Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Microwave Oven – A Comprehensive Technical Introduction

A Microwave Oven is a widely used thermal-processing device engineered to heat, cook, dry, or sterilize materials through microwave electromagnetic energy. Unlike conventional heating methods that rely on thermal conduction or convection, a microwave oven utilizes volumetric heating, where microwave energy penetrates the material and generates heat internally. This makes the microwave oven highly efficient, clean, and suitable for modern households, laboratories, and industrial applications. With continuous advancements in control electronics, cavity design, and magnetron technology, the microwave oven has evolved into a reliable, precise, and energy-saving thermal equipment.

At the core of a microwave oven is the magnetron, a high-frequency vacuum tube that converts electrical energy into microwave radiation—typically at 2.45 GHz. When microwaves enter the stainless-steel cavity, they interact with polar molecules, especially water, causing them to oscillate rapidly. This molecular friction produces heat uniformly throughout the product. This mechanism not only accelerates heating but also significantly reduces energy loss compared with traditional external heating equipment.

The microwave cavity, often constructed from high-strength stainless steel with wave-tight sealing, ensures efficient microwave reflection and prevents leakage. A turntable or mode stirrer is integrated to distribute microwave energy evenly and eliminate hot spots, improving uniformity during heating. Many modern microwave ovens utilize intelligent power modulation, multi-frequency control, and sensor-based feedback to achieve fine temperature management and stable heating curves.

Modern microwave ovens typically include functional components such as an electronic control system, power supply module, waveguide, safety interlocks, exhaust ducts, and optional inverter power technology. Inverter microwave ovens allow continuous power adjustment rather than traditional on-off cycling, providing smoother heating, better food texture, and improved energy utilization. Some high-end units also integrate humidity sensors, infrared temperature measurement, and programmable cooking algorithms to ensure consistent and customizable performance.

From a structural perspective, a microwave oven is designed with rigorous electromagnetic shielding to ensure operational safety. Multi-layer metal screens and precisely engineered door seals prevent microwave radiation from escaping the chamber. Thermal insulation layers and efficient cooling systems help maintain stable internal temperatures and extend the lifespan of the magnetron and other components. Advanced models adopt brushless DC fans, low-noise drives, and high-efficiency air channels to enhance heat dissipation and reduce acoustic output.

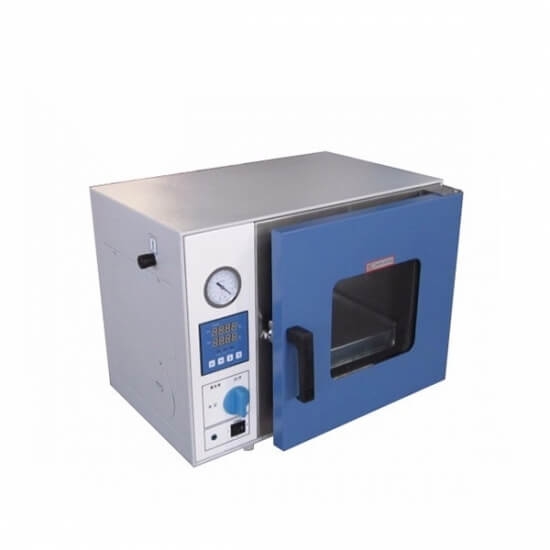

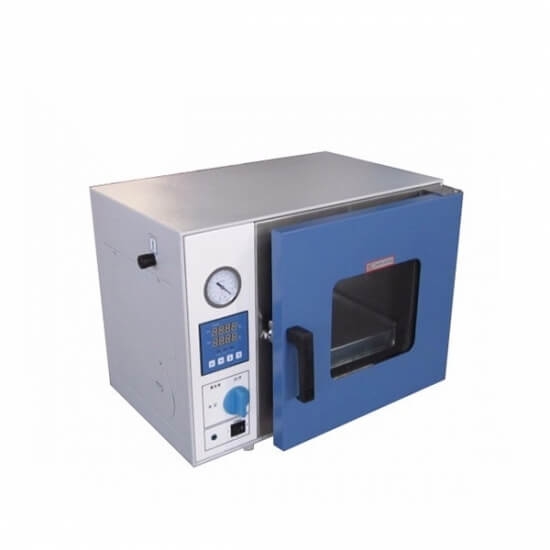

Microwave Vacuum Oven

In addition to domestic use, microwave ovens play an increasingly important role in scientific, industrial, and manufacturing environments. Laboratory microwave ovens are used for sample digestion, moisture content analysis, chemical reaction acceleration, and controlled material heating. These units feature enhanced temperature control, corrosion-resistant cavities, and programmable operation modes. Industrial microwave ovens support drying, curing, sterilization, and thermal processing for food, pharmaceuticals, and materials science. Their advantages include rapid processing speed, lower energy consumption, green operation with zero emissions, and high repeatability.

Safety is a critical aspect of microwave oven design. Modern systems incorporate multiple protective measures including door interlock switches, overheat protection, magnetron overload detection, and microwave leakage monitoring. The oven automatically cuts off power when the door is opened or when abnormal conditions are detected. These features ensure safe use in both domestic and professional environments.

In recent years, the microwave oven has evolved toward smart control, integrating IoT connectivity, touch-panel interfaces, voice operation, real-time cooking guidance, and cloud-based recipe management. This enhances user experience and allows precise process optimization. Furthermore, innovations such as steam-microwave hybrid heating, convection-microwave combination systems, and microwave grills expand the functional versatility of the equipment.

Overall, the Microwave Oven represents a mature, efficient, and intelligent heating technology. Its advantages—rapid thermal response, uniform energy distribution, compact design, and energy savings—make it an indispensable device across numerous fields. Whether in household kitchens, research laboratories, or industrial production lines, the microwave oven continues to offer reliable, clean, and high-performance thermal processing solutions.

English ▼

English ▼ English ▼

English ▼

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588