ItemNo :

LITH-JK-TMJ-220AMOQ :

1Warranty:

2yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comLab Vacuum Doctor Blade Film Coater Coating Machine

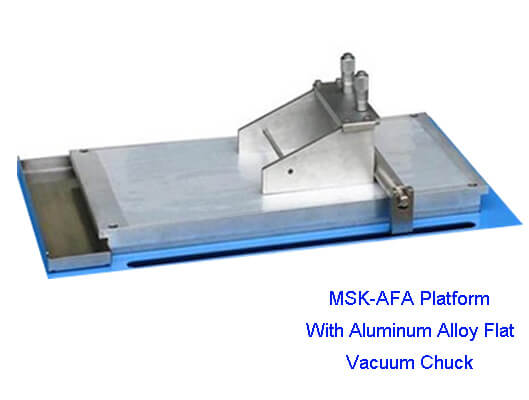

LITH-JK-TMJ-220A is a CE Certified Automatic Film Coater with vacuum chuck designed to produce films with consistent thickness by using micrometer adjustable applicators or fixed thickness applicators. It has a unique driving system to produce the smooth coating on all types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when coating on the thin substrate and making uniform tape casting. One micrometer adjustable applicator is included for immediate use. This machine can be used for research on ceramic tape casting and Li-Ion battery electrode coating.

Specifications

Stroke Length

10 - 200 mm adjustable by using Adjustable Position Switch

Platform

Aluminum alloy flat vacuum chuck

Accessories: Film Applicator

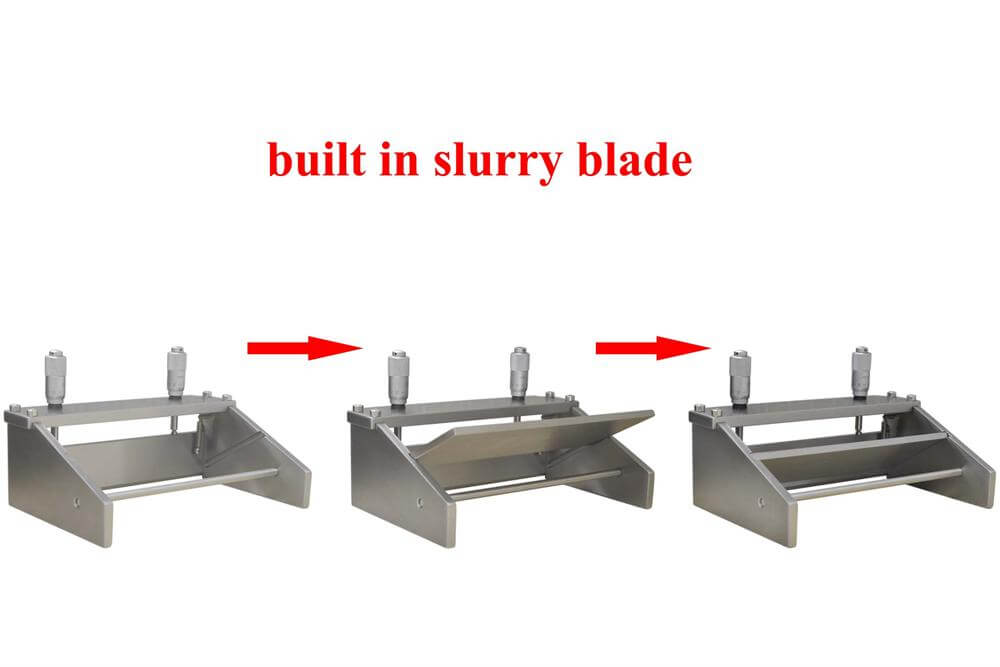

Optional 50 upto 180 mm width micrometer film applicator is included, with adjustable thickness from 0.02 mm - 2 mm

Optional Heating Cover Voltage and Power

110VAC or 220VAC

Traverse Speed

0 - 20 mm/sec variable

Vacuum Pump

Vacuum pump is included

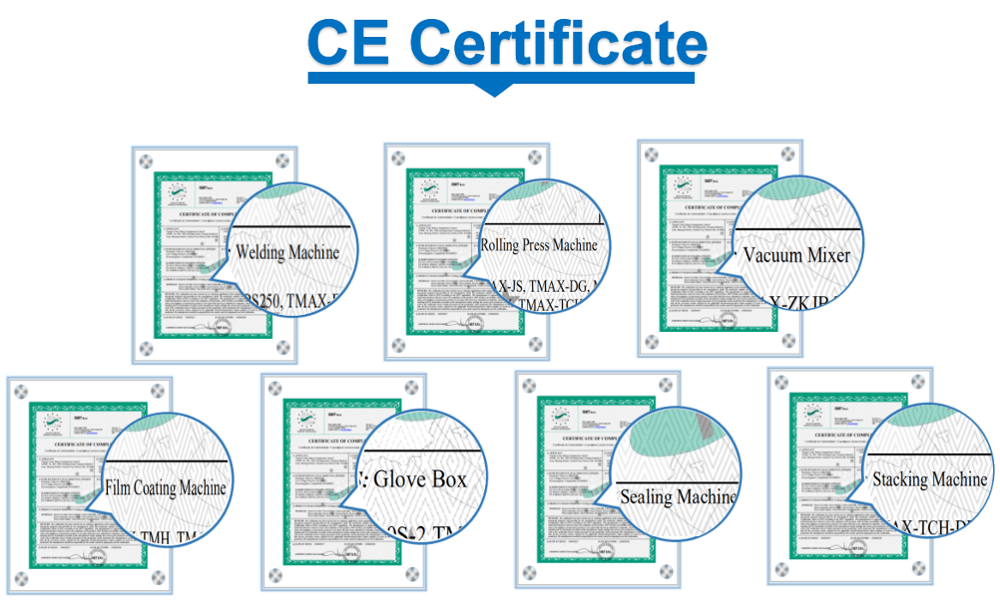

Compliance

CE Certificate

Warranty

Two years limited warranty with lifetime support

Vacuum Chuck Dimensions: 320mm(L) x 200mm(W)

Traverse Pusher is included for pushing the doctor blade to ensure constant speed coating

Note: Thinnest film can be achieved is > 20 micron

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975