- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-DS-01MOQ :

1Color :

optionalPort :

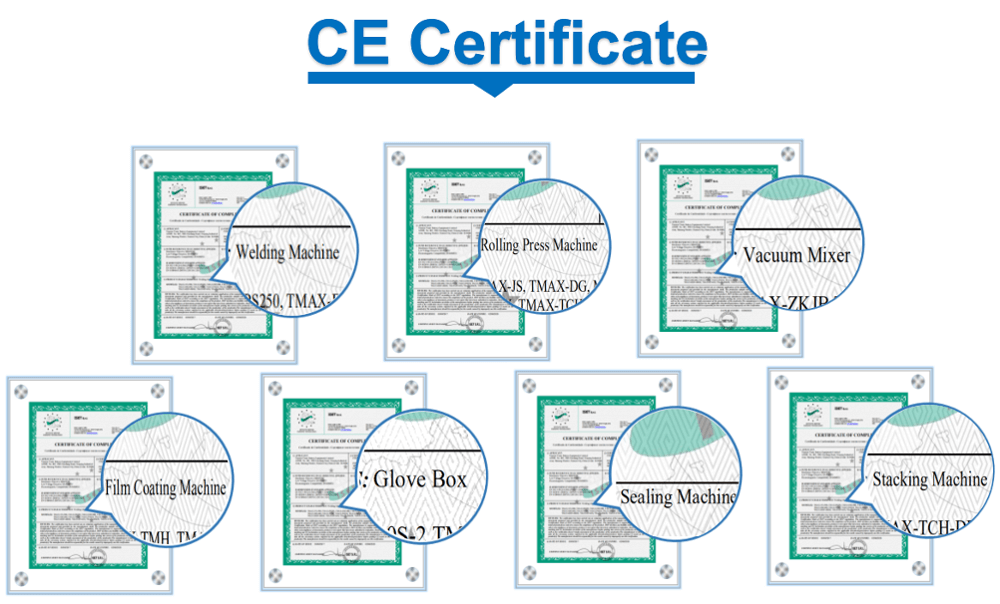

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 days

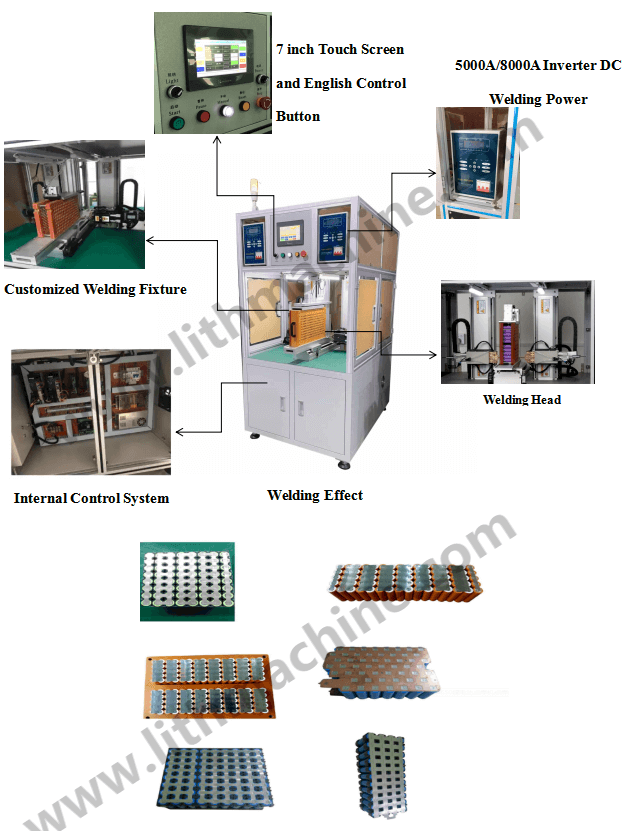

Product Application

The Automatic Battery Pack Spot Welder is a general platform of automatic processing technology based on CNC, suitable battery pack spot welding and assembly in the factory. Compared with manual spot welding, the efficiency and accuracy of welding have been greatly improved. Humanized design makes the operation and debugging very easy and convenient. Design of components built-in makes appearance more concise.

Advantages

1) Induce load voltage, control voltage by feedback, and realize high quality welding.

2) Preheat, Main Heat's power mode, preheating before welding, to ensure stable welding quality.

3) Keep the continuity of energy density, shorten the welding time, and reduce the deformation and color of base metal. (Welding time controlled in microseconds, continuous output mode)

4) Easy to change from low current to high current, suitable for precision welding.

5) The upper and lower limits of current can be set to simply judge whether the welding quality is good or not, which is suitable for welding automation platform.

6) The welding current rises with the time of electrification to ensure the welding effect.

Features

1. Support breakpoint start, automatic start, and manual start.

2. Cold solder joint and sealing off alarm.

3. Easy program, support matrix, array and point program, can store 99 group parameters.

4. Welding needle abrasion alarm.

5. Build-in welding current monitor, can display real time welding current.

6. Design for NB, Power Tool, Gardening Tool, High Power, Energy Storage battery, Electric Motor Car Battery Pack, and other lithium battery packs spot welding.

7. High productivity: 0.35s/spot

8. Can be matched with the production line of lithium battery group.

9. Automatic battery pack spot welder adopts traditional pneumatic single point dynamic, ensure the welding accuracy, and improve the welding appearance quality and reliability.

10. Can store dozens process of different battery packs product, switching products without re-setting parameters.

11. Can match a variety brand of spot welders.

Application Area

With the corresponding fixture, the spot welding machine can weld 18650, 26650, 32650 and other cylindrical batteries, can also be customized for a variety of cylindrical battery, square battery, button battery and etc.

Operation

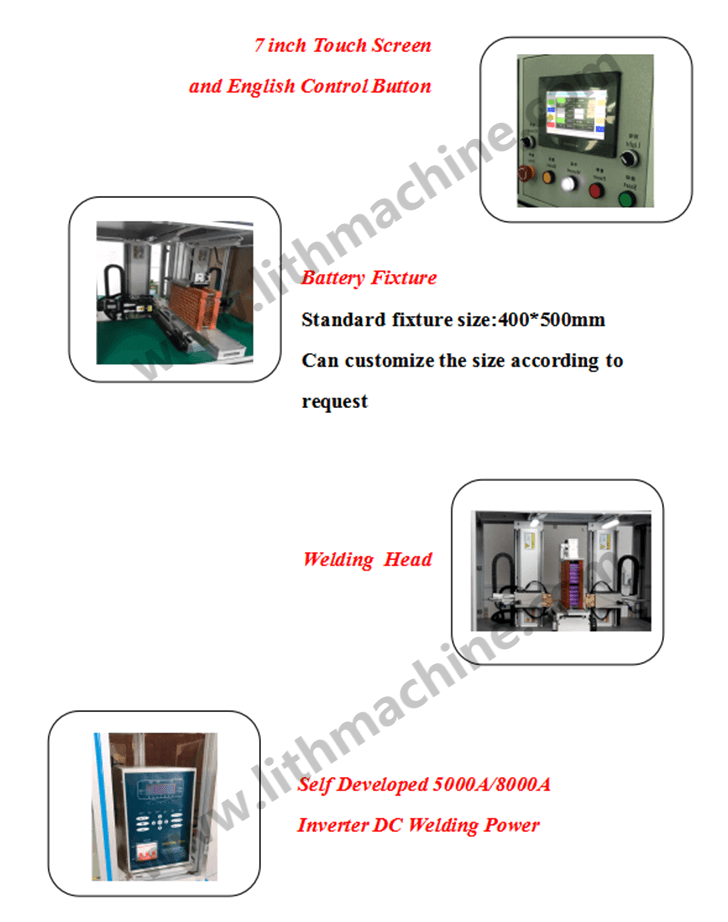

1. Setting the parameters of welding on the touch screen. (The same product only need to be set once)

2. Put the fixture with the battery pack on the quick clamping position.

3. Press the start button, the machine automatically complete all welding actions.

4. The welder sound to prompt operator replacement of new fixture (battery pack).

Specifications

Welding Head Number

2

Welding Head Types

Rotary Welding Head

Rotation Function of Welding Head

The welding head supports positive and negative rotation, and is suitable for spot welding of special-shaped batteries and anti-sticking needle function.

Rotary Welding Head

R:180º

The distance between tooling platform and welding needle can be adjusted by 300 mm.

Travel

Y: 500mm; Z; Z2:350mm

Welding Speed

0.35s/spot,3600pcs/h

Welder Power Suppler

5000/8000A Inverter Spot Welder

Max Motor Speed

1000mm/s

Max Battery Number

200-600 pcs cells

User Interface

Touch screen

Driving Mode

Step motor and precision guide rail

Power Supply

220V/50Hz(machine); 3 phase, 380V/50Hz(Welder)

Air Pressure

0.4-0.7 MPa

Machine Size

900L*1200W*1600Hmm

Machine Weight

350kg

Repeated Positioning Accuracy

±0.02mm

Number of Loaded Cores

Y: 26 pcs

Z: 18 pcs (adjustable)

Welding Material

Pure nickel sheet: 0.03-0.2mm

Nickel-plated steel strip :0.03-0.3mm

Number of storable file groups

99

Operating system

Embedded system + man machine interface

|

Key component name |

Brand |

|

Screw |

TBI (Taiwan) |

|

Guide |

Shangyin / Jieyin (Taiwan) |

|

Spot control system |

Tmax automatic spot welder special embedded system |

|

Touch screen |

EASYVIEW(Taiwan) |

|

Servo motor |

WIZCOM (Janpan) |

|

Stepper motor |

BECKHOFF(China) |

|

Power supply |

MEANWELL (Taiwan) |

|

Solenoid valve |

AirTAC(Taiwan) |

|

Cylinder |

AirTAC(Taiwan) |

|

Photoelectric sensor |

Omron / Panasonic(Janpan) |

|

Welding machine power supply |

High frequency DC welding power supply |

|

Welding Head |

(independent research and development) |

![]()

Related Machine

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588