ItemNo :

LITH-CCS1100MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

2 daysEmail :

Louis@lithmachine.comCylindrical Battery In-Situ Volume Swelling Testing System

Characteristic

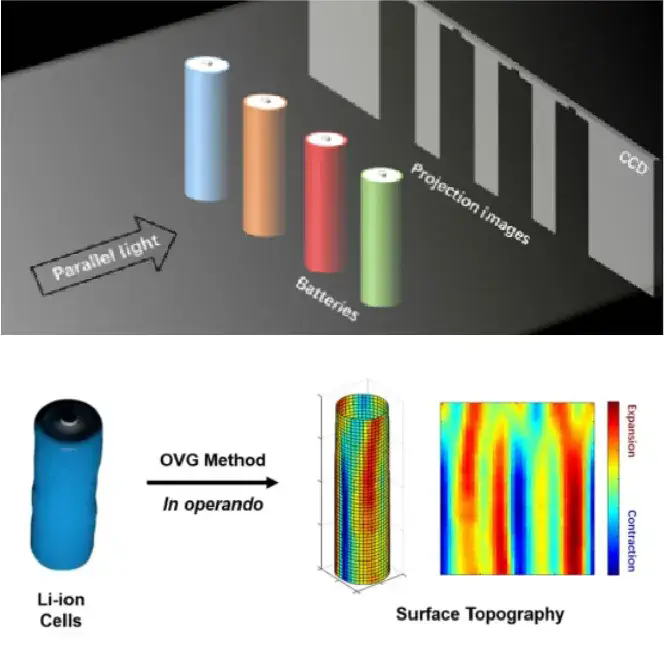

1. Optical lmaging+ 3D Reconstruction + Real-time Online Monitoring

2. Non-contact, Non-destructive

3. High-throughput testing, suitable for mass production

4. Real time reconstruction of battery surface morphology and calculation of volumedeformation during charge and discharge processes.

5. Combining voltage and current data todetect and predict battery health condition from a higher dimension.

Applications

1. Material evaluation

2. Structural evaluation

3. Evaluation of different working conditions such as temperature, rate, storage, etc.

Description

1. Significance of Volume Swelling Testing for Cylindrical Battery

Significance: During the charge and discharge processes of lithium ion batteries, as lithium ions intercalate and deintercalate into the positive and negative electrode materials, the cell undergoes reversible expansion and contraction. Concurrently, various side reactions occur, such as particle fracture, SEI membrane rupture, cell deformation, lithium plating, gas evolution, etc., resulting in irreversible deformation.

Limitations of Existing Methods: Curently, there are several methods available to characterize the expansion of cylindrical batteries, such as vernier calipers cordinate measuring machines, presure fims, strain gauges, and imaging analysis technigues (including CT scanning, neutron imaing, X-ray, ultrasound etc.) However, these methods suer from low accuracy, inability to conduct in-situ testing, and inability to acurately and comprehensively describe the expansion behavior of cylindrical batteries.

Application Scenarios: Material evaluation, evaluation ofthe modification results of silicon anode, high-nickel ternary, lithium-rich manganese-based and other materials used in cylindrical batteries; structural evaluation, evaluation of cylindrical battery core structures of different sizes, rolled core structures. and shell rupture risk assessment; Working condition evaluation, evaluation of working conditions at different temperatures, charge/discharge rate, storage, etc.

2. Product Features

1) Opticallmaging+ 3D Reconstruction + Real-time Online Monitoring

2) Non-contact, Non-destructive

3) High-throughput testing, suitable for mass production

Real-time reconstruction of battery surface morphology and calculation of volume deformation during charge and discharge processes. Combining voltage and current data todetect and predict battery health condition from a higher dimension.

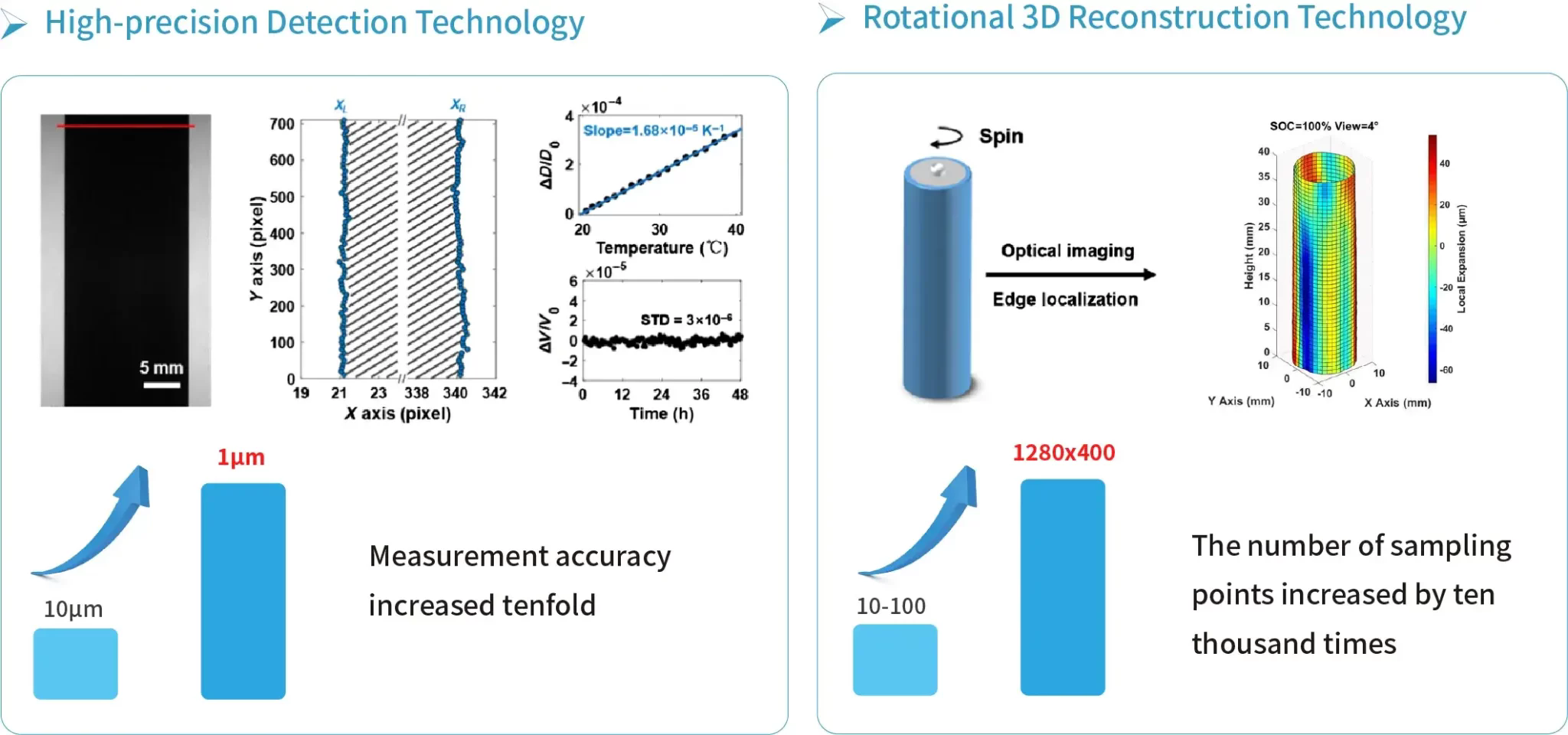

3. Leading Technology

Application Cases

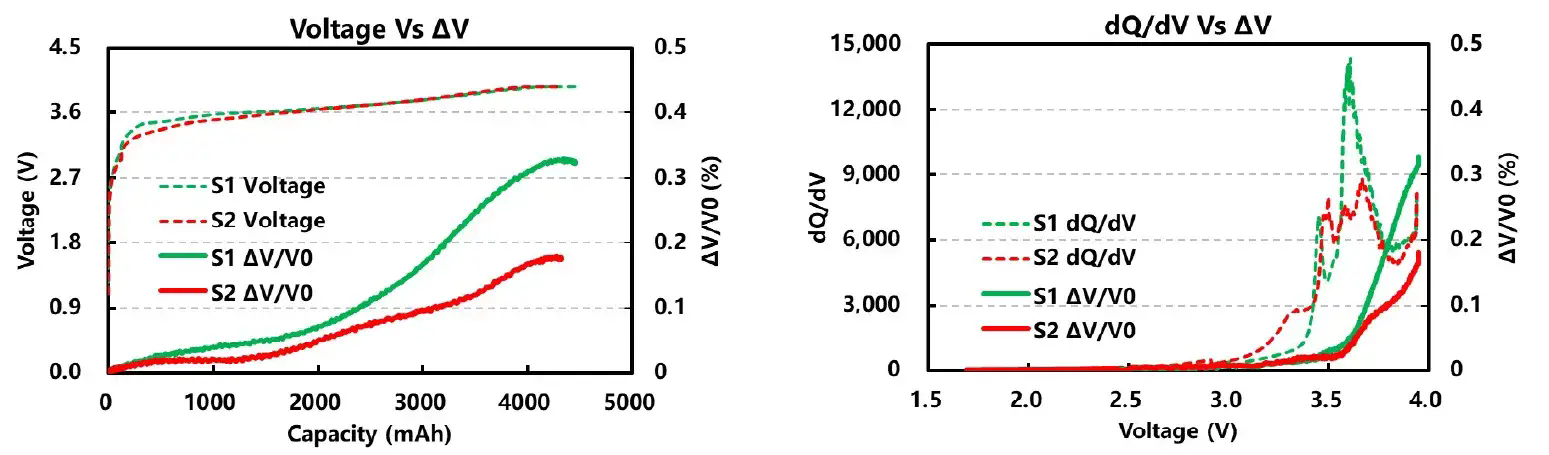

Swelling Testing of cells with Different Silicon Contents

21700 Cell parameters: Sample 1-15%Sic ; Sample 2-10%Sic

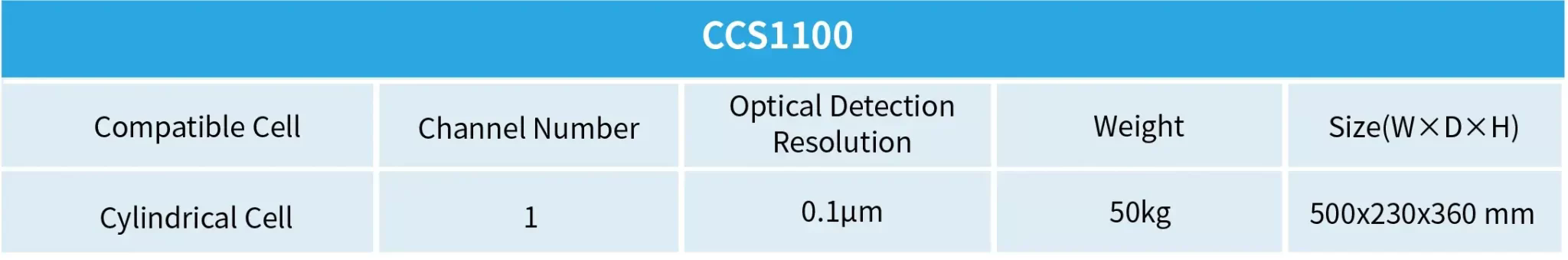

Specifications

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME: 15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975