ItemNo :

LITH-JS100MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

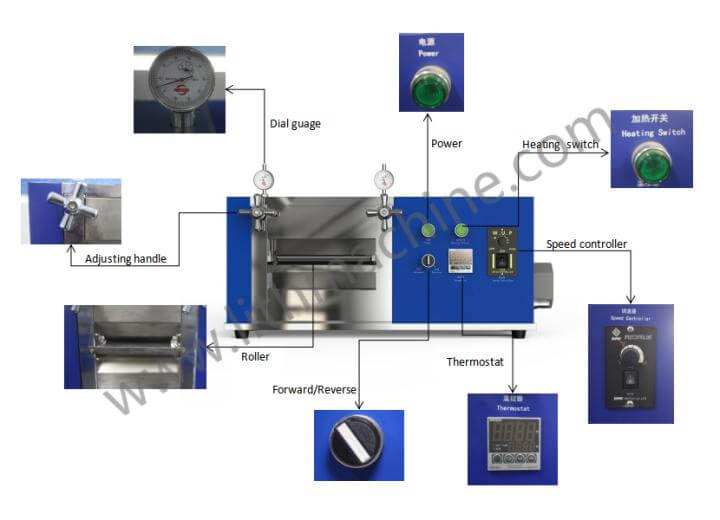

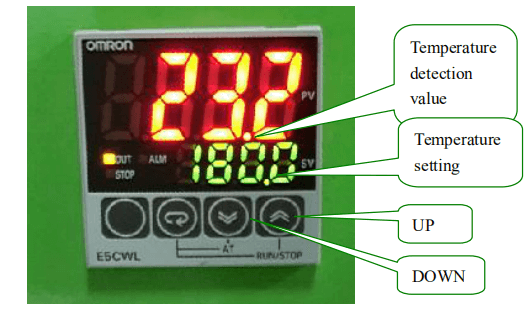

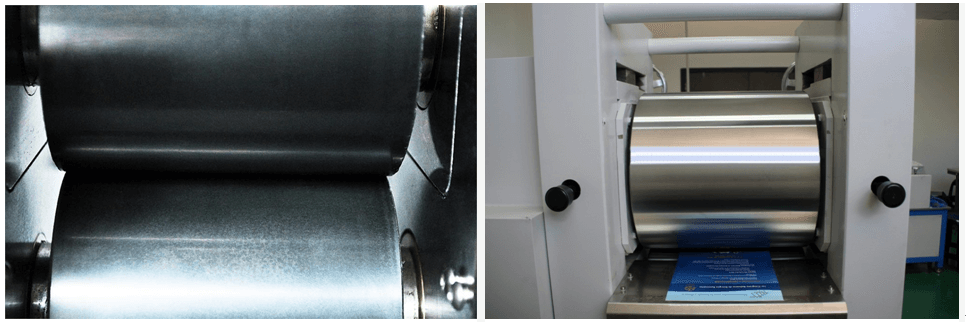

1. LITH-JS100 is compact Hot Rolling Cylinder Press, which is designed for preparing battery electrode for both inside or outside glove-box. High torgue DC moter is Ar gas compatible. It serves well in the application such as increasing active material density of the electrode in Li-ion batteries research after coating.

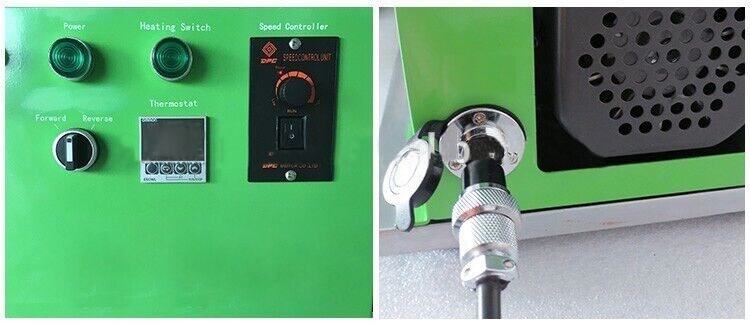

2. LITH-JS100 is equipped with 24V DC motor for a safe operation under Ar gas environment.

Specifications

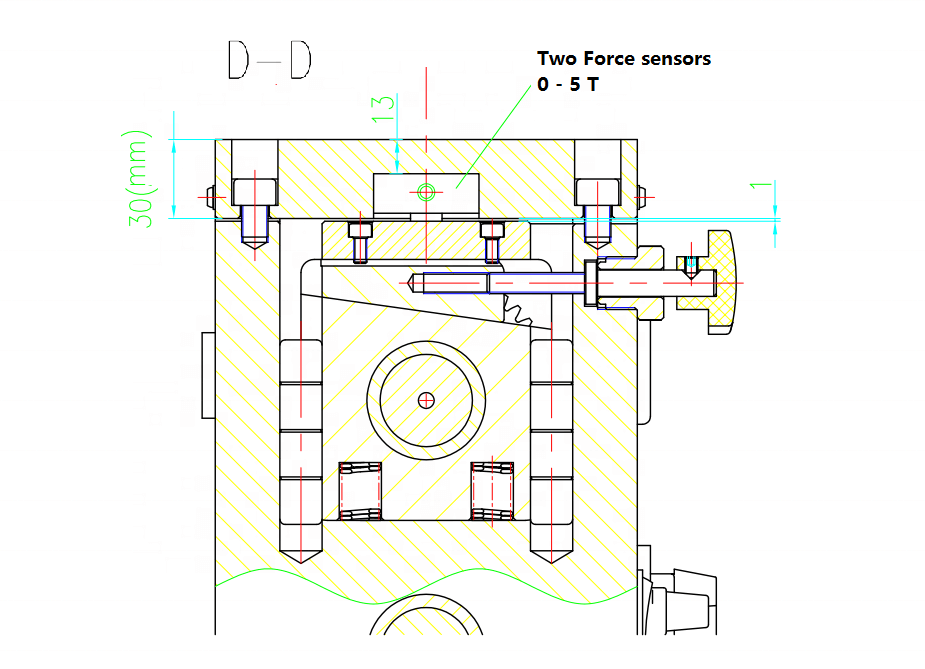

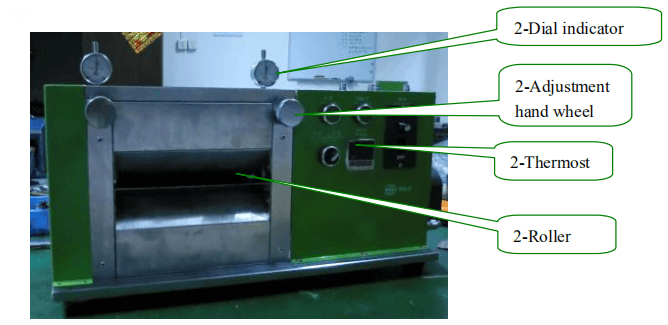

| Roller Size | 96mm(Dia.) x 100mm(W) |

| Effective Cylinder Width | 96mm |

| Product Thickness | 0~2 mm adjustable |

| Dial Gauge Accuracy | 0.01mm |

| Minimum Thickness |

Depending on the electrode's material and thickness, typically: A 0.16mm thick electrode coated on copper can be pressed into a minimum thickness of 0.1 mm A 0.06mm thick electrode coated on copper can be pressed into a minimum thickness of 0.04 mm A 0.33mm thick silver/gold can be pressed into a minimum thickness of 0.03 mm |

| Working Voltage | 110V - 240V AC, 50/60Hz, automatic switch for worldwide use |

| Roller |

1. Roller diameter tolerance: 0.004mm |

| Roller Surface Hardness |

62 HRC Never roll materials with hardness > 50HRC |

| Compliance | CE Certificate |

| Warranty | One Year limited warranty with lifetime support |

| Warnings |

1. Never roll materials with hardness > 50HRC 2. In order to prolong the lifespan of the roller bearings, regular lubrication is recommended. 3. Clean roller surface for each rolling and Use acetone to clean and lubricate when not in use to avoid corrosion. 4. This rolling machine can be used under Ar gas. |

| Dimension | L500mm*W360mm*H620mm |

| Net Weight | 50KG |

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975