- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-EWS/ETS/CHTMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

2 daysElectrolyte Wetting Testing System

Introduction

Combining the visual acquisition system and the capillary action of the electrolyte to evaluate the wetting differences of different electrodes, electrolytes, diaphragm formulations and processes.

Characteristic

1. Based on the principle of capillary diffusion of electrolyte in the electrodes and separators, quantitatively evaluate the difference in electrolyte infiltration;

2. Equipped with high-precision mechanical control and visual acquisition system, the test is stable and efficient;

3. Suitable for evaluation of infiltration differences of different electrodes, electrolytes, separator formulas and processes;

4. Characterize the infiltration rate of electrolyte in the sample in real time.

Applications

1. Electrolyte: Performance Evaluation

2. Electrode: Consistency Assessment

3. Optimization of material: Electrode Surface Treatment Processes

Description

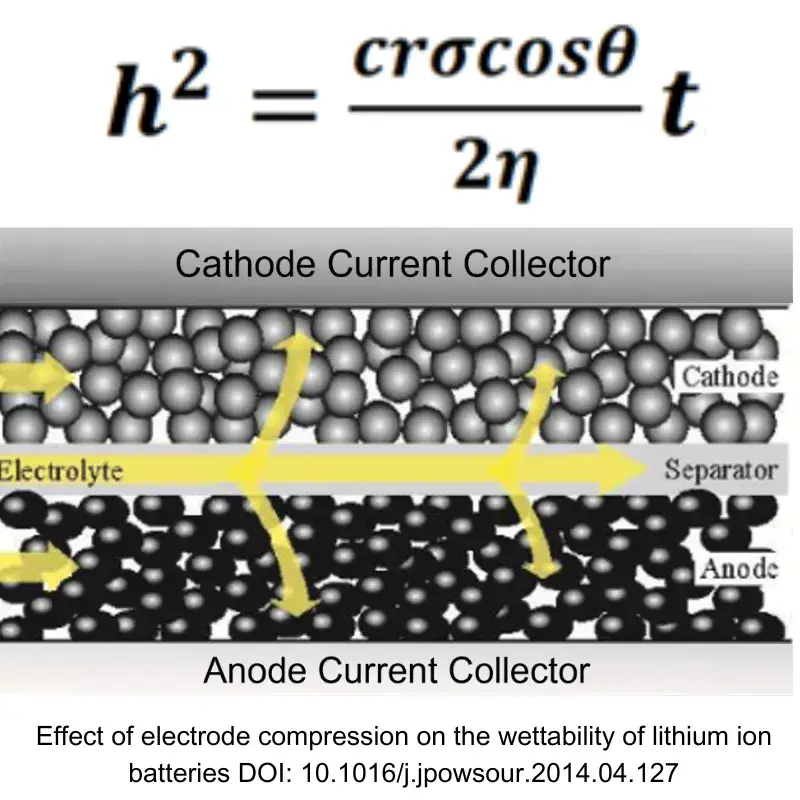

1. Principle of Electrode Wetting

The Lucas–Washburn Equation is commonly used to describe the dynamic of liquid absorption in electrode pores, as represented by the equation below:

1) r represents the radius of the capillary (m),

2) σ represents the surface tension of the imbibition fluid (N/m),

3) η represents the viscosity of the imbibition fluid (Pa*s),

4) θ represents the contact angle of the wet phase (°),

5) h represents the liquid suction height (m),

6) t represents the liquid suction time,

7) cr represents a fixed value, called the formal radius.

2. Applications

① Electrolyte: Performance Evaluation

② Electrode: Consistency Assessment

③ Optimization of material: Electrode Surface Treatment Processes

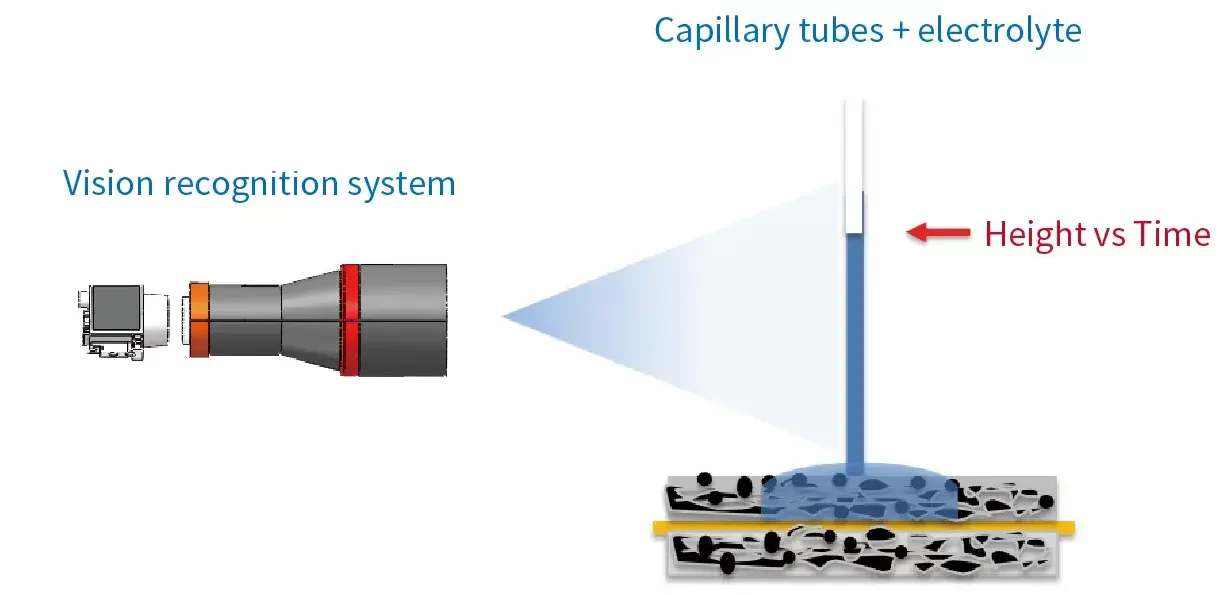

2.1 Capillary Wetting System-EWS Series

Key Features:

1) Equipped with a high-precision vision testing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rateon negative electrode sheets of lithium-ion batteries.

3) Applicable Samples: Negative electrode sheets.

4) The greater the compacticion of the electrode sheet, the lower the porosity, resulting in poorer electrolyte wetting.

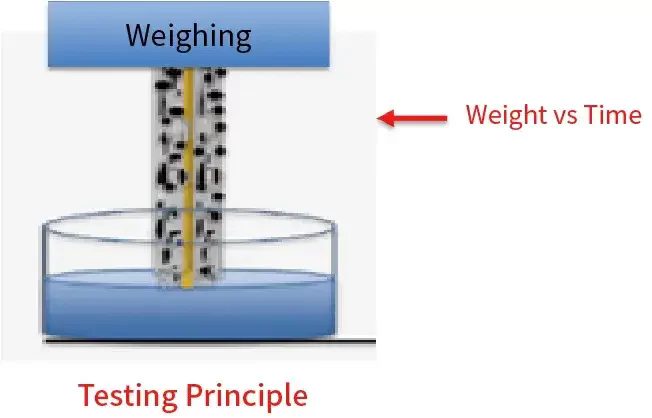

2.2 Weight Wetting System-ETS Series

Key Features:

1) Equipped with a high-precision weighing system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes & Jelly Cells

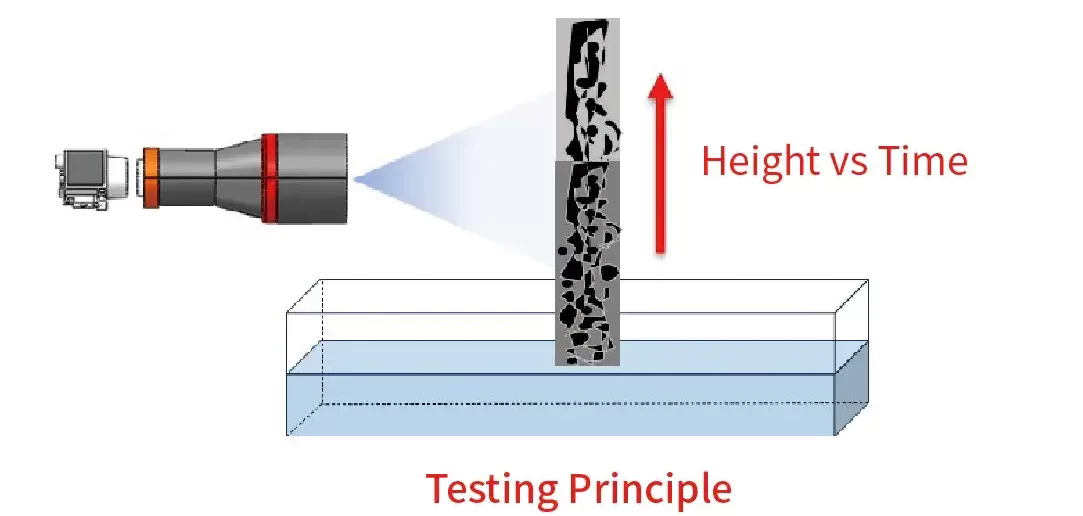

2.3. Height Wetting System-CHT Series

Key Features:

1) Equipped with a high-precision vision acquisition system for stable and efficient testing repeatability.

2) In-situ real-time characterization of electrolyte wetting rate on positive and negative electrode sheets of lithium-ion batteries.

3) Applicable samples: Anode electrodes

Application Cases

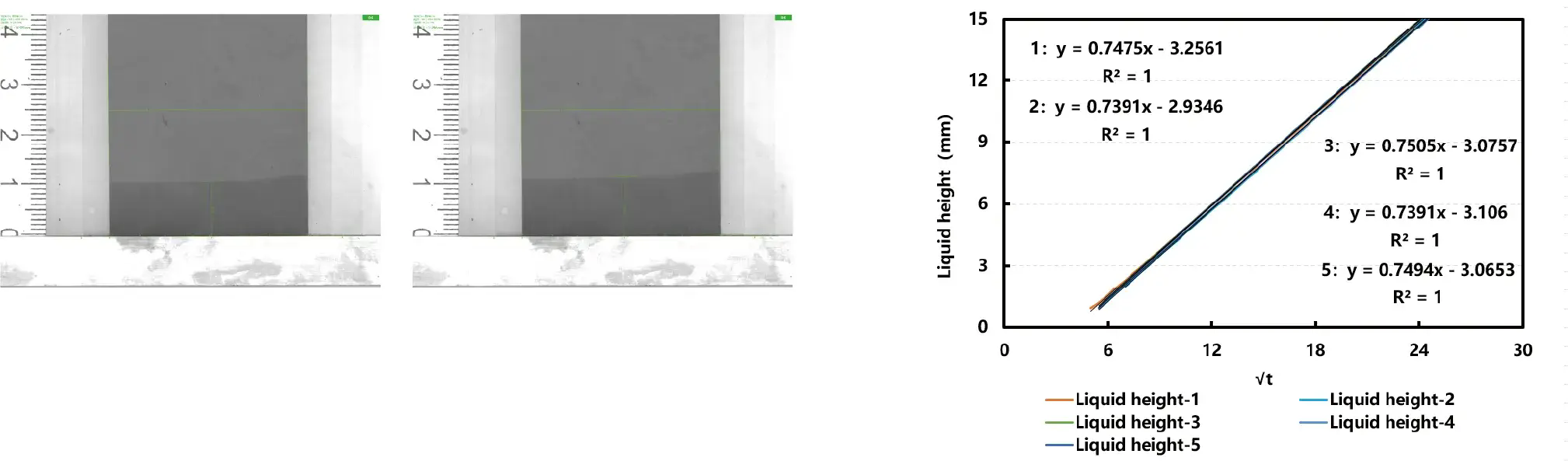

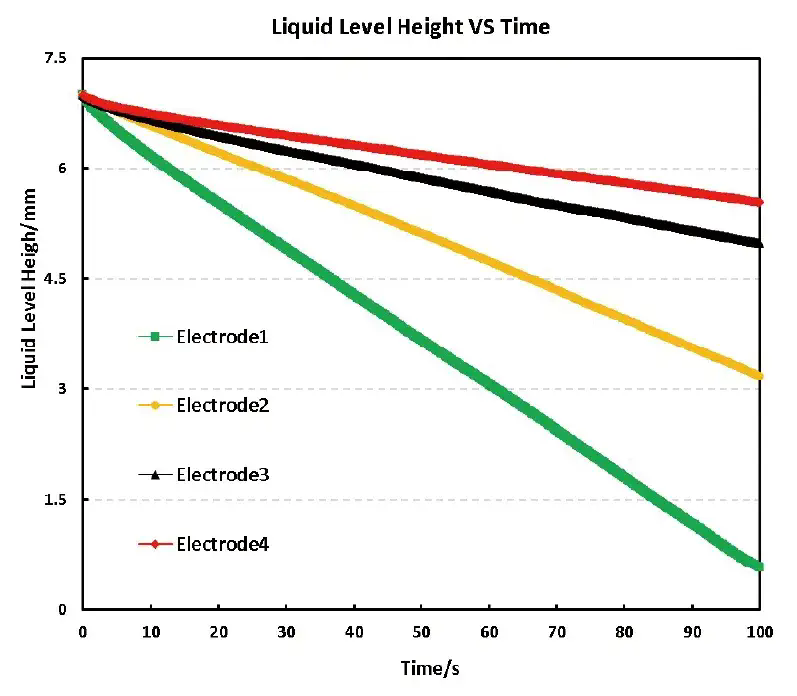

1. Capillary Wetting System-EWS Series

The greater the density of the electrode, the lower the porosity and the worse the electrolyte wettability.

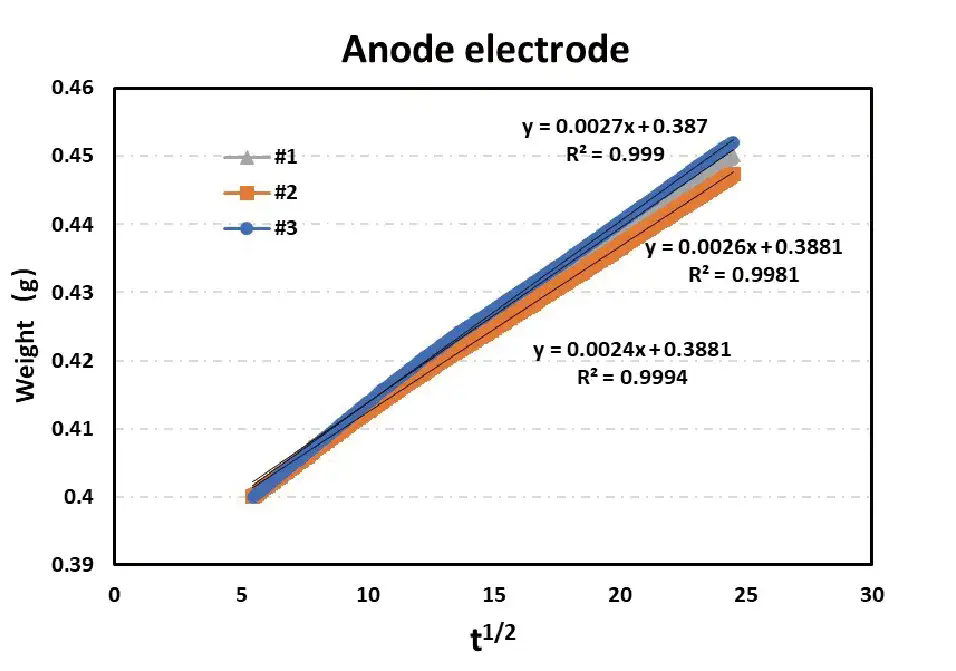

2. Weight Wetting System-ETS Series

Trimming three sets of negative electrode sheets from the same batch (65*70mm)

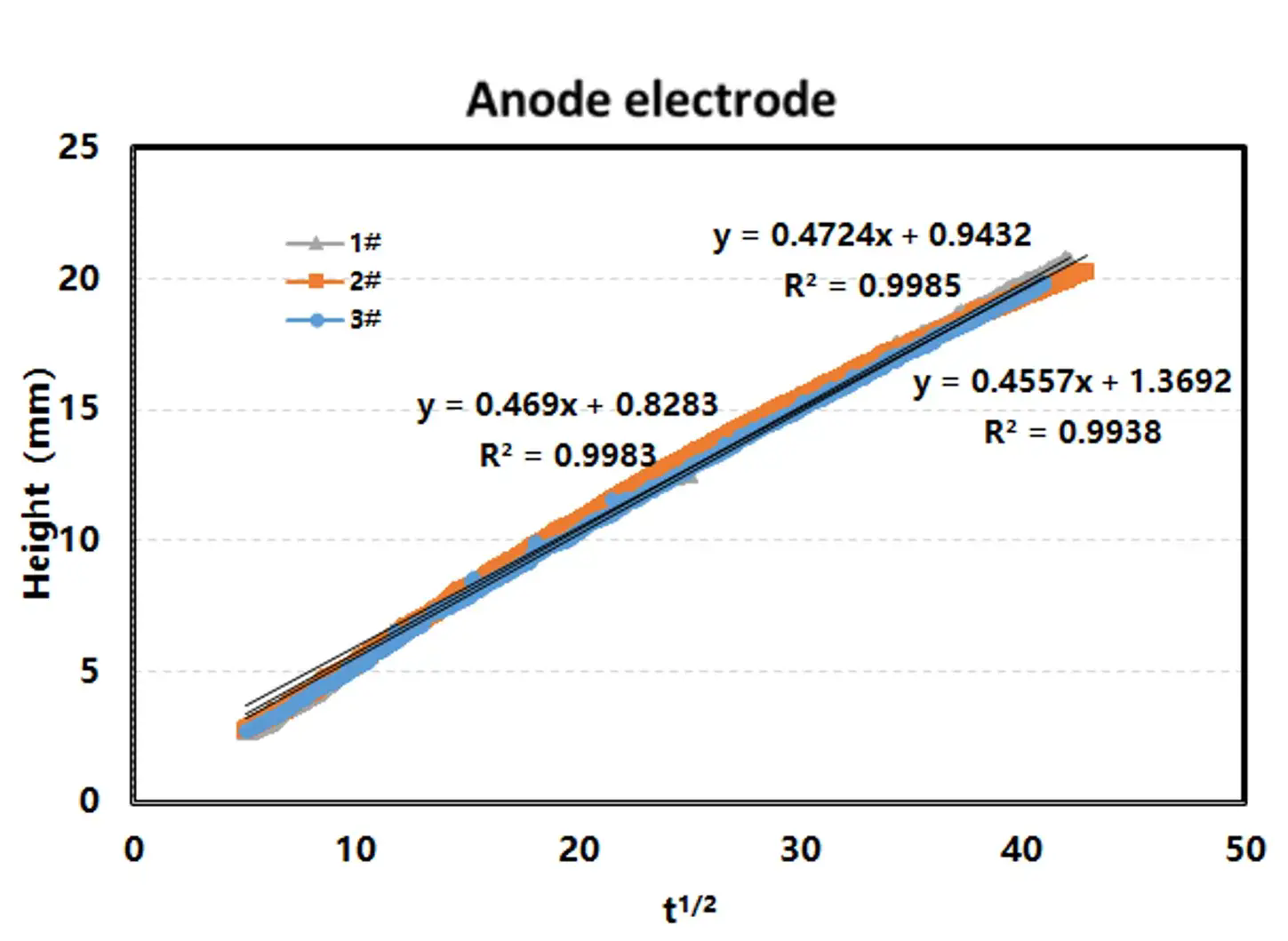

3. Height Wetting System-CHT Series

The slopes of the 3 tested electrodes are consistent with each other, so is the wetting consistency of their electrolytes.

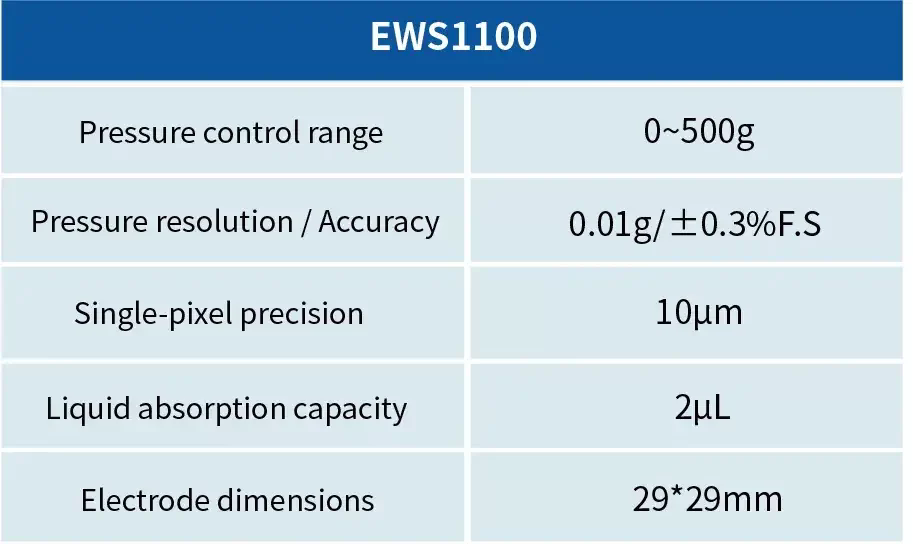

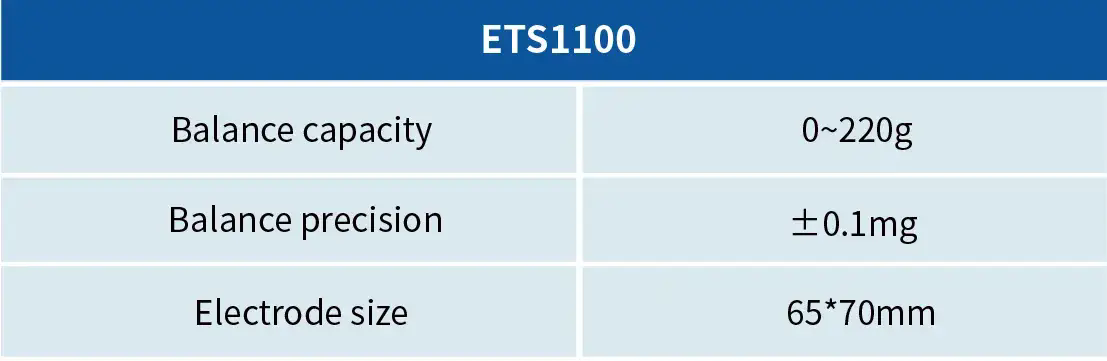

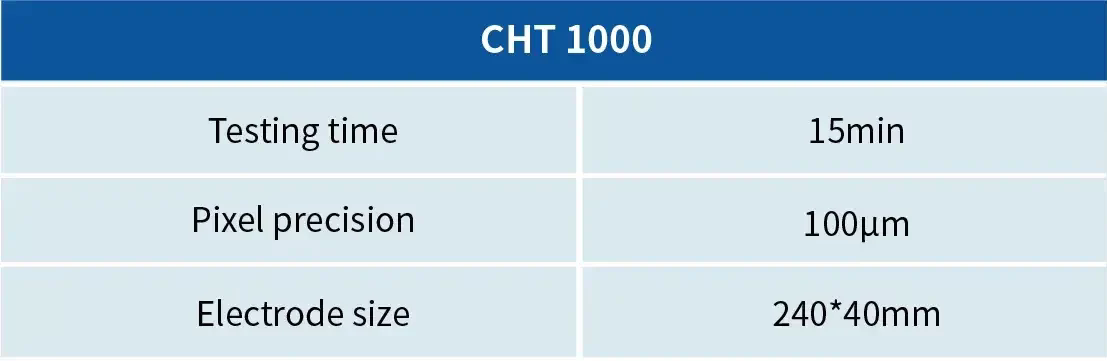

Specifications

Capillary Wetting System-EWS Series

Weight Wetting System-ETS Series

Height Wetting System-CHT Series

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME: 15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588