- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-TSG-200MOQ :

1Warranty:

2yearsDelivery Time:

5 days

High-speed Dry Electrode Mixing Granulator Pelletizing Machine With Dispersion, Mixing, Granulation, Coating Function

Ⅰ、Introduction

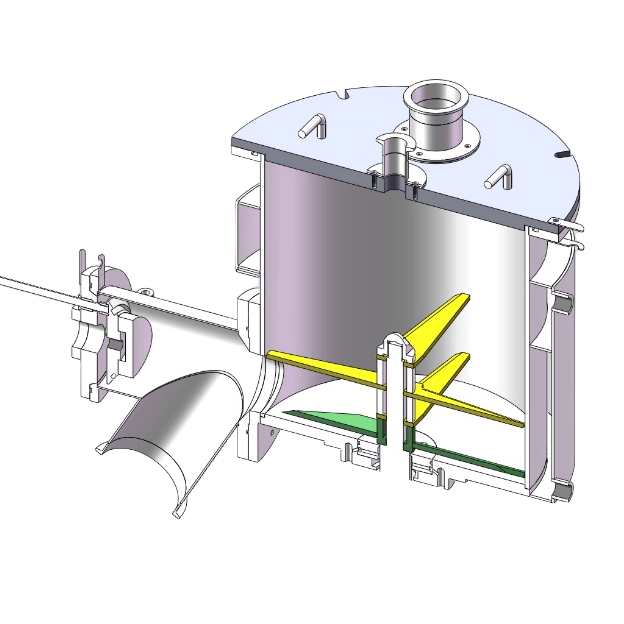

The TSG series high-speed mixing granulator utilizes the vortex airflow generated by high-speed rotor rotation to achieve forced mixing. One process can achieve dispersion, mixing, coating, and granulation. During the process of pelletizing, it ensures the compactness and uniform shape of the sphere, which is not easy to cause shape damage. It can be used for mixing and granulation of dry electrodes.

Ⅱ、Technical principles

When the bottom flipping blade of the mixing tank rotates, a parabolic airflow is generated from the center to the surrounding area. At the same time, the blade rotation and groove wall also generate a curved airflow. The two airflow interact to cause the powder in the tank to rotate and be evenly dispersed, mixed, and combined with the use of binders, achieving the function of coating granulation.

Ⅲ、Features

1) A device simultaneously has functions of dispersion, mixing, mixing, granulation, and coating.

2) Spherical granulation that can correspond to ultrafine powders (nanoscale) up to several millimeters (several um to several millimeters)

3) Achieve functions such as dispersion, mixing, stirring, and granulation in a short period of time.

4) Combined with the use of adhesives, it can be used for powder coating and liquid film coating.

5) There are no unnecessary obstacles in the granulation tank, and there is less adhesion of raw materials, enabling the powder to achieve ideal three-dimensional movement.

6) The device has strong convenience in operation and is easy to use without any threshold. Combined with a controllable PLC control system, the device can be freely and flexibly regulated,

|

Model |

Size of granulation tank (diameter * height mm) |

Full capacity(L) |

Power(kw) |

|

LITH-TSG-200 |

100*300 |

5 |

2.2 |

Ⅳ、Remarks

Excluding electrical installation, foundation work, primary electrical work, compressed air equipment, and related pipeline installation work outside of the system.

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588