- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

TMAX-DRY-CY05MOQ :

1Warranty:

2yearsDelivery Time:

5 days

Dry Electrode Laboratory/Pilot/Production Line /Technology and Preparation Key Solution

Ⅰ、The main differences between dry electrode batteries and traditional batteries in electrode technology:

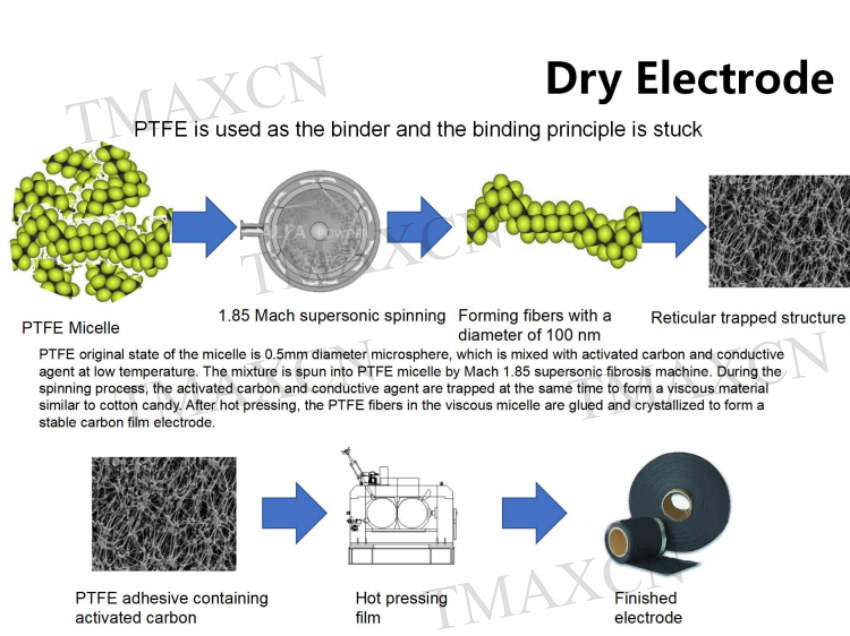

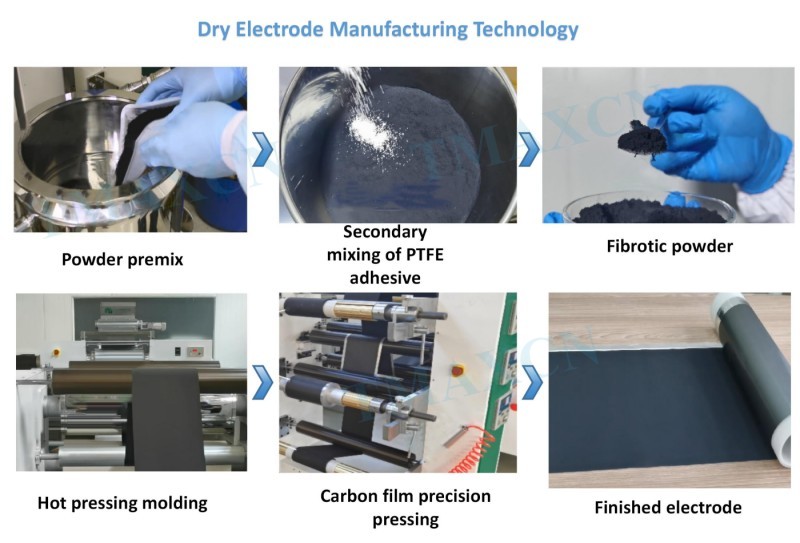

The difference between dry electrode batteries and traditional batteries is mainly reflected in the manufacturing process of the electrode plates. Traditional lithium battery manufacturing involves mixing solvent NMP with negative or positive electrode powder with adhesive materials, then coating the slurry on the electrode collector and drying it. Dry electrode technology does not use solvents, but mixes a small amount (about 5-8%) of fine powder PTFE adhesive with positive electrode powder, and then forms a thin electrode material strip through an extruder. Finally, the extruded electrode material strip is laminated onto a metal foil collector to form a finished electrode.

1) High compaction density makes it more compatible with high nickel battery material systems.

The current battery material system of high nickel positive electrode+silicon carbon negative electrode is one of the mainstream directions for the development of lithium batteries.

In terms of positive electrodes, under the traditional production conditions of lithium batteries, high nickel positive electrodes have poor thermal stability, unstable surface structure, and nickel elements are alkaline and easily absorb moisture. The use of dry electrodes can effectively alleviate the above problems.

2) The cost is reduced by more than 10% -20% compared to wet processes.

Dry electrodes do not use toxic NMP solvents, making them more environmentally friendly. At the same time, production processes such as coating and electrode drying are eliminated, reducing material and equipment costs and simplifying production processes.

3) Improvement of other important performance.

This includes longer cycle life (twice that of wet processes), better high-temperature stability, higher charging and discharging rates (lower internal resistance of dry electrode plates), and lower energy consumption.

II、Introduction of Dry Electrode

III、Process Flow Chart

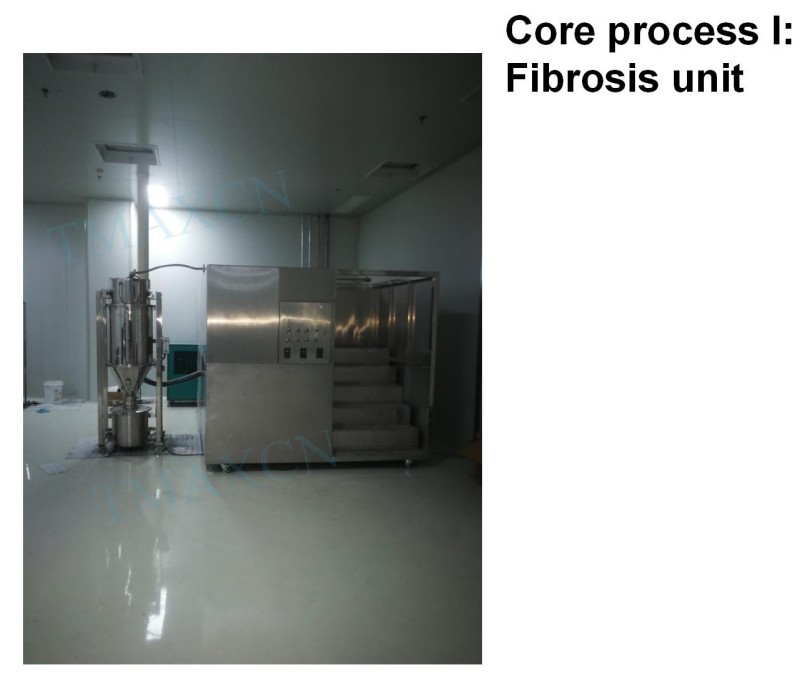

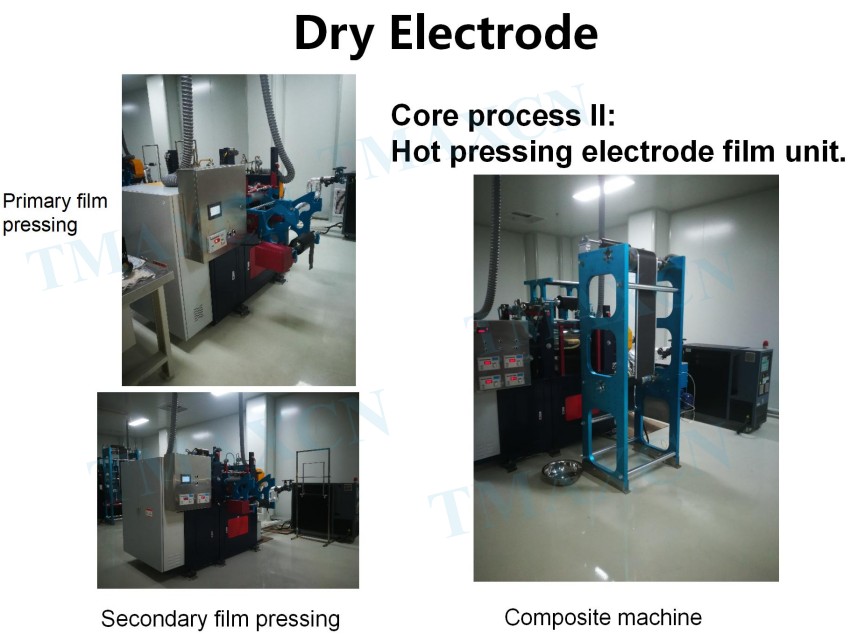

IV、Core Technological processes

V、Finished Electrode

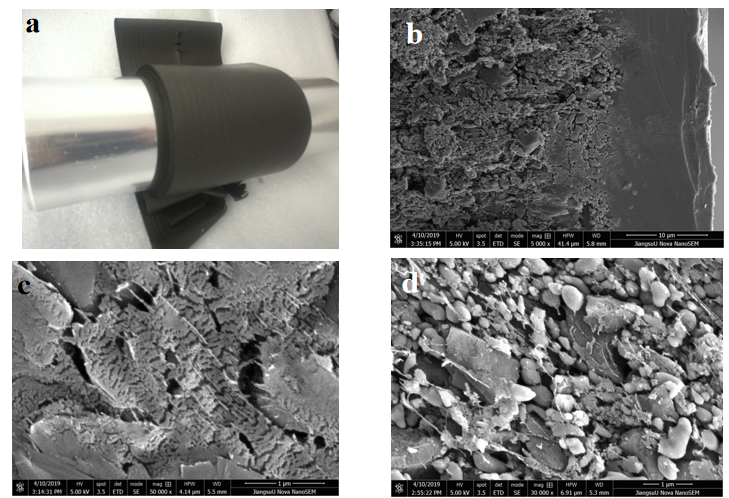

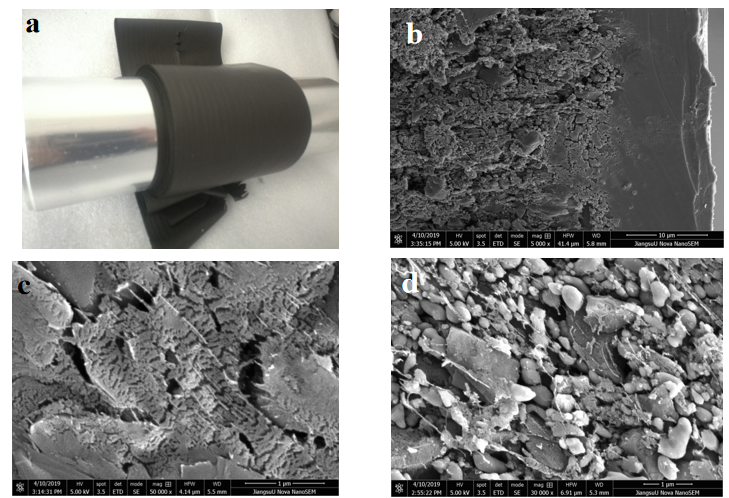

Fig (a) Self supporting film of dry electrode sheet.

(b) SEM cross section of lithium iron phosphate dry process electrode.

(c) SEM image of the surface of lithium iron phosphate dry electrode, PTFE particles are bonded together after fibrosis.

(d) SEM of PTFE fibrosis on the surface of graphite dry electrode.

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588