- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SLBNMOQ :

1Place of Origin:

ChinaColor :

optionalPort :

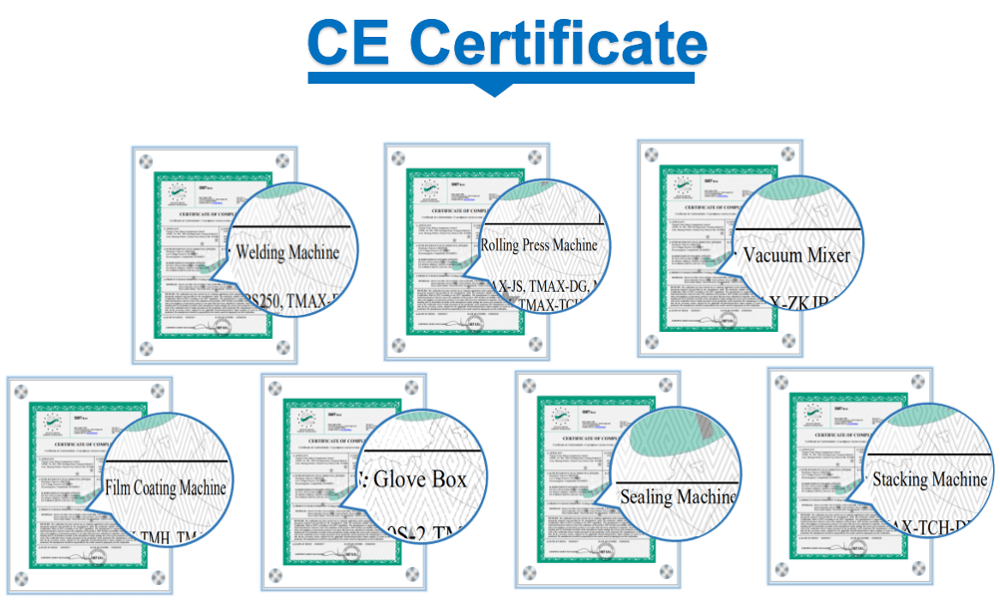

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 days

FEATURE

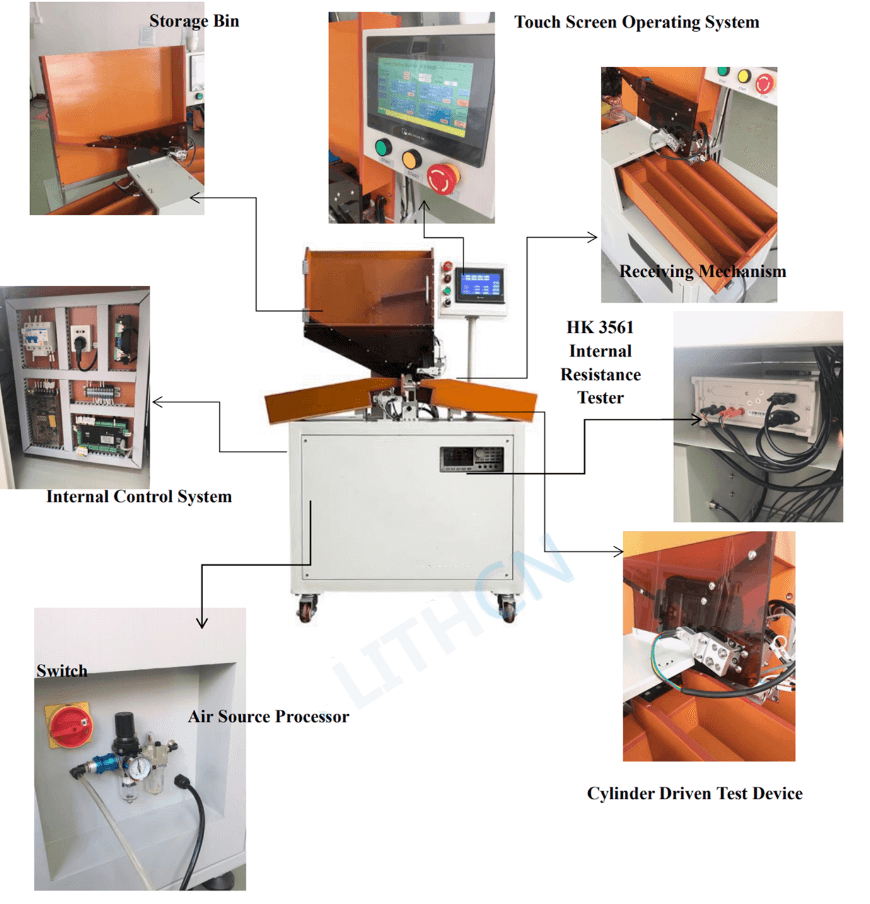

The cylindrical 18650 battery automatic sticker sorting machine is a test sorting device for checking the internal resistance and voltage of the cylindrical battery after the surface mat, and comes with a high-precision internal resistance and voltage automatic test system. The internal resistance and voltage value set on the computer software accurately feed the battery to the specified gear position, and the system can realize 11 sorting (10 test stations, 11 sorting levels) sorting. The overall design efficiency of this equipment is about 4,500-5000 batteries per hour, and the structure design is simple and generous, and the performance is stable. In the market, it has been a cost-effective sticker and sorting combination integrated equipment. The two machines are loaded and received in the same direction. They can be combined with single operation or separately.

1. Professional control system, stable and reliable drive subdivision high speed.

2. The device can send the battery to the specified gear according to the set internal resistance voltage value.

3. Special knife mold anti-adhesive air die automatically punches the surface pad and accurately sticks to the battery end face.

4. The average sorting is 4500PCS/hour with high stability.

SPECIFICATION

11 Chanel Battery Sortting Machine

|

Model |

TMAX-FN-011 |

|

Power supply |

AC220V ± 10% 50Hz |

|

Voltage |

900W |

|

Sorting parameters |

Open Circuit Voltage and AC Internal Resistance |

|

Compressed Air Pressure |

0.5 ~ 1.0Mpa |

|

Sorting Speed |

≥80PPM |

|

Productivity |

5000pcs/h |

|

Dimension |

1320x880x1450mm |

|

Adaptation Battery |

Cylindrical Battery (18650,32650,18500,26650,14500,21700 etc.) |

|

Receiving Channel |

11 channels |

|

Internal Resistance Tester |

HIOKI3561 or HK3561 |

|

|

HIOKI3561: Open circuit voltage accuracy:± 0.01% rdg; Display Resolution: 0.1 millivolt; Internal impedance accuracy:± 0.1% rdg; Display Resolution: 0.01 mΩ

HK3561: Open circuit voltage accuracy: ± 0.05% rdg; Display Resolution: 0.1 millivolt; Internal impedance accuracy:± 0.3% rdg; Display Resolution: 0.01 mΩ |

|

Total weight |

280kg |

|

Control component |

7.5 inch touch screen, 3-axis PLC programmer |

|

Motion device |

Closed-loop stepper motor is used for shifting, accurate positioning and synchronous belt conveying the core to prevent the surface of the core from being damaged. |

|

Feeding |

Using hopper feeding mode, 500 PCS can be put in one time. |

|

Data storage |

Test data can be stored on a U disk |

|

Scan code function |

Can be customized |

|

Automatic Online Interface |

It can be customized to connect the outlet of the automatic surface cushion machine in the machine hopper to realize the automatic connection of the electric cores and save the labor cost. |

|

Other |

Customizable scanner and database data docking |

|

|

Optional Distribution Core Dynamic Tester, reflecting the quality and load-carrying performance of the core |

|

|

Customizable automatic connection automatic surface mattress machine (electric core poured into automatic surface mattress machine, pasted surface mattress automatically flowed into automatic sorter, sorting, saving manpower) |

|

|

Automatic collection of production quantity to show current production efficiency |

Equipment Configuration List

|

Tester |

HIOKI3561 or HK3561 |

|

Computer |

Industrial Computer |

|

PLC |

FX3U-80MT/ES-A and SC-09 |

|

Servo |

Panasonic A5 Series |

|

Sensors |

Panasonic and Omron, Japan |

|

Guideway |

ShangYin, Taiwan |

|

Bearing |

Japan NSK |

|

Cylinder |

Adec |

|

Indoor temperature |

- 30 ℃ ~ 70 ℃ |

|

Factory |

No pollution and no strong electromagnetic interference |

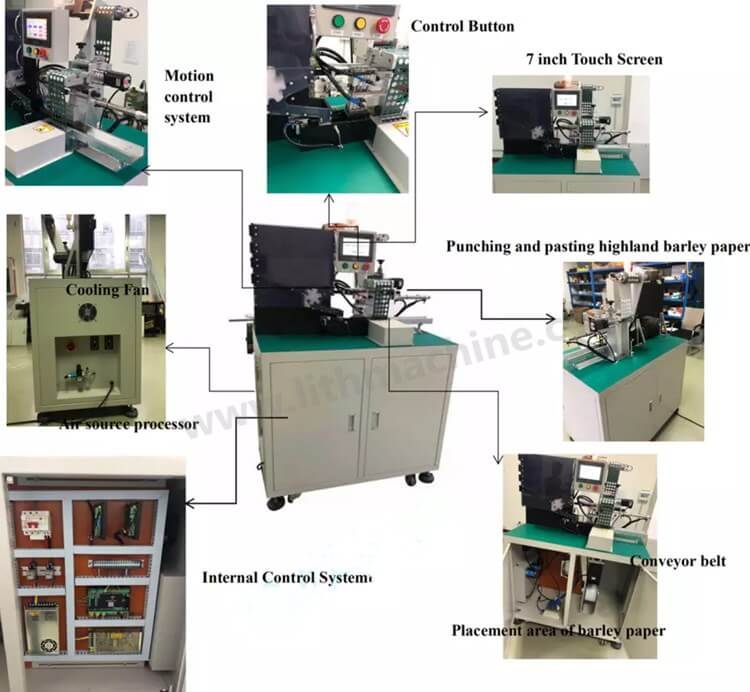

18650 Battery Automatic Sticker Machine

|

Input gas source |

0.4-0.8Mpa |

|

Function Style: |

stepper drive with pneumatic |

|

Input voltage: |

AC220V |

|

Sticker Matrials: |

Barley paper or PVC |

|

Sticker Matrials Size: |

Barley paper Maxium 350mm;Scroll Internal Diameter 72-75MM |

|

Adaptable Battery Cell |

18650 battery Plus-n-Minus |

|

Power: |

Electric power or pneumatic |

|

Control Instrument: |

7.5feet contact screen,PLC programming machine and step motor |

|

Electrodes to the body distance: |

100 mm (Scalable adjustable) |

|

Producivity: |

4000pcs/h; singal 4pcs |

|

External dimensions |

1.3M*1M*1.3M |

Battery Sorter(Optional Channel)

Paper Sticker

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588