ItemNo :

LITH-CY5V6A-16WMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

5V 6A 16 Channel Hot Press Formation Machine for Pouch Cell

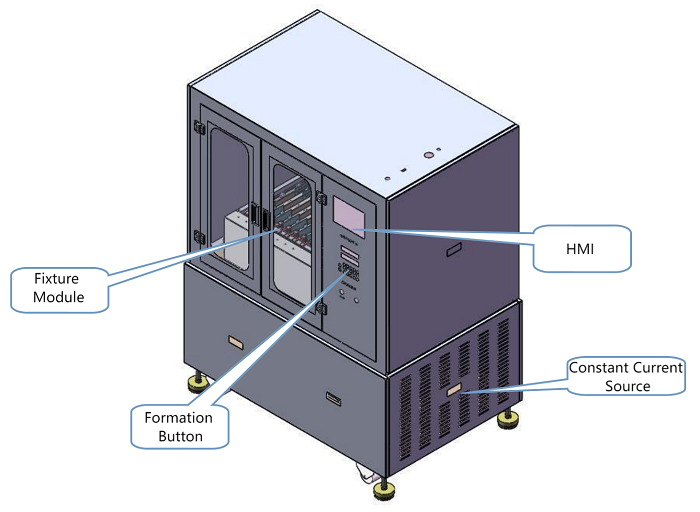

The equipment is composed of six major systems: temperature control, over/under-temperature alarm, over/under-voltage alarm, pressure control, formation cabinet system, and fixture mechanism.

It features: Independent temperature control for each board layer, pressure control, charge/discharge functions, overcharge/discharge protection, reliable contact between battery tabs and contact points, data connectivity, data storage upon process completion, voltage sorting after charging, capacity sorting after discharging, and smoke alarm system.

3. Equipment Structure

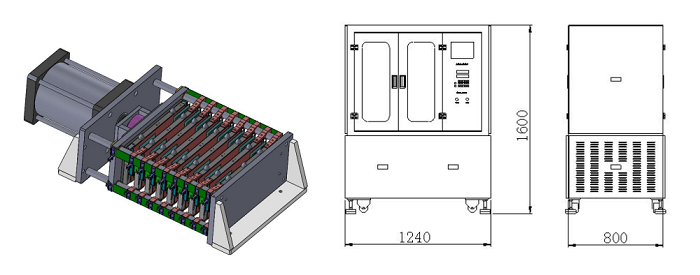

4. Fixture Structure and Overall Dimensions (for reference)

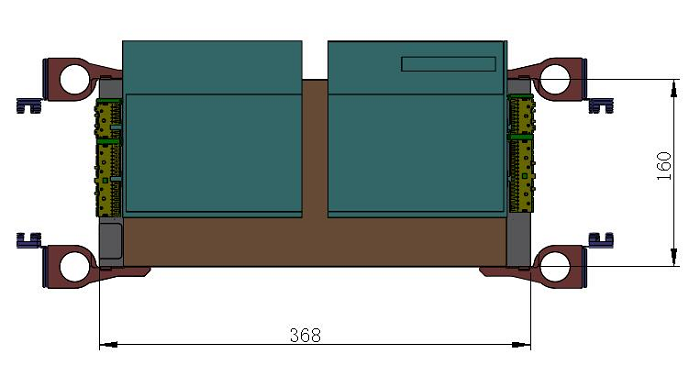

5. Battery Placement

6. Operation Process:

Open cabinet door → Place battery → Close cabinet door → Set parameters → Fixture clamps → Start heating → Start formation → Formation completes → Fixture releases → Open cabinet door → Remove battery

7. Equipment Features

1. Compatible with 3–12mm cell thickness, no need to adjust fixture or replace tab blocks

2. Uses spring-type nickel alloy contacts, easily pluggable contact boards, resistant to electrolyte corrosion, easy to clean

1. Basic Parameters

|

No. |

Parameter Name |

Specification |

Description |

|

1 |

Heating Method |

Fiberglass heating plate |

Independent temp. control per layer |

|

2 |

Temp. Control Method |

Independent per layer |

One-touch touchscreen setting |

|

3 |

Temp. Rise to 65℃ |

15–20 Min |

Target temperature: 65℃ |

|

4 |

Temp. Control Range |

Room Temp – 85℃ |

Accuracy: ±2℃ |

|

5 |

Pressure Output |

80–180 KG |

Cylinder ∅ 200mm |

|

6 |

Cylinder Drive |

Left to Right |

Parallel pressing |

|

7 |

Pressure Accuracy |

≤±5KG |

Top and bottom layers |

|

8 |

Execution Mode |

Independent by fixture; temp/pressure global |

One product type per cycle |

|

9 |

Pressure Setting |

Input cell size & pressure/time; auto-calculate |

Data can be saved & reused |

|

10 |

Plate Spacing |

22mm |

Optimal for operation |

|

11 |

Tab Contact |

Nickel alloy spring-type |

No plating, easy to clean |

|

12 |

Tab Block |

Teflon injection-molded |

Flame-retardant, corrosion-resistant |

|

13 |

Channels |

16 |

Controlled via upper software |

|

14 |

Voltage Output Range |

DC 20mV – 4500mV |

|

|

15 |

Voltage Accuracy |

±0.1%FS ±0.1%RD |

Resolution: 1mV |

|

16 |

Current Range |

DC 20 – 2000mA |

|

|

17 |

Current Accuracy |

±0.1%FS ±0.1%RD |

Resolution: 1mA |

|

18 |

Steps per Cycle |

1–32 |

|

|

19 |

Voltage Qualification Rate |

≥99% |

Excludes non-equipment factors |

2. Applicable Product Parameters

|

|

Parameter |

Range |

|

Cell Length (A) |

30–110mm |

|

|

Cell Width (B) |

35–100mm (excluding airbag) |

|

|

Cell Thickness (H) |

3–12mm |

|

|

Tab Spacing (C) |

5–85mm |

|

|

Tab Shoulder (D) |

≤25mm |

|

|

Tab Length (E) |

≥8mm |

|

|

Polarity Direction |

Airbag side is the positive side(adjustable) |

1. Modes: Constant current charge, constant current/voltage charge, constant current discharge, rest, and cycle. Cut-off conditions: voltage, time, final current, final capacity.

2. Step execution resumes on power loss, manual pause, software closure, communication error, or abnormal stop.

3. All step curves and test data are saved per battery; real-time and historical data viewable per channel; supports Excel export (single/batch), and auto-export after test ends.

4. Multiple inspection UIs: graphical, summary, classified, abnormal data views.

5. Supports protection per step for voltage, current, temperature, pressure, with alarm notifications.

6. Minimum PC requirements: PII/300 CPU, ≥2GB RAM, ≥250GB HDD, EGA/VGA display, keyboard & mouse, Windows 7+, 1 USB port, 1 Ethernet port.

7. Operation software included; PC supplied by user.

8. Protection Functions:

(1) Over-voltage, under-voltage, over-current, under-current, over-capacity

(2) Configurable voltage/current protection values, alerts & logs

(3) Temp/pressure over-range alarm lights

(4) Emergency stop button: fixture stays closed, power off

(5) Smoke detector triggers buzzer alarm on detection

9. Three-color Indicator Lights:

Yellow: Standby (fixture not pressed)

Green: Operating (charging in progress)

Red: Fault (e.g., over/low temp/voltage, smoke, communication error)

1. Power Supply: AC380V, 50Hz, 3-phase 5-wire, voltage fluctuation ±10%

2. Max Power Consumption: 2KW

3. Compressed Air: 0.3–0.75MPa, fluctuation ±1% (clean, dry, oil-free)

4. Dimensions & Weight:

Weight: ~0.8T

Size: L1.2m × W0.82m × H1.6m

Color: Light gray or per customer

5. Environment:

Temperature: 0–45℃

Humidity: 30%–75%RH, dry, ventilated, acid/alkali-free

Ground: Protective grounding

|

No. |

Name |

Model |

Unit |

Qty |

|

1 |

Namecard Paper |

Customized |

Sheet |

12 |

|

2 |

Communication Cable |

3*0.3mm² Shielded |

Meter |

5 |

|

3 |

Plug |

Universal |

Piece |

20 |

|

4 |

Communication Module |

USB-RS485 |

Piece |

1 |

|

No. |

Name |

Spec/Model |

Unit |

Qty |

|

1 |

Air Switch |

NXBLE-63 C40 |

Unit |

1 |

|

2 |

Contactor |

CJX2-3210 |

Unit |

1 |

|

3 |

Contactor |

CJX2-2510 |

Unit |

3 |

|

4 |

Touchscreen |

TPC7012Es |

Unit |

1 |

|

5 |

Solenoid Valve |

4V220-08B |

Piece |

3 |

|

6 |

Solenoid Valve |

2V025-08B |

Piece |

6 |

|

7 |

Cylinder |

SC250 |

Piece |

1 |

|

8 |

PLC Controller |

CY-V22 |

Unit |

1 |

|

9 |

Temp Control Module |

TP27N |

Unit |

1 |

|

10 |

Load Sensor |

0–3T |

Piece |

1 |

|

11 |

Power Supply |

LRS-200-24 |

Unit |

1 |

|

12 |

Constant Current Source |

Neware 5V2A-16 |

Unit |

1 |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975