ItemNo :

LITH-10060ZMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysSemi-Auto Lithium-Ion Battery Winding Machine for Prismatic Cells

1. Equipment Function Description

This machine is mainly used for the precise winding of prismatic lithium-ion battery cells.

The working process is as follows: the operator manually inserts the cathode and anode sheets into the winding unit, interleaves them with the separator, and winds according to the process requirements. The machine then automatically applies the termination tape and discharges the wound cell.

2. Equipment Functions and Features

1. Adopts dual winding needle structure.

2. Manual electrode loading – automatic winding – automatic needle change – automatic tape application – automatic cell discharge.

3. Termination tape is applied longitudinally (parallel to the tabs); the tape is applied smoothly with precise control, without pulling the cell; tape application is stable and reliable.

4. Winding needle speed is adjustable.

5. Two separator rolls with active unwinding; tension controlled via encoder feedback and high-precision proportional air valve to maintain constant tension; tension can be smoothly adjusted during winding.

(Tension control as shown in diagram:)

6. Equipped with electrode dust removal device.

7. Cell tail wrapping can be performed with electrode or separator.

8. The wound cell is free of damage, core pulling, or electrode misalignment.

9. Easy operation; size and specification adjustments are simple and quick.

3. Process Flow

This machine conforms to the standard winding process for prismatic lithium-ion batteries: the separator fully wraps the anode, and the anode wraps the cathode.

Process steps:

1. Separator pre-winding: uses heated welding with serrated blade to cut separator, reducing pre-wound length, avoiding separator stringing and surface marks on cells.

2. Insert anode: manually insert the anode sheet into the winding section.

3. Insert cathode: manually insert the cathode sheet into the winding section.

4. Winding.

5. Indexing rotation for station change.

6. Separator cutting, tape application, and cell discharge.

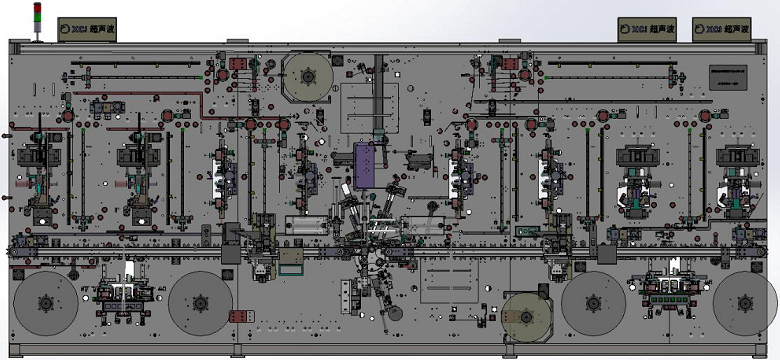

4. Equipment Structure

This equipment is made up of a winding unit, indexing unit, separator unwinding unit, electrode guiding unit, tape application unit, cell discharge unit, and control system.

Winding Unit (2 sets): It is equipped with offset winding needles to guarantee winding precision, and the winding needles can be replaced effortlessly.

Indexing Unit (1 set): It is used for switching between the winding station and the tape application station through indexing rotation.

Separator Unwinding Unit (2 sets): It adopts active unwinding, with tension adjusted and controlled by pneumatic means.

Electrode Guiding Unit (2 sets): It features single-side adjustment, making operation simple and convenient.

Tape Application & Discharge Unit (1 set).

5. Technical Specifications

1. Separator Width: 25–100 mm

Winding Needle Specification: 16–60 mm

Electrode Width: 23–98 mm

2. Material Specifications (unit: mm):

|

Material |

Length |

Width |

Thickness |

Inner Dia |

Outer Dia |

|

Cathode Sheet |

180–2000 |

23–98 |

0.1–0.2 |

|

|

|

Anode Sheet |

180–2000 |

23–98 |

0.1–0.2 |

|

|

|

Separator |

Roll |

25–100 |

0.016–0.045 |

76.2 |

250 |

|

Termination Tape |

Roll |

8–20 |

0.01–0.035 |

76.2 |

150 |

3. Production Capacity: 6–10 pcs/min (depending on needle width and electrode length/width)

4. Winding Accuracy:

Provided the following conditions are met:

l Electrode width deviation < ±0.2 mm

l "S" bend deviation < ±1 mm/500 mm

l Separator roll cone deviation < ±0.2 mm

The winding accuracy meets the following:

l Separator alignment deviation < ±0.5 mm

l Electrode alignment deviation < ±0.5 mm

l Capable of anode-wrapping-cathode and separator-wrapping-anode

l Final cut alignment deviation of ±0.5 mm

5. Pass Rate: ≥98% (excluding non-equipment factors)

6. Technical Standards

|

Specification |

Value |

Remarks |

|

Input Power |

AC220V, 1KW, 50Hz |

|

|

Compressed Air Source |

0.4–0.6 MPa |

|

|

Production Capacity |

6–10 PCS/min |

|

|

Equipment Weight |

Approx. 800 kg |

|

|

Dimensions |

1660 mm × 1300 mm × 1570 mm |

L×W×H, excluding electrode tray |

|

Winding Needle Spec. |

10–18 mm / 16–60 mm |

|

|

Mechanical Configuration |

Machine Frame & Mounting Plate |

1 set |

|

Winding Needle Unit |

1 set |

|

|

Electrode Feeding Units |

2 sets |

|

|

Separator Feeding Units |

2 sets |

|

|

Tape Application Unit |

1 set |

|

|

Control System Specifications |

PLC |

PANASONIC AFRX-C60T |

|

Touch Screen |

MCGS / WIGERLON, 7-inch True Color |

|

|

Winding Motor |

YANKONG / LISAN – Stepper Motor |

|

|

Tension Motor |

YANKONG / LISAN – Stepper Motor |

|

|

Sensors |

PANASONIC / DFC / Daochuan |

|

|

Pneumatic Components |

AIRTAC / XINGZHEN / Airtac |

|

|

Alarm System |

Fault Stop Fault Prompt: Built-in Program One-Key Reset |

|

|

Accessories |

Operation Manual |

1 set |

|

Spare Parts |

1 set (See Delivery List) |

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588