- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-HDP-3000MOQ :

1Color :

optionalPort :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 days

INTRODUCTION:

ADVANTAGE:

1. DC output. Heat concentration,the heat efficiency is increased, the welding process is stable, the welding quality is improved, and the electrode life is prolonged .

2. High speed and high precision microprocessor (MCU) control, to provide highly stable repetitive welding, with current monitoring function.

3. LCD display.

4. High speed welding: a quick start and high polarity switching reduced the temperature effect so that make the welding surface clean and beautiful.

5. Polarity switching: suppression of asymmetrical result makes the two points welding strength uniform and extends the service life of the electrode.

6. The imported IBGT module full control the discharge,welding quality and welding speed , non ordinary welding machine can compared with it.

7. Double pulse can reduce welding spatter, effectively improve the quality of welding.

8. Data storage using EEPROM, no battery life issues, always returned to the previous use of welding procedures when you starting up.

9. Welding voltage locking technology to prevent net voltage fluctuations to affect the welding current.

SPECIFICATION:

Model

LITH-HDP-3000

Transformer maximum output power

25KVA

Secondary side maximum welding current

6000A

DC energy storage capacity

6600uF

Welding pulse number

9 sets of pulses

Welding voltage

5v-330v adjustable, precision 0.5V

Welding time

0.1ms-5.0ms adjustable, precision 0.1ms

Welding mode

Normal / continuous

Input frequency

AC 220V±10% 50Hz±2Hz

Maximum working pressure

6KG

Weight

65KG

Weld thickness

Maximum thickness of parallel welding:0.03mm~0.3mm ,Multiple welding sheet

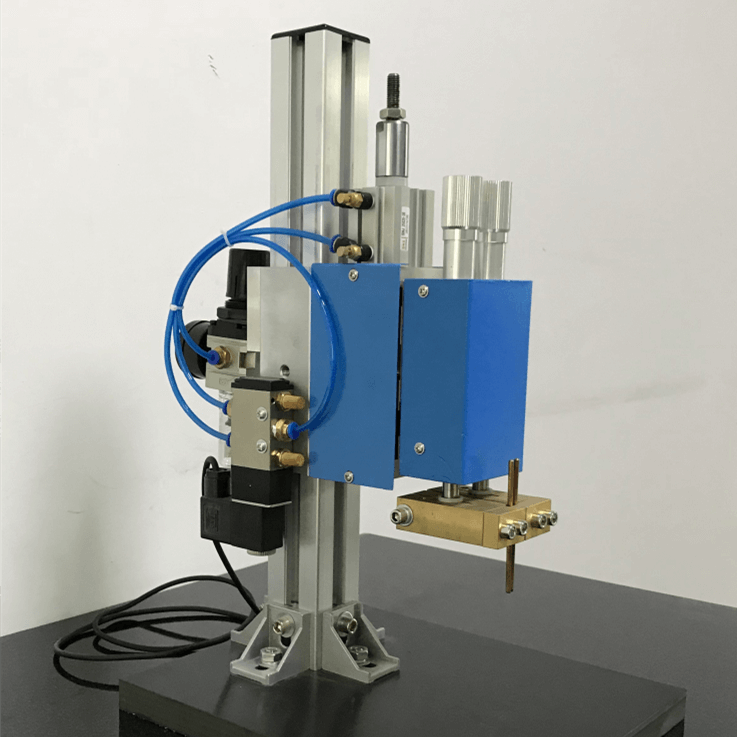

![]()

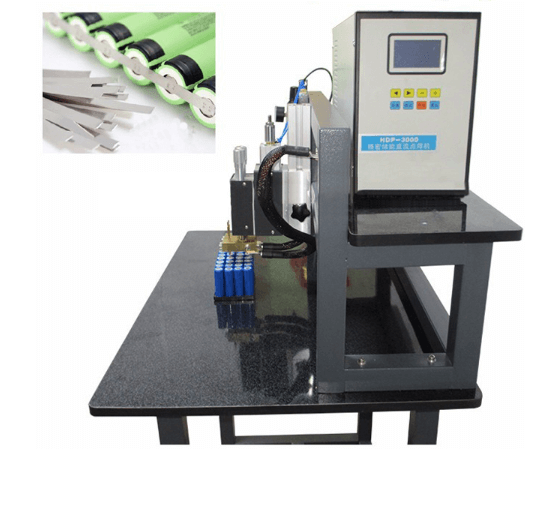

![]()

Related Machine

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588