- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ZW-D300MOQ :

1Color :

optionalPort :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

5 daysDouble Sides Automatic Numerical Control Spot Welding Machine for Battery Pack for EV Bike Battery

Application

It is suitable for electric vehicle battery pack, automobile battery module, street lamp battery, balance car battery pack, scooter battery pack, mobile power supply, startup battery pack module, power tool battery pack, notebook battery pack, etc!

Features

1. Support breakpoint start, support automatic start and manual start mode conversion.

2. Simple programming, support any point programming and array programming, can realize jump spot

welding, single point, double point mode fast switching, spot welding path optimization, improve efficiency, local disk can store 99 groups of programming files, USB interface can import graphics.

3. The spot welding head takes the center point of two welding pins as the circle center, and the angle is continuously adjustable, which is suitable for spot welding of various special-shaped split connection pieces.

4. The system is divided into operator, administrator, super user and so on. It is convenient to use, manage and maintain butt welding machine.

5. The inverter DC welding power supply has the advantages of stable performance, fast welding speed, constant current working mode and elimination of unstable factors of welding current for a long time.

6. With welding current monitoring system, it can monitor welding current in real time.

7. Spot welding power supply has the function of false welding alarm, which can directly communicate with the motion controller. It can record the false welding position and warn the replacement of welding pin.

8. The welding efficiency is about 8 times that of manual welding, high stability, labor saving and time cost saving.

Specifications

|

Power supply |

3 phase~380V±10%/50Hz±10%, |

|

Rated power |

50KW(max) |

|

Z1,Z2 Travel Length |

0-600mm(max) |

|

Y Travel Length |

0-1200mm(max) |

|

X Travel Length |

0-40mm |

|

W Shaft angle |

0 |

|

Welding speed |

0.35 S/point;1800-3600PCS/h |

|

Maximum speed of motor transmission |

1500mm/s |

|

Maximum load cell (32650) |

512 pcs |

|

Number of file groups that can be stored |

99 |

|

operating system |

Industrial computer + man machine picture |

|

Transmission mode |

Servo motor + TBI screw + linear guide rail |

|

Spindle electrode |

Letron servo motor |

|

Spot welding head |

Letron servo motor |

|

Angle adjustment |

Closed loop motor |

|

Cooling mode |

forced air cooling |

|

Nickel sheet material |

Nickel plated steel or pure nickel |

|

Thickness of Welded Nickel Strip |

0.1 mm-0.3 mm; (above 0.2 mm slot with bump) |

|

External dimension (mm) |

1800L*1100W*2000H |

|

Repeat positioning accuracy |

±0.02mm |

|

Weight |

600kg |

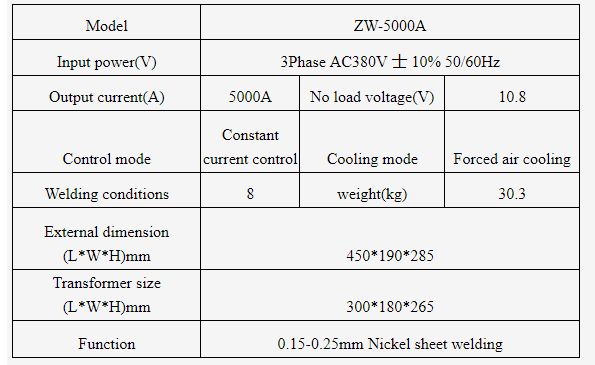

Technical parameters

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588