ItemNo :

LITH-XFT750AMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

High-Performance Electrode Slitting Machine for Lithium-Ion Battery Production

The automatic electrode slitting machine is mainly used for slitting lithium-ion battery electrodes. It is a mature and stable model independently developed by our company for mainstream slitting processes in the market. The machine supports a slitting width range of 10–680 mm and is easy to operate, meeting diverse slitting requirements. It adopts a double-shaft rewinding structure. The electrode material is mounted on the unwinding shaft, passively unwound via the drive roller, automatically aligned, and then passes through the slitting knives and dust removal brushes to complete the slitting process as per process requirements. The machine is user-friendly, with simple loading and threading, stable performance, and good slitting results.

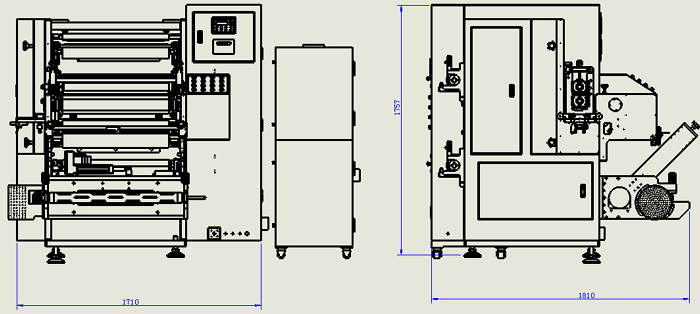

· Overall dimensions (L×W×H): approx. 1810 × 1710 × 1757 mm

|

Component |

Description |

|

Unwinding Shaft |

3-inch air expanding shaft (9+1 lug bladder) |

|

Max Unwind Ø |

450 mm |

|

Guiding Control |

Manual/Auto mode switch |

|

Guiding System |

Photoelectric web guide, ±50 mm stroke, ±0.1 mm accuracy |

|

Tension System |

High-sensitivity tension sensor + unwind brake with PLC for closed-loop tension control |

|

Tension Accuracy |

±2 N |

|

Splicing Platform |

Chrome-plated surface with threading grooves; double pressure bars with pneumatic clamping |

|

Component |

Description |

|

Knife Unit |

Adjustable gap between top and bottom knives (via spacer replacement); adjustable engagement depth |

|

Speed Display |

Upper/lower knife line speed ratio shown on HMI |

|

Spacer Design |

Precision spacers of different widths ensure consistent slitting width |

|

Knife Guide Rollers |

Infeed rollers installed on the knife frame |

|

Drive Method |

Top and bottom knives driven independently by servo motors |

|

Component |

Description |

|

Rewind Shaft |

Two sets of Φ3″ (ID Φ76.2 mm) differential shafts (core provided by customer) |

|

Max Rewind Ø |

450 mm |

|

Tracking Rollers |

One set per rewind shaft to adapt to roll diameter variation |

|

Component |

Description |

|

Knife Dust Collection |

Bottom knife equipped with dust removal device |

|

Electrode Dust Collection |

One set each for upper and lower electrodes post-slit |

|

Component |

Description |

|

Upper Belt |

Pneumatic roller controlled by solenoid valve to press the upper electrode during rewinding |

|

Lower Belt |

Pneumatic roller controlled by solenoid valve to press the lower electrode during rewinding |

|

Component |

Description |

|

Upper Arm |

Pneumatically controlled pressure arm with chrome-plated roller |

|

Lower Arm |

Pneumatically controlled pressure arm with chrome-plated roller |

|

Component |

Description |

|

Rewind Drive |

Motor drives upper and lower rewind shafts via synchronous belt/pulley system |

|

Traction Drive |

Motor drives traction and transition rollers via synchronous belt/pulley system |

|

Section |

Description |

|

Unwind Control |

Controls web guiding and splicing table pressure rods |

|

Rewind Control |

Main control section with touchscreen interface |

|

Section |

Description |

|

Unwinding Tension |

Controls tension during unwinding |

|

Post-slit Tension |

Open-loop control of tension after slitting |

|

Name |

Brand |

Origin |

|

PLC |

Panasonic |

Japan |

|

HMI Screen |

Konlyon Tongtai |

Taiwan, China |

|

Tension Control System |

Aibo / KRD |

China |

|

Tension Sensor |

Aibo / KRD |

China |

|

Magnetic Powder Clutch |

Kejia |

China |

|

Rewind Motor |

Geared Motor |

China |

|

Main Drive Motor |

Geared Motor |

China |

|

Pneumatic Solenoid Valve |

AIRTAC |

Taiwan, China |

|

Cylinder |

AIRTAC |

Taiwan, China |

|

Proportional Valve |

SMC |

Japan |

|

Rotary Encoder |

OMRON |

Japan |

|

Power Protection Circuit Breaker |

Chint/NXB-63 3P |

China |

|

Linear Guide Rails |

HIWIN |

Taiwan, China |

|

Bearings |

NSK / Havaro / Imported |

Japan / China / Imported |

|

Differential Shaft |

|

China |

|

Dust Collector System |

|

China |

|

Knife Cart |

XHL-1000 (self-made) |

China |

|

Knife Holder |

|

China |

2.1 Incoming Material Specifications

|

Roll diameter |

max Φ450 mm |

|

Roll weight |

max 320 kg |

|

Core inner diameter |

Φ3″ (Φ76.2 mm) |

|

Foil width |

max 680 mm |

|

Foil thickness |

copper 4.5–20 μm; aluminum 9–25 μm |

|

Coated material max width |

max 650 mm |

|

Slitted electrode thickness |

50–200 μm |

Please provide the following information to match proper tooling and optimize slitting results:

a. Material type: LFP / NCM / LCO / sodium-based cathode, graphite / hard-carbon anode

b. Material thickness: 0.05–0.2 μm

c. Tensile strength: ≥30 kgf/mm²

d. Narrowest and widest roll width: 330–680 mm

e. Narrowest and widest slit widths: 15–207 mm

These parameters are essential for proper tool selection—please pay attention.

|

Item |

Specification |

|

Unwinding Shaft |

3-inch air expanding shaft |

|

Maximum Unwinding Diameter |

Max φ450mm |

|

Web Feeding Method |

Manual threading |

|

Unwinding Tension Control |

Automatic closed-loop tension control system |

|

Tension Control Range and Accuracy |

20–200N, ±2N |

|

Slitting Method |

Multi-strip simultaneous rotary disc cutting |

|

Rewinding Method |

Dual upper and lower slip shaft rewinding units |

|

Slip Shaft |

Low-friction slip shaft (#14) |

|

EPC Controller Stroke and Accuracy |

±50mm, ±0.1mm |

|

Mechanical Speed |

Max 50m/min (continuously adjustable) |

|

Slitting Acceptance Speed |

10–18mm: 20m/min; Above 18mm: 30–50m/min |

|

Minimum Slitting Width |

10mm |

|

Slitting Width Accuracy |

±0.05mm (Edge trim width ≥2mm, fully coated) |

|

Knife Holder Configuration |

Two combined knife holders: one configured with a full set of spacers for 25-strip slitting (with knife holders and blades), and the other with 26 knife holders only. (Note: Customer’s universal spacers of the same specification are compatible with this machine’s fixed spacers.) |

|

Knife Holder Transfer Cart |

One provided per machine |

|

Dust Collection |

Dust collection at material receiving platform, knife holder, and both sides of slit electrodes (requires brush roller structure). Integrated into customer’s central dust collection system. Interface reserved: φ90mm |

|

Demagnetization Configuration |

Equipped with four rectangular magnets (10,000 Gauss) post-slitting. Adjustable spacing between 3–15mm |

|

Pressure Roller Configuration |

Standard: 25 sets/machine. Model: L20×40mm. Compatible with equipment from this factory |

|

Slitting Knife Brand |

Domestic alloy blade, φ100mm disc bladeMinimum usable diameter: φ96mmSupplied blade shim thicknesses: 9.8mm / 9.55mm / 9.3mm / 9.05mm / 8.8mm / 8.55mm / 8.3mm |

|

Electrode Burrs (Including Coating and Foil) |

Longitudinal burrs ≤5μm (measured vertically beyond the coating); Lateral burrs ≤7μm (measured horizontally beyond the coating). Incoming materials must be free of removable slurry or visible serration. |

|

Electrode Serpentine Deviation (Slitting Direction Curvature) |

Test method: Lay the sheet flat. Fix both ends aligned to a 1-meter ruler. Use a transparent ruler to measure max distance between sheet and ruler: ≤±0.3mm/1000mm. Must ensure good post-calendering flatness, no deformation, sufficient edge trim, no powder loss, no waviness, no stretching, no cracking. |

|

Electrode Edge Waviness |

Test method: Lay flat, measure using optical instrument: ≤±0.5mm. Must meet same quality standards as above. |

|

Intelligent Counting Features |

Total slitting length, unwind/rewind tension, upper/lower slit speed ratio, friction coefficient, blade life, machine speed, total meters slit, runtime—all adjustable via touchscreen |

|

Electrical Requirements |

3-phase, 5-wire, 380V / 30A / 50Hz |

|

Air Consumption |

150L/min |

|

Total Power |

Approx. 8kW; compressed air pressure >5kg/cm² |

|

Air Quality Requirements |

Water-free, oil-free, filtered clean air |

|

Operating Environment |

Temperature: 20–40°C; Humidity: 30–70% |

|

Rewinding Width |

Min 10mm – Max 680mm (using slip shaft #14) |

|

Rewinding End Face Alignment Accuracy |

±0.5mm |

|

Rewinding Tension Control Range |

Per shaft: 5–50N |

|

Edge Trim Handling |

Trim width: 3–5mm (must be fully coated material) |

|

Machine Utilization Rate |

≥95% |

|

Machine Weight |

Approx. 3.5T (Customer floor bearing capacity: 600kg/m²) |

|

Machine Color |

Frame and electrical cabinet in warm gray; other parts chromed (custom colors require customer-provided color sample) |

|

Accessories Supplied |

Chinese user manual, maintenance manual, and manuals for purchased components |

|

Noise Level |

≤80 dB measured 1m from winding area (excluding material-related noises like tape peeling) |

|

Note |

Customer must provide one roll of electrode sheet (approx. 500m, as applicable for positive/negative) for machine testing |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975