- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-KL3-20-70MOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

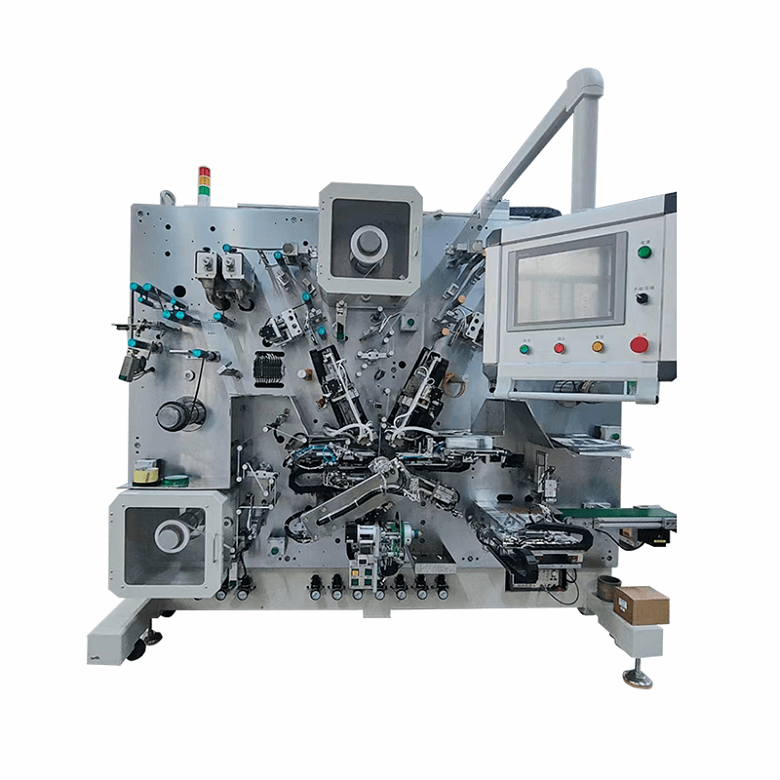

5 daysCylindrical Cell Fully Automatic Winding Machine

1. Equipment Description:

This device is used for producing cylindrical lithium-ion battery cells and is one of the key equipment in battery manufacturing. The process flow is as follows: the cathode and anode sheets prepared by the slitting machine, as well as the diaphragm, are actively unfolded, subjected to tension control, dust removal, coil guidance, ironing, diaphragm anti-static, quality inspection, and sent to the winding section through the guide roller and electrode feeding mechanism. After winding is completed, the battery is removed by the robotic arm, subjected to short circuit detection, counted by a photoelectric counter, and transported to the collection platform through a conveyor belt. If defective cells are detected during the processing, they will be rejected and sent to the defect collection box.

2. Incoming Material Requirements:

|

Item |

Specification |

|

Cathode and Anode Sheets |

|

|

Slitting Width Tolerance |

Within ±0.1 mm |

|

Coating Width Deviation |

Within 3% |

|

Waviness, Warping, Curling |

No edge waviness or curling; snake-like bending deviation < 0.3 mm/m |

|

Tab Connection |

Red or green tape for detection; single roll ejection |

|

Final Marking |

Remaining material on original roll must signal end; uncoated terminal > 1 m |

|

Separator Film |

|

|

Slitting Width Tolerance |

Within ±0.05 mm |

|

Waviness, Curling, Skirt Shape |

Visually screened |

|

Final Marking |

Green or black marking signals end of material |

3. Technical Specifications & Functions:

|

Category |

Parameter |

Value |

|

Applicable Material |

Electrode Width (excluding tabs) |

9–60 mm |

|

Tab Exposure Length |

8–25 mm |

|

|

Electrode Unit Length |

150–500 mm |

|

|

Electrode Unwinding Diameter |

φ400 mm |

|

|

Winding Needle Diameter |

1.8–6 mm (initial: 3 mm) |

|

|

Separator Unwinding Diameter |

φ300 mm |

|

|

Separator Width |

10–65 mm |

|

|

Winding Diameter |

φ6–20 mm |

|

|

Unwinding Core Inner Diameter |

φ76.2 mm |

|

|

Termination Tape Wraps |

0.5–1.5 turns |

|

|

Termination Tape Width |

20–50 mm |

|

|

Tape Roll Inner Diameter |

φ76.2 mm |

|

|

Winding Mode |

Tab Configuration |

One cathode & one anode tab |

|

Tab Insertion Order |

Anode-first or cathode-first, freely settable |

Function Description:

l Fault alarms, parameter & fault logs, operation history

l Lifecycle tracking with alerts, auto-stop

l USB export for production data

l Three-level password protection

l MES interface reserved

4. Equipment Structure Overview:

Electrode Feeding System (Cathode/Anode)

l Unwinding Stand: Single-arm, dual-support, servo-driven with auto-guiding and pneumatic expansion

l Tension Control: Potentiometer with swing arm; adjustable tension

l Dust Removal: Dual-brush + vacuum extraction system

l Web Guiding: Optical sensors and correction actuators

l Feeding Unit: Servo-driven, front/rear de-ironing

Separator Feeding System

l Same structure as electrode feeding

l Includes static elimination and web guiding

Winding Section

Three needle three station configuration

Pneumatic needle displacement

Servo driven rotation, angle/speed closed-loop adjustment

Scissor type electrode cutting with dust removal function

Pneumatic toothed blades for separators and tape cutting

Pneumatic robotic arm for cell unloading

Short circuit detection (DC 100-500V, 1-9 μ A)

Tape Feeding

l Passive unwind

l Cylinder-driven unrolling and pressing

l V-blade cutting

Cell Transfer System

l Intermittent belt conveyor, synchronized with machine cycle

l Separates good/defective cells

l Buffer zone ≥8 cells

Machine Frame

l Welded 50×100 steel structure, stress-relieved

l Double-sided ground wall panels

l Aluminum guide rollers, hard anodized, ≤30μm runout

l Left-side electric cabinet, separated zones for strong/weak current

l Fault display via touch screen & protected switches

l Alarm functions: material-end, break, short circuit, missing tabs, etc.

l Rejects defective cells automatically

l Cell counting and length measuring, alarms if ≥3 consecutive anomalies

l Equipped with safety guards

5. Equipment Technical Parameters:

|

Item |

Parameter |

|

Cutting Burrs |

Lateral: <30μm, Longitudinal: <15μm |

|

Alignment Accuracy |

Cathode/Anode: ≤±0.5 mm, Anode/Separator: ≤±0.5 mm |

|

Cell Diameter Tolerance |

≤±0.20 mm |

|

Pass Rate |

≥99.0% (non-equipment faults excluded) |

|

Uptime Rate |

≥95% (excluding non-equipment downtime) |

|

Productivity |

5–12 PPM (φ10, 250 mm electrode) |

|

Electrode Tension |

20 N adjustable (touch/manual) |

|

Separator Tension |

18 N adjustable (touch/manual) |

6. Installation & Commissioning Requirements:

|

Item |

Specification |

|

Air Source Pressure |

0.5 MPa |

|

Air Flow |

100 L/min |

|

Power Supply |

3-phase 380V, 50 Hz |

|

Power |

10 kW |

|

Weight |

2000 kg |

|

Ambient Temp |

-40°C to +45°C |

|

Humidity |

≤60% RH |

|

Dimensions |

2800 mm (L) × 1700 mm (H) × 1350 mm (W) |

|

Color |

Per customer request |

7. Major Component Specifications:

|

No. |

Name |

Brand |

Origin |

|

1 |

PLC |

INOVANCE |

— |

|

2 |

Detection Parts |

Omron/Keyence |

Japan |

|

3 |

Motor |

TUNGLEE |

Taiwan |

|

4 |

Servo Motor |

INOVANCE |

— |

|

5 |

Pneumatic Parts |

SMC |

Japan |

|

6 |

Bearings |

NSK |

Japan |

|

7 |

HMI |

WEINVIEW TK6102 |

— |

8. Spare Parts Supplied with Machine:

|

Name |

Specification |

Unit |

Qty |

Remarks |

|

Winding Needle |

3.0 |

Set |

2 |

3 included, 3 additional |

|

Separator Knife |

— |

Pc |

1 |

1 included, 1 additional |

|

Magnetic Sensor |

— |

Pc |

2 |

|

|

Toolbox |

— |

Pc |

1 |

|

|

Allen Wrench Set |

1.5–10 mm |

Set |

1 |

|

|

Phillips Screwdriver |

— |

Pc |

1 |

|

|

Long Nose Pliers |

— |

Pc |

1 |

|

|

Adjustable Wrench |

250 mm |

Pc |

1 |

|

|

Open Wrench |

5.5–7 mm |

Pc |

1 |

|

|

Open Wrench |

8–10 mm |

Pc |

1 |

|

|

Open Wrench |

12–14 mm |

Pc |

1 |

|

|

Open Wrench |

14–17 mm |

Pc |

1 |

|

|

Solenoid Valve |

4V-110-06 |

Pc |

1 |

|

|

Regulating Valve |

SCW-045 |

Pc |

2 |

|

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588