- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-KJ01H2MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Benchtop Dip Coating System Coater With Infrared Heating

Product Description

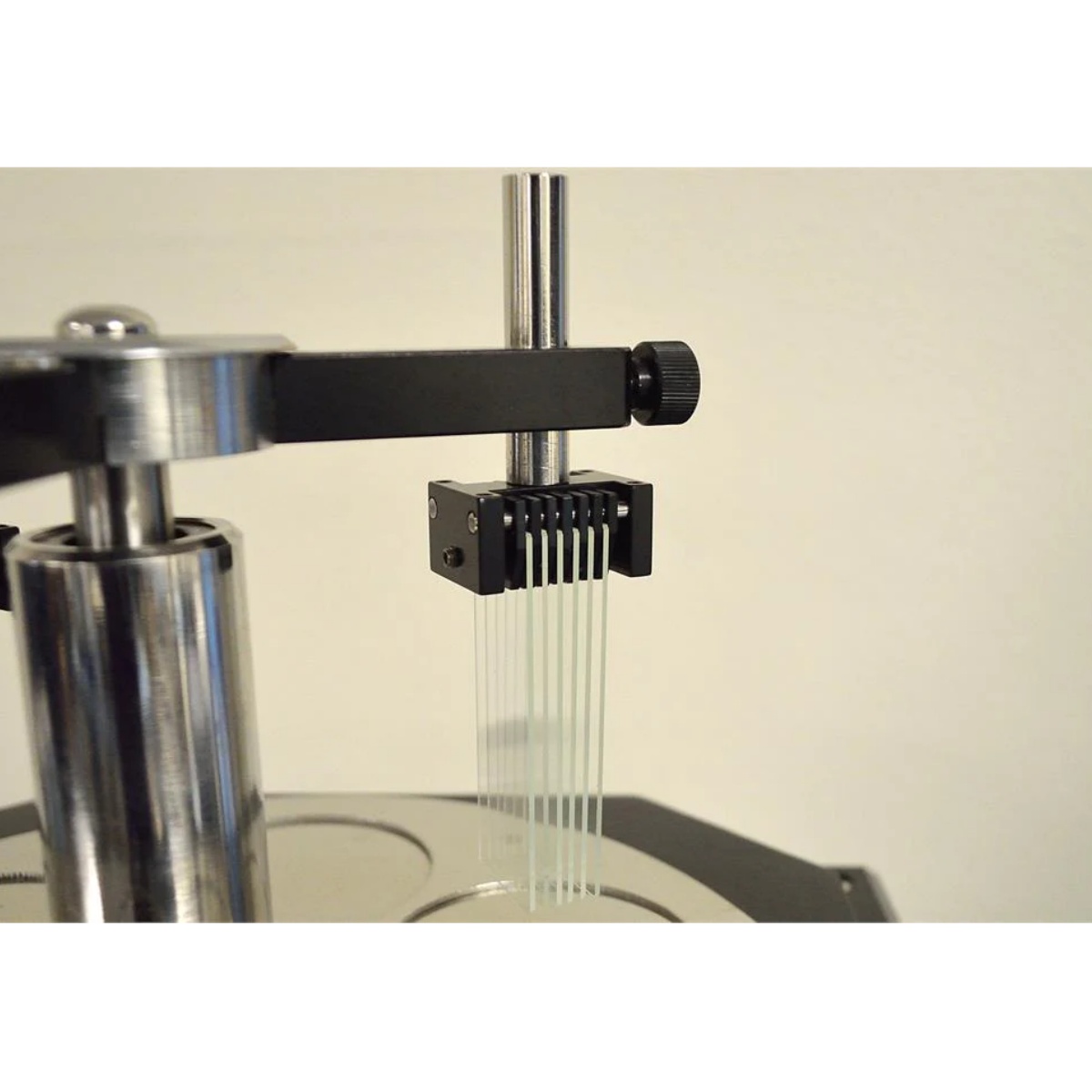

The LITH-KJ01H2 dip coating system with integrated infrared dryer minimizes operator involvement through microcontroller-controlled precision operation. A servo motor-driven linear stage ensures vibration-free and silent performance for uniform substrate coating.

Operation Modes

· Manual Mode: Front panel with LCD display and keypad for parameter input

· PC Mode: Full system control via included software with programmable memory

Key Features

· Infrared drying system (ambient to 200°C max)

· Dual operation modes (manual/PC control)

· Program memory for process storage

· Designed for physics, chemistry, and biotechnology applications

Technical Specifications

|

Category |

Specification |

|

Model Number |

LITH-KJ01H2 |

|

Actuator |

Servo motor |

|

Drive Mechanism |

Lead screw |

|

Coating Speed Range |

2-9000 μm/s |

|

Power Requirements |

208-240VAC, 50/60Hz |

|

Max Power Draw |

600W (with heater) |

|

Max Stroke Length |

150mm |

|

Max Substrate Size |

40×50mm |

|

Temperature Control |

PID digital controller (±1°C accuracy up to 200°C) |

|

Control Interface |

LCD display with 5-program memory |

|

Data Port |

RS232 for PC connection |

|

Certification |

CE Certified |

Standard Configuration

· Dual substrate holder

· Operation software included

Optional Accessories

· Multi-sample holder (additional cost)

Application Guidelines

· Plasma cleaning recommended for optimal coating quality

· Coating thickness calculable via Landau-Levich equation:

h = coating thickness, η = viscosity, γLV = liquid-vapor surface tension,

ρ = density, g = gravity

· Ultrasonic dispersion recommended for nanomaterial solutions

· Compatible with gloveboxes for controlled atmosphere operation

· Suitable for cleanroom use with bench-top fume hood (carbon-filtered)

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588