- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-PM-8MOQ :

1Warranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

5 days

Details show

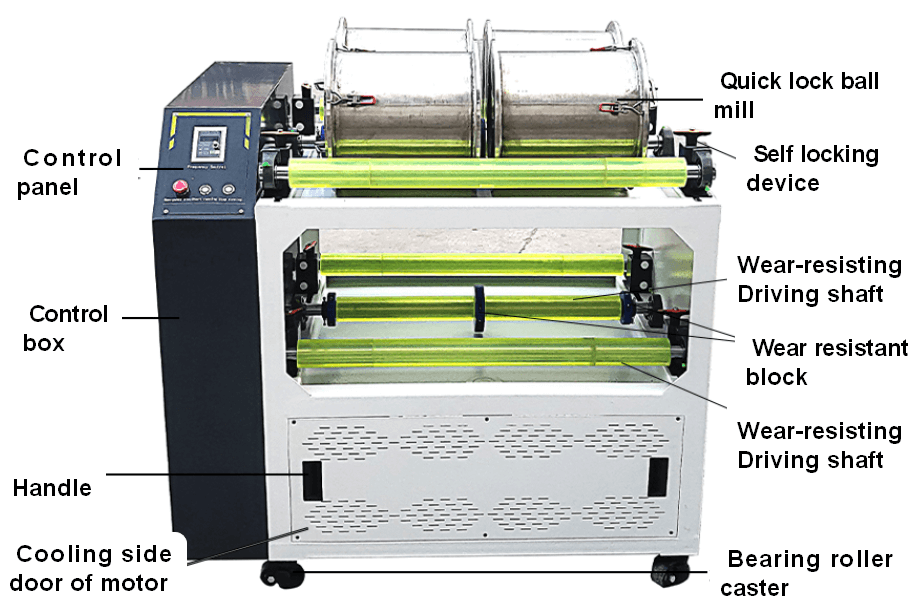

Quick lock ball mill tank

Adopt this kind of fast lock fixed way, solve the trouble of lock screw, configure portable hook device, convenient handling. You can also choose semi-automatic lifting ball material separation system, fast lifting jars and handling balls material separation.

Self-locking device

Wearable objects

Tank mill ball mill is a laboratory, small batch production with ultra-fine grinding, mixing equipment. This machine is beautiful and novel, compact structure, easy to operate, high efficiency,uniform grinding particle size, is the scientific research, teaching, test, production of preferred equipment. It can be widely used in electronic materials, magnetic materials, biological medicine, ceramic glaze slurry, metal powder, non-metallic minerals, new materials and other industries.

Characteristics

1.It can be used in single or multiple cans at the same time, and multiple samples can be ground at the sametime;

2.Timing, intermittent shutdown or continuous cycleoperation;

3.The outer wear-resistant adhesive parts of the shaft are made of special materials, which aredurable;

4.Suitable for material fine grinding, crushing, mixing, material precipitation prevention and other technological requirements, highefficiency

5.Can be customized according to customer requirements (multi-station customization, multi-stage power output customization,etc.);

|

Name |

PM-2-5 |

PM-2-15 |

PM-2-20 |

|

Overall dimension |

950*480*690 |

1130*550*700 |

1350*650*700 |

|

Weight(kg) |

60KG |

80KG |

95KG |

|

Specification |

Y0.75-4B3 |

Y1.5-4B3 |

Y2.2-4B3 |

|

Frequency converter |

0.75KW/220V |

1.5KW/220 |

2.2KW380V |

|

Roller speed(r/min) |

50-450 |

40-420 |

40-340 |

|

Maximum load per jar |

35KG |

80KG |

120KG |

|

Handgear/protective cover |

optional |

optional |

optional |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588