- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-DYG-110BH-950MOQ :

1Compliance:

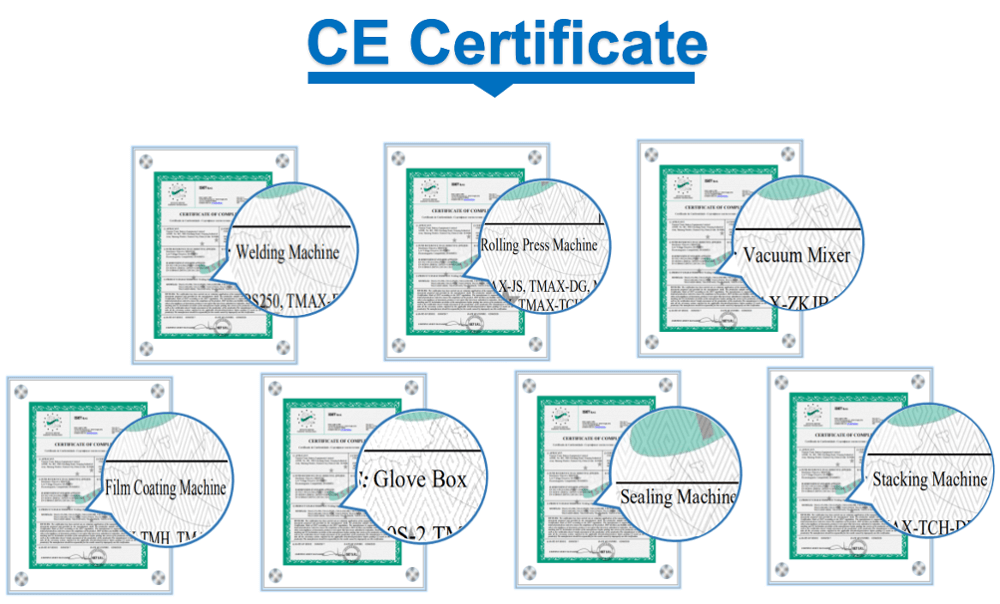

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

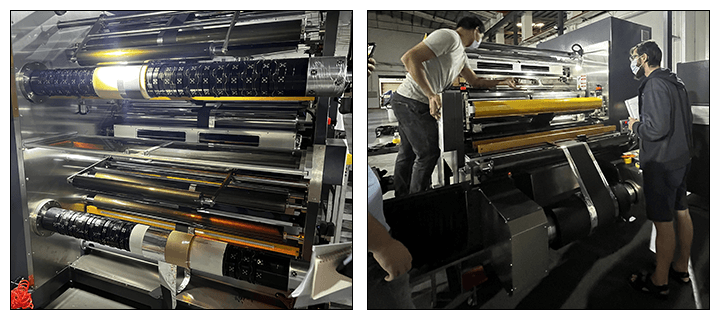

Automatic Roll To Roll Slitting Machine for Battery Electrode Preparation

A. Equipment functions:

This set of equipment is a segment slitting line made of lithium-ion battery, which is applicable to the continuous slitting process. This set of equipment is mainly composed of passive unwinding part, unwinding deviation correction part, powder brushing and dust collection part, tension buffer part, slitting part and automatic upper and lower winding part.

1) The cutting device adopts Xicun type cutting structure, and the upper and lower cutter shafts are driven by servo motors respectively;

2) The slitting head adopts one key positioning function, which makes loading and unloading of the head convenient and fast;

3) The connection between the upper and lower cutter shaft motor drive and the machine head adopts soft connection, so as to prevent the machine head from shaking due to processing or assembly errors during rapid cutting, thus affecting the cutting quality and effect;

4) The utility model has a pole piece belt connecting platform, and a dust collecting box and a negative pressure interface are arranged under the chute to facilitate the connection with the industrial dust collector;

5) It has the function of dust and iron removal by pole brush; Dust and iron removal are also designed after slitting;

6) Slitting speed: mechanical design speed 60m/min; Actual production speed 50m/min;

7) With PLC control constant tension winding;

8) The taper top type jacking sleeve is used for unwinding, and the unwinding is carried out passively; Winder adopts slip air expansion shaft;

9) The tool rack adopts a push-out movable tool rest, which is equipped with an organic carriage for convenient tool change;

10) The upper knife can be fine tuned, and the fitting with the lower knife can realize gapless shearing,;

11) Tension control in the whole process from unwinding, slicing and rewinding;

12) There is a ruler for winding and unwinding, which is convenient for material adjustment;

13) The speed adopts the servo motor control system for stepless speed change, and realizes the synchronization of all components;

14) The cutter head is pushed in and out as a whole, and each machine is equipped with a quick change car for the cutter head;

A. Applicable material conditions:

(Unit:mm)

|

Unwinding diameter: |

max Φ600㎜ |

|

Unwinding weight: |

Max:800kg |

|

Inner diameter of unwinding drum: |

Φ6” |

|

Width of foil |

Max850mm |

|

Foil thickness |

Copper foil: 6-20 μ m; Aluminum foil: 9-20 μ m |

|

Width of coiled material: |

Maximum coating width of cutting material: max850mm |

|

Thickness of slitting pole piece: |

50~300 μ m |

|

Winding diameter: |

Max: Φ 500㎜ |

|

Winding weight: |

Max:400kg (single axle) |

|

Inner diameter of winding drum: |

Φ 6 "< reel prepared by user > |

A. Installation requirements for whole line equipment :

1) Power requirements: 380v/50hz, power about 12KW;

2) Compressed air: pressure 0.5mpa~0.7mpa, flow: 0.015m3/min;

3) Total weight of equipment: About 5T, and the load-bearing requirement of installation ground is >2.5t/m2.

4) Overall dimension of connecting equipment (mm): overall dimension of the whole machine (length × wide × Height): about 2600mm long × 2200mm wide × Height 2000mm

Overall dimension of tool carriage (length * width * height): about 1800mm*400mm*500mm

B. Equipment performance index:

|

No. |

Entry name |

Performance index |

Remarks |

|

1 |

Production speed of complete equipment |

≥50m/min |

Acceptance speed |

|

2 |

Deviation correction accuracy requirements |

±0.2mm |

|

|

3 |

Stroke range of deviation correction controller |

±50mm |

|

|

4 |

Precision of slitting width |

≤±0.05mm |

|

|

5 |

Serpentine bending error of pole piece |

≤1mm/1m |

|

|

6 |

Blade specification |

Upper knife Φ130*Φ88*1mm、down knifeΦ130*Φ70*3mm |

|

|

7 |

Slitting burr accuracy |

Transverse burr≤12μm;Longitudinal burr≤8μm |

|

|

8 |

Single service life of blade |

≥200000 meters |

|

|

9 |

Qualification rate of products produced by equipment |

≥99% |

|

|

10 |

Time rate |

>98% |

|

C. Configuration of main equipment components:

|

No. |

Name |

brand |

|

1. |

Wallboard rack material |

45# cast steel |

|

2. |

Roller bearing |

NSK |

|

3. |

Reducer motor |

Dongli, Wanxin |

|

4. |

PLC |

Mitsubishi, Omron |

|

5. |

Touch screen |

Proface, Kunlun state |

|

6. |

Servo motor |

Mitsubishi, Huichuan |

|

7. |

Linear guide rail |

HIWIN |

|

8. |

Slitter shaft bearing |

SKF、NSK |

|

9. |

Solenoid valve |

SMC、CKD |

|

10. |

Electrical components |

Schneider、ABB |

|

11. |

Electric proportional valve |

SMC、CKD |

|

12. |

Deviation correction control System |

Pausource、Dongdeng |

|

13. |

Frequency converter |

Mitsubishi, Schneider |

|

14. |

Tension controller |

kortis |

|

15. |

Sensor |

Omron、KEYENCE |

|

16. |

Pneumatic components |

SMC、CKD |

|

17. |

Slitting tool |

Orin |

D. Equipment matching:

Pole slice slitting is mainly composed of unwinding device, deviation correction device, belt connecting platform, tension buffer part, pole slice traction device, slitting device, dust and iron removal device, winding part, electrical control system, etc.

1)Unwinding device:

The device is used to support the coil material to be cut and transport it to the cutting machine head for cutting. The device consists of a frame, a deviation correction device, a cone top mechanism, a brake for passive unwinding, belt connection for dust and iron removal, a tension controller, a roller, etc; Unwinding is manual rewinding.

|

No. |

Function name |

Performance index and description |

Remarks |

|

1 |

Unwinding mechanism |

Passive unwinding |

Unwinding direction: it can support clockwise / counterclockwise free switching |

|

2 |

Coil fixing method |

Adopt cone top chuck and fix it by pneumatic jacking; |

|

|

3 |

Sleeve size |

6 inches |

The length of sleeve is adjustable within 900-1000mm |

|

4 |

Pole piece tension control |

Tension 30-400n, control accuracy: ± 5N |

|

|

5 |

Pole piece position detection device |

Ultrasonic position sensor (sensor accuracy: ± 0.1mm) |

|

|

6 |

Deviation correction control |

Detection accuracy: ± 0.1mm |

|

|

7 |

Implementation scope of deviation correction |

≥±50mm |

|

|

8 |

Deviation correction accuracy |

≤±0.2mm |

|

|

9 |

Incoming coil diameter |

Max:φ600mm |

|

|

10 |

Incoming coil weight |

Max:800Kg |

|

2)Tape receiving platform (manual tape receiving):

It is used to manually fix the pole piece on the belt connecting platform during the pole piece slitting process or during coil changing, and connect the pole piece with adhesive tape. Designed at the position of the unwinding mechanism. It is mainly composed of two passing rollers, four air cylinders, two pressure bars and the receiving platform. Manual operation: first press the pole piece, then cut the pole piece along the groove on the receiving platform with a blade, then loosen the pressure bar at the end that needs to be newly connected to the pole piece, replace it with a new pole piece, align it with the original marking beginning of the pole piece, paste adhesive tape, and continue production after loosening the two pressure bars.

|

No. |

Function name |

Performance index and description |

Remarks |

|

1 |

Belt connecting platform |

It is composed of connecting plate, double pressure bar, 4 air cylinders and guide rail, and is integrated with the unwinder device |

Cylinder driven pressing plate (adhesive strips are pasted at the contact between pressing plate and pole piece) |

|

2 |

Tape connection mode |

Manual tape splicing |

The pole piece shall be manually fixed on the tape receiving platform when the tape is broken or the coil is changed, and the pole piece shall be bonded with adhesive tape |

|

3 |

Width of strip electrode |

Max850mm |

Including edge foil |

3)Tension part:

The tension sensor is used to detect the tension of the pole piece, and the stability of the tension of the pole piece is ensured by the tension adjusting device;

Tension adjustment range: 30 ~ 400N;

Tension control accuracy: ≤± 5N.

4)Slitting device

The slitting device adopts Xicun type slitting structure. The upper and lower slitting cutter shafts are driven by servo motors respectively to slit the rolled pole pieces.

The slitting device adopts one key positioning function, which makes it convenient to load and unload the machine head. The connection between the motor drive and the machine head adopts soft connection, so as to prevent the machine head from shaking due to processing or assembly errors during rapid slitting, thus affecting the slitting quality and effect. The slitting width adopts high-precision bushing to match the size to be slitted.

The traction mechanism is driven by a servo motor. The linear speed of the traction roller and the cutter is synchronized. The rubber roller is pressed by the air cylinders at both ends on the driving roller to realize the compression of the material, and the synchronous control of the pole tension and speed is fully realized.

The machine head adopts Xicun tool rest mode, the upper and lower tool shafts are driven separately by servo motors, and the upper blade can be spiral adjusted. The upper blade adopts a sharp blade and the lower blade adopts a flat blade; The width of the spacer sleeve can be changed to achieve the slitting size. The tool rest is equipped with a hydraulic cart to facilitate the replacement of the tool rest

Two groups of roller brushes are used to clean the slitted pole pieces respectively, and the dust removal cover and pipeline interface are equipped to facilitate the dust collection of customers. Equipped with industrial vacuum cleaner.

|

No. |

Function name |

Performance index and description |

Remarks |

|

1 |

Upper cutter mode |

West Village structure |

|

|

2 |

Slitting speed |

≥50m/min |

|

|

7 |

Minimum slitting width |

≥30mm |

Width of single slice after slitting |

|

8 |

Precision of slitting width |

≤±0.05mm |

|

|

9 |

Serpentine bending error of pole piece |

≤1mm/1m |

|

|

10 |

Blade specification |

Upper knife Φ130* Φ 88*1mm, down knife Φ 130* Φ 70*3mm |

|

|

11 |

Slitting burr |

Transverse burr ≤ 12um; Longitudinal burr ≤ 8um |

|

|

12 |

Service life of Slitter |

≥ 200000 m (positive pole), ≥ 300000 m (negative pole) |

|

|

13 |

Grindable times |

About 5 times |

|

|

14 |

Tool change trolley |

2 sets |

Each machine head is equipped with a tool change trolley |

|

15 |

Number of slitting heads |

2sets |

One for standby and one for use |

|

16 |

Time for changing the slitter |

≤10min |

|

|

17 |

Slitting process (slitting quantity) |

According to customer process requirements |

Configure according to the contract quantity |

|

18 |

Number of knives |

According to customer process requirements |

Configure according to the contract quantity |

|

19 |

Cutter shaft |

Circular runout ≤ 8um |

Installation on equipment inspection |

|

20 |

Circular runout of upper blade |

Axial runout ≤ 30 um. Radial runout ≤ 30um |

Installation on equipment inspection |

|

21 |

Circular runout of lower blade |

Axial runout ≤ 20um. Radial runout ≤ 20um |

Installation on equipment inspection |

|

22 |

Over roll |

Circular runout ≤ 20um |

Installation on equipment inspection |

|

23 |

Driving roll |

Circular runout ≤ 5um |

|

|

24 |

Roll installation accuracy |

Parallelism between rolls 5um; Roll levelness 50um/m |

|

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588