ItemNo :

LITH-VGB-6MOQ :

1Warranty:

2yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.comVacuum Glove Box Chamber for Lab Research

Features

Closed Loop Gas Circulation Inert gas in a closed loop. The gas is circulated by the blower and purifier, H2O, O2 can be removed continuously. Closed Loop Gas Circulation

Auto Purging

The replacement of the atmosphere inside the glove box can be achieved automatically by the purging valves.

Automatic Regeneration

H2O and O2 removal material can be regenerated. The regeneration process can be program controlled.

Automatic Pressure Control

The pressure in the glove box is controlled automatically by the Programmable Logic Controller (PLC). Working pressure can be set between +10mba and -10mba. If the pressure goes over+/- 12mbar, the system will be protected automatically.

Eco Mode

The vacuum pump will be activated automatically when necessary, and will turn off after a period of idle time. Blower frequency will be switched to 25Hz when moisture and oxygen level reaches to less than 1 ppm

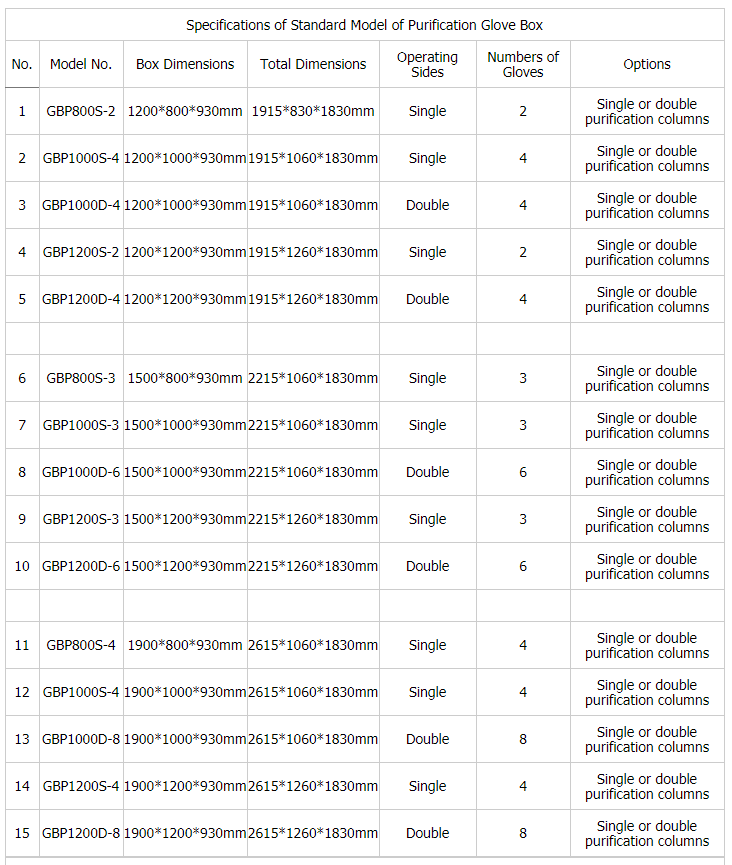

SPECIFICATIONS:

Model

LITH-VGB-6

Source voltage

AC110V-240V, Customized

Warranty

Two Years limited warranty with lifetime support

Type

Single section single station

Dimension(L*W*H)

SUS304 stainless steel plate, 1200*800*930mm

Total dimension(L*W*H)

SUS304 stainless steel plate, 1915*830*1830mm

Big transitive cabin

SUS304 stainless steel, DN385*588mm

Small transitive cabin

SUS304 stainless steel, DN150*350mm

Gloves

2 pcs, butyl material, thickness : 0.4mm

Gloves port

DN215mm, Acid and alkali resistant material PPS

Purification system

Single purifying column,

With the remove of water, oxygen function

Control system

6 inch color touch screen, SIEMENS

Vacuum pump

4L/S

Pressure sensor

-2500~2500Pa, Touch screen

H2O concentration

<1 ppm (20 °C, 1 atm) Touch screen

Oxygen concentration

<1 ppm (20 °C, 1 atm) Touch screen

Organic solvent filter

21 L

Working gas

N2,Ar,He

|

Notes: |

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975