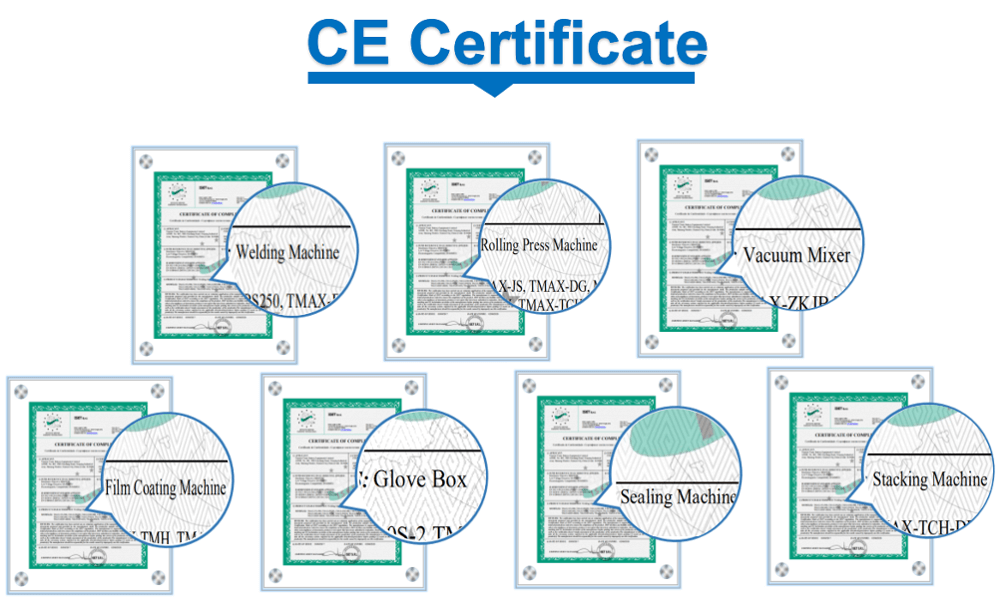

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEnergy Storage/ Electric Scooters/ Solar Light/ Power Battery Pack Assembly Plant

Introduction

The process of assembling lithium battery cells into a group is called pack, which can be a single battery or a series parallel battery module.

Pack consists of battery pack, bus bar, soft connection, protection board, outer package, output (including connector), highland barley paper, plastic cell holder and other auxiliary materials.

Features of pack

1. Pack of battery pack requires high consistency of battery (capacity, internal resistance, voltage, discharge curve, life).

2. The cycle life of battery pack is lower than that of single battery.

3. Using under limited conditions (including charging, discharging current, charging mode, temperature, etc.).

4. The voltage and capacity of lithium battery pack have been greatly improved after forming, so it must be protected and monitored for charge balance, temperature, voltage and overcurrent.

5. The battery pack must meet the voltage and capacity requirements required by the design.

Pack method

1. Series parallel composition:

The battery is composed of single battery through parallel series connection.

When the capacity is increased in parallel, the voltage does not change.

After the series connection, the voltage multiplies and the capacity does not change.

For example, 3.6v/10ah battery is composed of a single N18650 / 2Ah through 5.

Parallel before series: due to the difference of internal resistance and uneven heat dissipation, parallel will affect the cycle life of battery.

However, the failure of a single battery automatically exits, in addition to capacity reduction, which does not affect the use of parallel, parallel technology is relatively strict.

When a unit battery in parallel is short circuited, the current of parallel circuit is very large, which is usually avoided by fuse protection technology.

Series before parallel:

According to the capacity of the whole battery, series connection is carried out first, for example, the capacity of the whole battery is 1 / 3, and then parallel connection is carried out to reduce the failure probability of large capacity battery.

2. Requirements for electric core:

Select corresponding electric core according to the design requirements.

The parallel and series batteries shall have the same type and model, and the difference in capacity, internal resistance and voltage value shall not be greater than 2%.

In general, the capacity loss of the battery is 2% - 5% when it is combined in series and parallel.

The more the number of batteries, the more the capacity loss.

No matter it is a soft packed battery or a cylindrical battery, it needs to be combined in multiple strings. If the consistency is poor, the battery capacity will be affected.

The battery with the lowest capacity in a group determines the capacity of the whole group of batteries.

High current discharge performance is required.

The starting current of the motor is three times of the normal working current, and the power performance of the motor can be improved only when the large current is discharged.

Good heat dissipation of battery is required.

The number of batteries is large, and the temperature rise of the batteries inside the battery box is not easy to disperse, resulting in uneven temperature and different discharge characteristics among the batteries, resulting in long-term degradation of battery performance. High level of production technology.

The battery shall be able to withstand the vibration impact of bumpy road.

It has a high demand for production technology, especially spot welding technology.

Test shall be conducted after welding to prevent faulty welding and desoldering.

Others

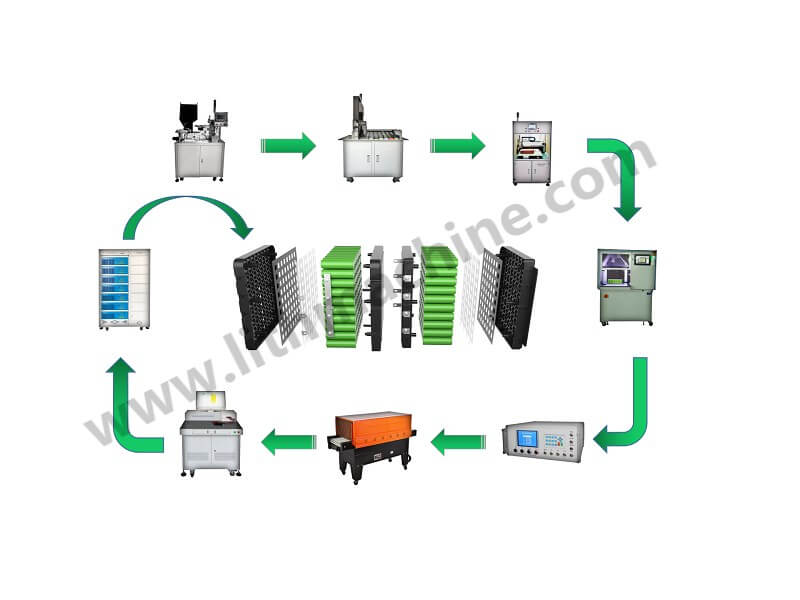

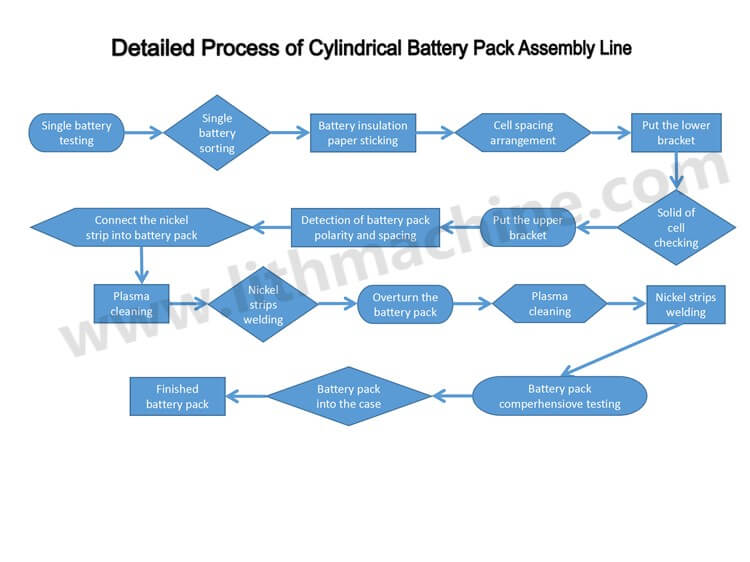

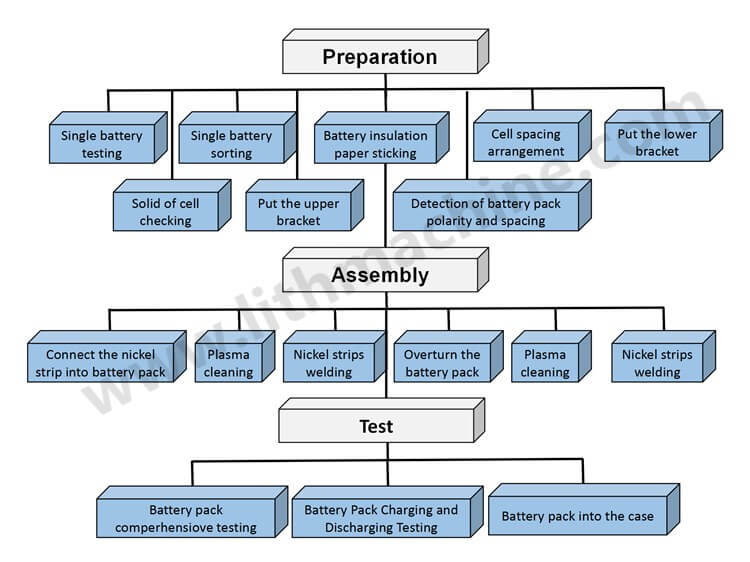

1. Cylindrical battery pack assembly line machine is suitable for all kinds of cylindrical battery pack makingaccording to customer's requirement.

2. Machine can be chosen according to customer's cell productivity.

3. Economic and high-efficiency.

Specifications

|

Process |

Type |

Product Name |

Product Link |

|

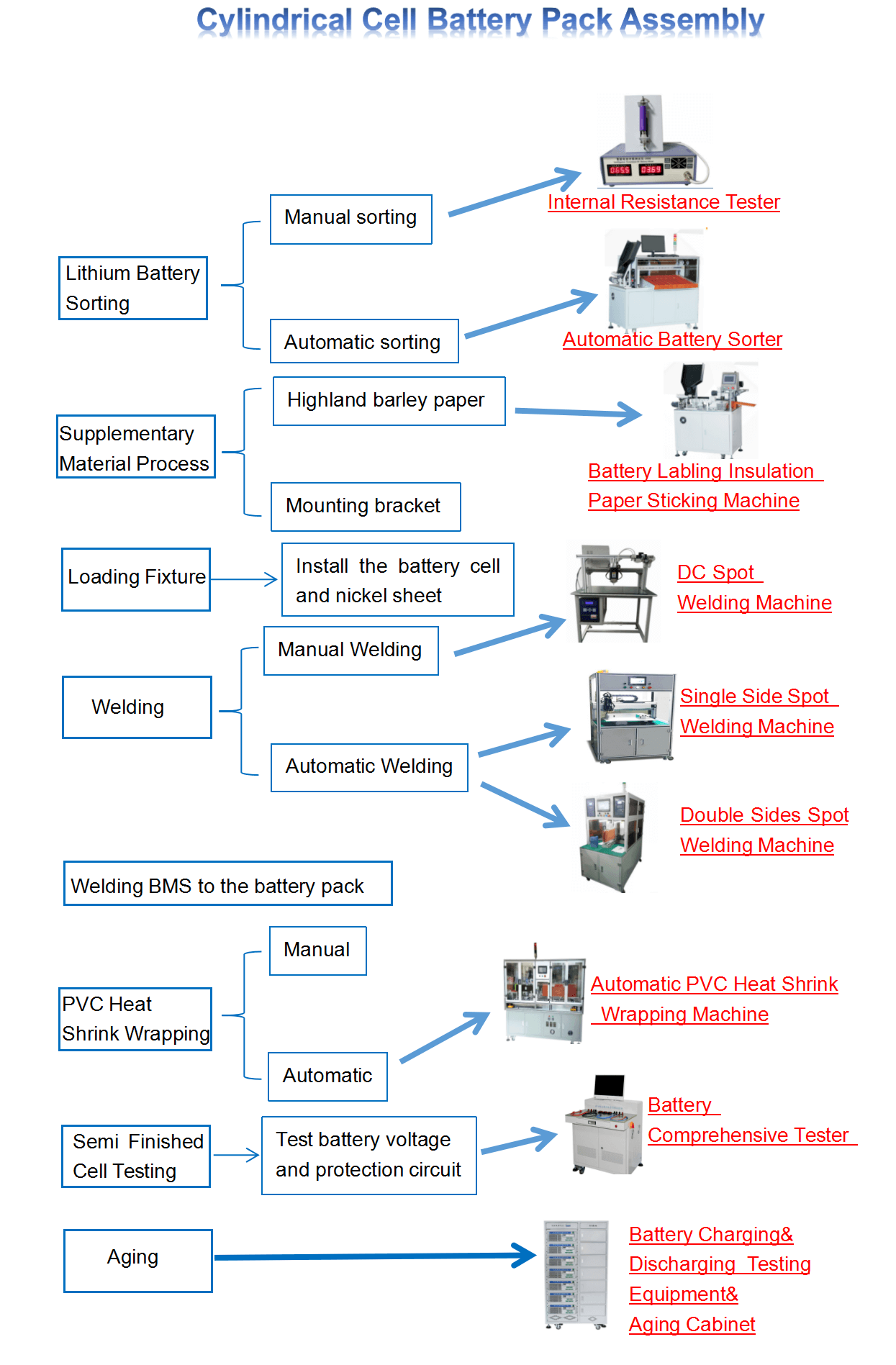

Lithium Battery Sorting |

Manual |

Internal Resistance Tester |

|

|

|

Automatic |

5/6/9/11/10/13/22 Channel Battery Sorter

|

|

|

Sticking Barley Paper |

Automatic |

Cylindrical Lithium Battery Labling Insulation Paper Sticking Machine

|

|

|

Spot Welding |

Manual |

1. AC Spot Welding Machine

2. DC Spot Welding Machine

3. Precise Micro Spot Welding Machine |

https://www.lithmachine.com/high-precision-dc-output-spot-welding-machine-tab-welder_p364.html

|

|

|

Automatic (Electric/Pneumatic) |

Single Side Spot Welding Machine

Single Side Rotary Head Spot Welding Machine

3. Double Sides Spot Welding Machine |

https://www.lithmachine.com/automatic-single-side-battery-spot-welding-machine-welder-for-18650-cylindrical-battery-pack_p363.html

|

|

PVC Heat Shrink Wrapping |

Automatic |

Heat Shrink Machine |

https://www.lithmachine.com/heat-shrink-machine-for-cylinder-battery-pack-assembly_p403.html |

|

|

|

Automatic 18650 PVC Heat Shrink Wrapping Machine For Cylindrical Battery |

|

|

Semi-finished Cell Testing |

|

Battery Comprehensive Tester |

|

|

Aging |

|

Battery Charging and Discharging Tester |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588