- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ITT-300SMOQ :

1Delivery Time:

5 daysLab 300ML Rotary Stirring Vacuum Mixing Defoaming Machine

Summarize

Technical specification

|

Name |

Vacuum mixing defoaming machine |

|

Equipment type |

ITT- 300S |

|

Maximum capacity |

150~500g*2; 10~150mL*2 |

|

Standard container |

300ML(HDPEφ78×90) or 150ml (HDPE φ60*72); Syringes below 30CC |

|

Mode of operation |

Man-machine interface + button start |

|

Velocity of revolution and velocity of rotation |

Revolution 100-2500RPM Rotation to revolution ratio 0.65 |

|

Revolution |

100rpm to 2500rpm stepless speed control, adjust 1rpm according to the actual requirements of the user |

|

Centrifugal force |

Up to 400G |

|

Vacuum gauge |

SMC or Panasonic vacuum meter objectively displays the vacuum degree |

|

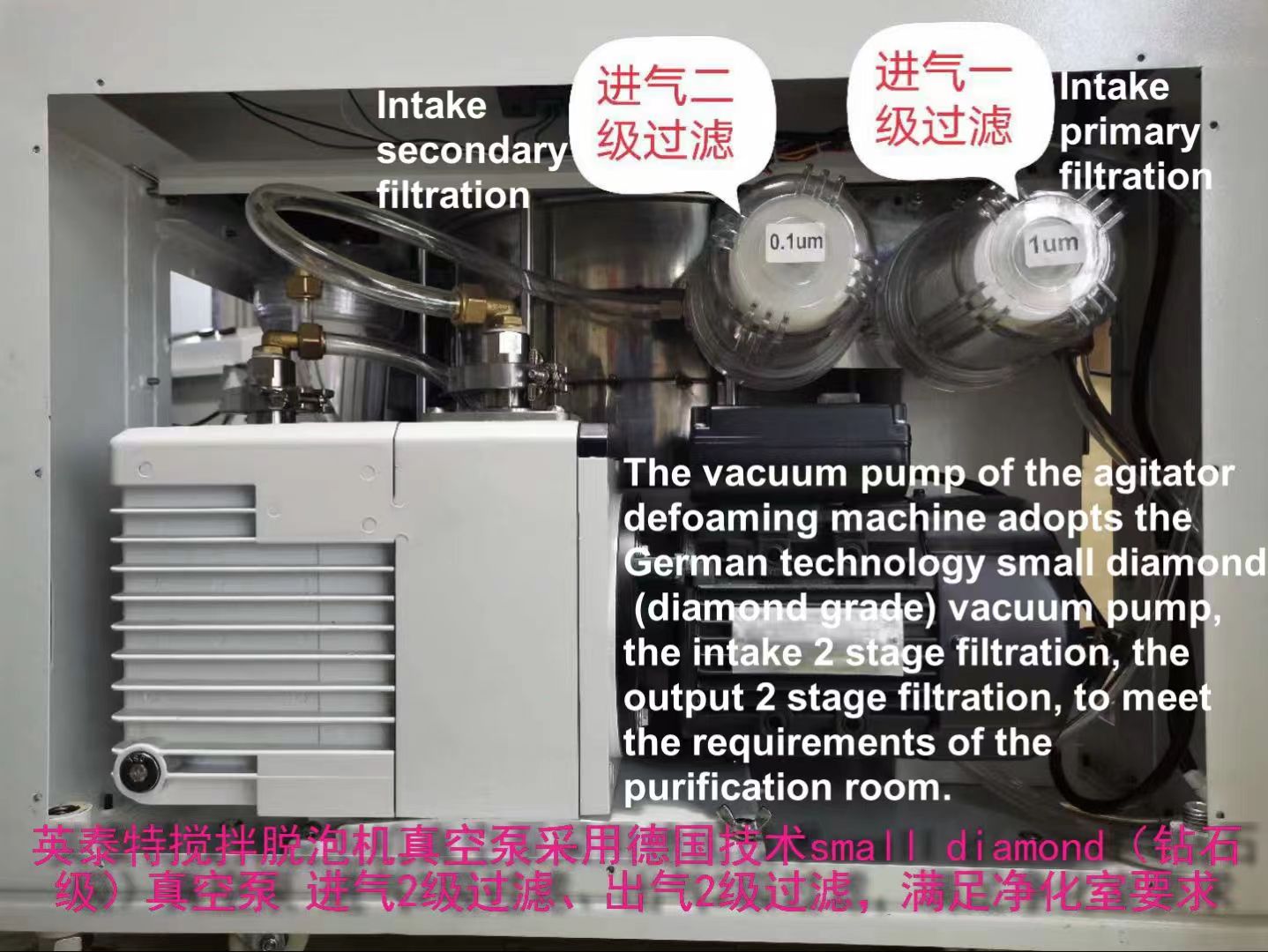

Vacuum pump |

German technology Small Diamon vacuum pump, equipped with forced lubrication oil pump, sufficient lubrication, reliable performance, low noise, with our company's unique 4-stage filtration, to meet the requirements of the purification room. |

|

Principal axis |

S136 mirror die steel seal quenching HRC58~60°, seal ring position mirror grinding |

|

Sealing ring |

Germany Bayer company polymer fluorine graphite sealing ring ultra-wear-resistant, maintain long-term high vacuum |

|

Swivel |

Imported aviation magnesium aluminum 7075, the overall machining center distance is ±0.02, the size is long-term stable |

|

Drive |

Modular structure, high interchangeability, very convenient maintenance. |

|

Stored program |

Adopts spiral umbrella tooth transmission, smooth transmission, low noise, long life |

|

Protection |

5 stored programs (each program can be set to 5 steps) |

|

Length * width * height |

L670×W560×H610mm |

|

Main engine weight |

120KG |

|

After sale |

The whole machine warranty is one year, lifetime maintenance |

|

Use |

Suitable for dispersion, mixing and defoaming of multi-component materials (silica gel, multi-component epoxy resin, etc.) |

|

Set time |

0 to 3000S x 5(five steps in total), with the accuracy of 1s |

|

Overall vacuum |

Relative pressure value -100KPa, accuracy 0.1KPa; Absolute pressure < 100Pa(< 1mbar) |

|

True empty source |

Built-in two-stage advanced vacuum pump 240L/ min (=4L/ SEC =14~16m3/ h); Absolute limit pressure (partial pressure 5*10-2Pa and 0.05Pa) Absolute limit pressure (total pressure 4*10-1Pa and 0.4Pa) |

|

Vacuum setting |

Vacuum independent switch, with vacuum delay function, vacuum degree arbitrary adjustment |

|

Shaft bearing |

Japan NSK bearing |

|

Control system |

Man-machine dialogue, Chinese interface, touch screen operation |

|

Balance regulation |

Dual cup configuration balance |

|

Transmission mode |

Gear drive |

|

Working principle |

Mass rotation without wing type centrifugal gravity |

|

Alarm device |

When running, the upper cover is not covered, there will be an alarm |

|

Security protection |

When the upper cover is locked during operation, the upper cover stops working when it is opened |

|

Applicable temperature and humidity |

10~40 ℃; 20~80%RH (no foggy moisture, OK) |

|

Voltage |

AC220V±5%; Single-phase; 50~60Hz |

|

Power |

≦ 1.0KW, rated power of the main engine 1000w including vacuum pump, standby 15W |

|

Equipment characteristics |

The maximum centrifugal gravity produced by rotation and revolution is nearly 400G, strong dispersion and defoaming; There is no spiral blade to achieve mixing and dispersion in the container; No need to clean, will not pollute the material; Does not damage the material (especially fibrous material) properties; Man-machine interaction, easy operation; Ultra-small, ultra-light, ultra-quiet optimized design. |

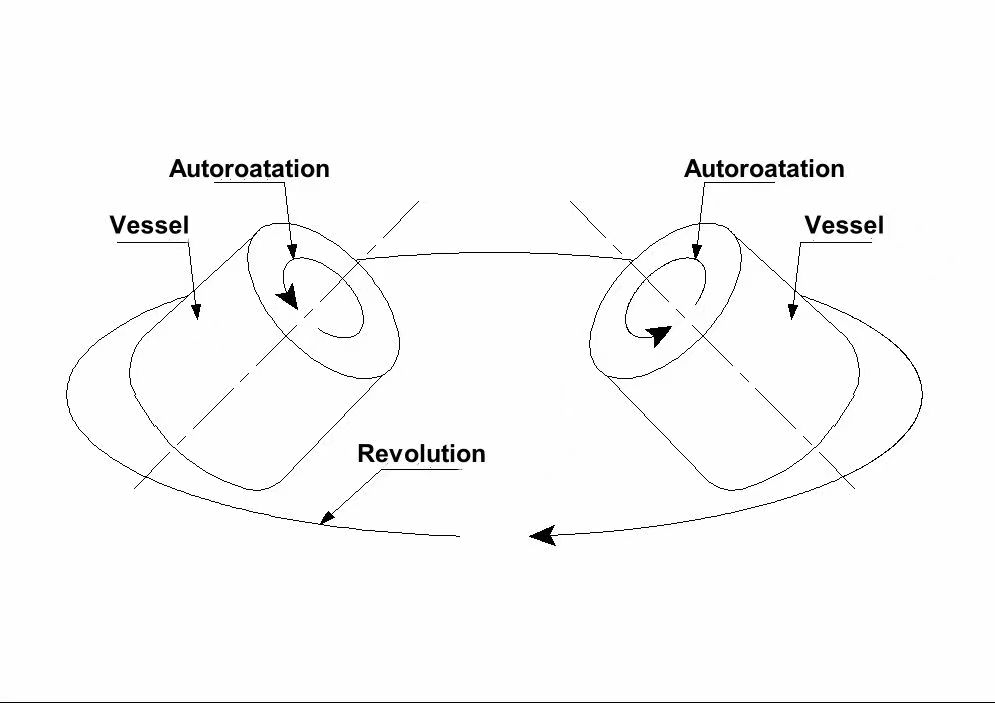

The working principle of the equipment is introduced

Non-contact mixing working principle diagram

The outer ring arrow is the direction of the equipment revolution, the material cup is placed in the cup holder at a 45 degree Angle, the small ring arrow is the direction of the material cup rotation, by the centrifugal gravity generated by two different sizes and directions of the same high-speed rotation to mix the slurry in the cup.

Our method of mixing: no mixing rod, mixing different materials is only to change the container. Easy to clean, just clean the container. Some customers directly use disposable containers, we provide customers with disposable cup fixtures within the scope of size tolerance.

The characteristics of stirring defoaming machine are introduced

a. Spindle: The use of Swiss S136 mirror die steel, after multiple heat treatment, the overall hardness of HRC62 degrees. Shaft whole grinding, full runout not more than 1 wire. After mirror grinding, the sealing surface achieves the surface roughness of 0.02um mirror effect, the friction coefficient is very low, the wear of the sealing ring is very small, and the high sealing performance of ultra-long life is achieved. This is one of the magic weapons that many of our customers maintain negative pressure above -98Kpa after several years of use.

b. Sealing ring: The use of Germany Bayer company ultra-wear-resistant sealing ring, wear resistance can reach 40M/S line speed, our equipment at 2000 RPM line speed of 4M/S. The pressure can withstand 20KG/c㎡. This is the second magic weapon for many of our customers to maintain negative pressure above -98Kpa after several years of use.

c. Vacuum pump: German technology Small Diamon vacuum pump, equipped with forced lubrication oil pump, sufficient lubrication, reliable performance, low noise, with our company's unique 4-stage filtration, to meet the requirements of the purification room.

d. Gear: Adopts the helical bevel gear type structure of the car, stable operation, low noise, long life.

e. Swivel arm: The use of integral swivel arm, all imported from the United States of aviation magnesium aluminum 7075 integral processing, to ensure the accuracy and later stability of the product, the center error is not more than ±0.02. High interchangeability, the same type of machine arm into arbitrary interchangeability, easy maintenance.

f. Vacuum stirring defoam machine: high vacuum, long life (on time oil change maintenance and maintenance of the machine 10 years vacuum degree will not be less than 3%, the vacuum degree is maintained below -98Kpa, the more negative vacuum degree is higher), easy maintenance: the overall material processing of the rotor arm is strong interchangeability, customers can easily change their own parts, you can also send back to our company to change parts. After replacing the parts, the effect is like a new machine.

Including the packing box: the length is 80CM, the width is 65CM, the height is 87CM, the weight is about 150kg.

Machine appearance: length is 76CM, width is 56CM, height is 69CM, weight is about 120 kg.

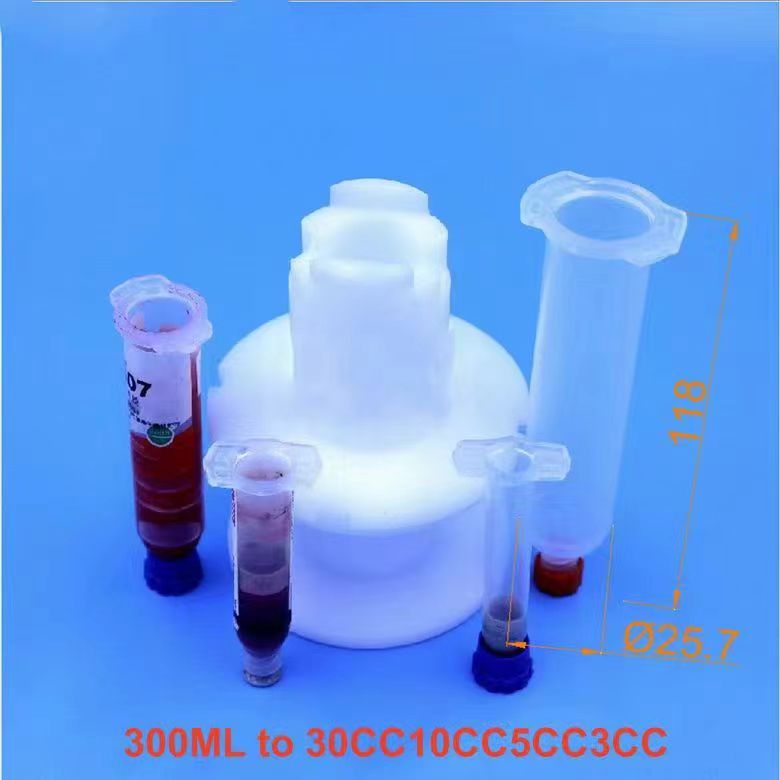

Optional tooling: 1*2 30CC syringes in the center (10CC, 5CC, 3CC syringes through the transfer sleeve), 4*2 10CC, 5CC syringes can be placed around.

|

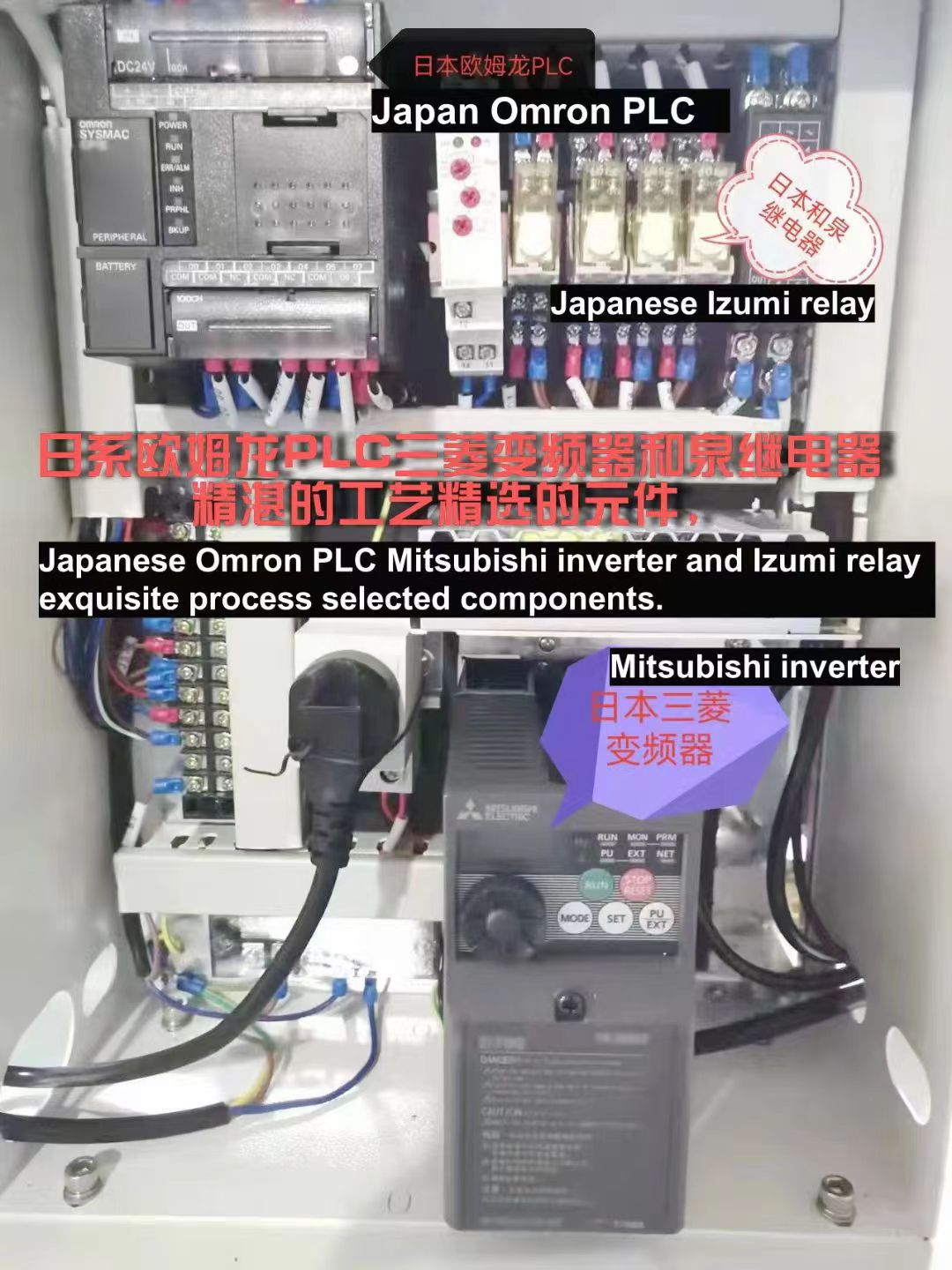

Configuration list of ITT-300S |

|

|

Part name |

Brand |

|

Touch screen |

SamKoon |

|

Programmable controller (PLC) |

OMRON |

|

Motor driver |

Mitsubishi |

|

Relay |

IDEC |

|

Vacuum gauge |

SMC or Panasonic |

|

Vacuum solenoid valve |

SMC |

|

Switching power supply |

MW |

|

Vacuum pump |

AKS Two stage pump SD-240(> 4L/ s, > 240L/ min, 14~16M2/ h) Machine digital display relative value vacuum maximum -100.2KPa |

|

Helical bevel gear, helical gear |

Custom MC901 or oily nylon |

|

Swivel |

7075 aluminum sheet processing |

|

Mixing cup |

300ML 150ML 40ML |

|

Axis of rotation |

S136 mirror die steel |

|

Rotating seal ring |

Custom Bayer fluorinated graphite seals |

List of machines and mixing cups

|

Serial number |

Name |

Specification |

Quantity |

|

1 |

Two cup stirring defoaming machine |

300ML |

1 |

|

2 |

Mixing cup |

300ML |

10 |

|

3 |

Mixing cup |

150ML |

10 |

|

4 |

Mixing cup |

40ML |

10 |

|

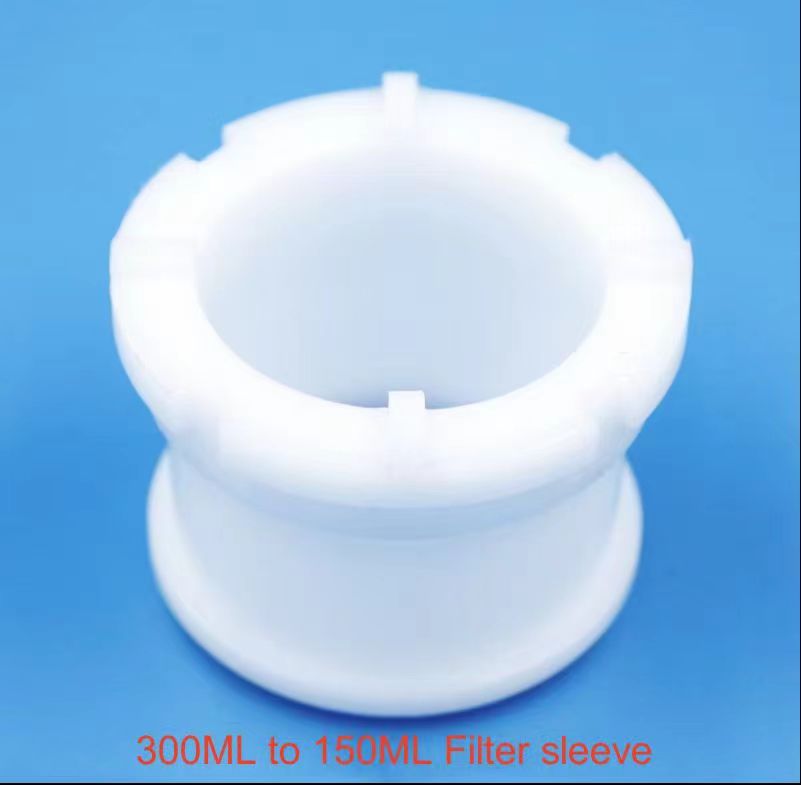

5 |

Transition sleeve |

300ML to 150ML |

2 |

|

6 |

Transition sleeve |

300ML to 40ML |

2 |

|

7 |

Counterweight |

300ML |

1 |

|

8 |

Counterweight |

150ML |

About 90 grams |

|

9 |

Counterweight in the cup |

40ML |

About 20g |

Mixing material PE+PP

Teflon cups purchased separately

Standard: 300ML cone bottom mixing cup

300ML to 150ML transition sleeve and mixing cup

300ML to 40ML transition sleeve and mixing cup

Optional accessories

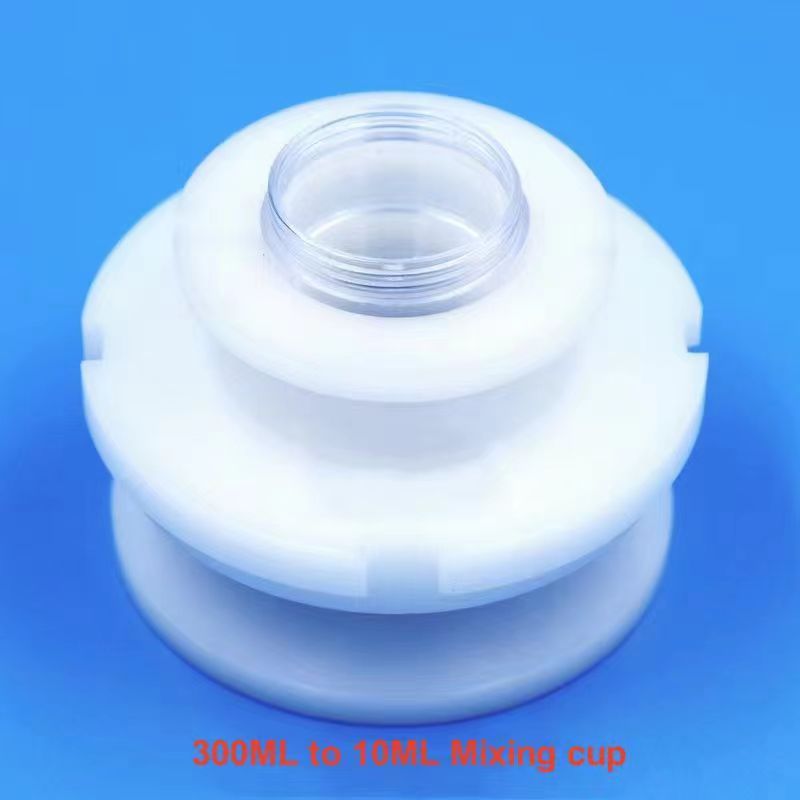

300ML to 10ML 300ML to 5ML

300ML syringe 30CC10CC5CC3CC syringe

Custom glass beaker or teflon beaker fixture

According to the characteristics of the glass, we have designed safety protection, but the glass is still at risk of cracking.

Disposable plastic cups and fixtures

It can configure 1000 disposable cups and provide purchase website at the same time.

High viscosity 10ML transfer tool

50ML10:1 50ML2:1

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588