ItemNo :

LITH-CP60MOQ :

1Warranty:

2yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Electrode Disc Punching Machine For Coin Cell Electrode Cutter

Features

LITH-CP60 is a compact disc cutter with quality sliding rail with ball bearing for precision cutting. It can be easily placed into a glove box with a transition chamber diameter larger than 230mm. This tool is manually operated and is designed for cutting round discs from a thin metal sheet/foil (< 0.5 mm) or separator film (<30um). The resulting discs can be used as electrode/separator discs of split test cell and coin cell for battery researchers as well as TEM sample preparation.

Specifications

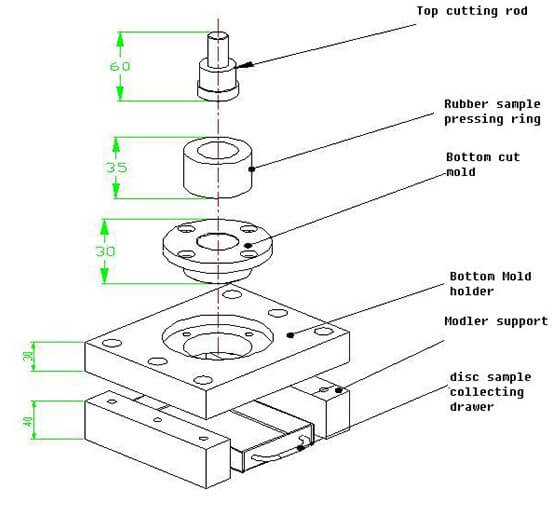

Structure

Major structural material: Cr Plated Steel

Cutting Die

Optional 3 - 24mm customized dies are available upon request

Product Dimensions

L110×W150×H235mm

Compact size which can be put into glovebox through air lock chamber

Warranty

Two years limited manufacturer warranty with lifetime support.

Application Notes

1. If you are going to make CR2016, CR2025 or/and CR2032 coin cell batteries, you will need at least three cutting dies:

Compliance

CE Certified

Net Weight

6 kg

16mm (for negative side case, which is 16.5mm in diameter).

19mm (for positive side case, which is 20mm in diameter).

20 mm (for separator to fully separate the electrodes in both negative and positive cases).

2. For CR2450 coin cells, a 20mm cutting die can be used for cutting electrode discs and the 24mm cutting die can be used for cutting either electrode discs or separator discs (the 24mm cutting die can be purchased as optional die).

3. Separator discs must be large enough to fully separate the positive and negative electrodes to avoid short-circuit inside the coin cells

4. Warning: You must pay great attention to install die or change die from one size to another. The tolerance of precision die is very little. Please contact us if you have any question.

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975