- Language:

English ▼

English ▼

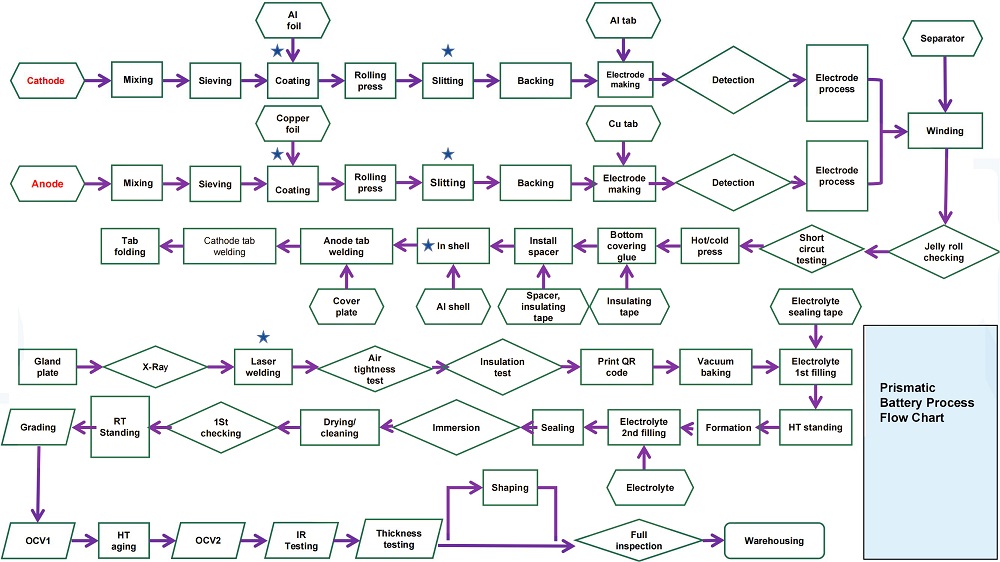

Prismatic battery manufacturing line offer several advantages and technological strengths, making them a preferred choice for producing rechargeable batteries in various applications. Here are some of the key advantages and technological strengths associated with prismatic battery manufacturing:

Uniform Shape and Size: Prismatic cells are manufactured with precise dimensions and uniformity. This consistency in size and shape simplifies the design and assembly of battery packs, making them easier to integrate into products.

Stackability: Prismatic cells are designed for efficient stacking, allowing manufacturers to build battery packs with different voltage and capacity requirements. This stackability enhances flexibility in designing battery modules and packs.

Efficient Space Utilization: The rectangular shape of prismatic cells allows for efficient space utilization in battery packs. This is essential for applications like EVs, where battery space must be optimized for vehicle design and performance.

Enhanced Thermal Management: Prismatic cells can incorporate advanced thermal management systems more easily due to their flat and stackable design. Effective thermal management helps maintain optimal operating temperatures, improving battery safety and longevity.

Ease of Handling: Prismatic cells are easier to handle during manufacturing, assembly, and installation compared to other cell formats like cylindrical cells. This reduces the risk of damage and errors during production.

Automated Production: Prismatic battery manufacturing plants are often highly automated, enabling efficient and consistent production processes. Automation helps reduce labor costs and enhances product quality.

Customizable Designs: Manufacturers can customize the shape, size, and capacity of prismatic cells to meet specific product requirements. This versatility is valuable for various applications.

Quality Control: Prismatic cells can undergo rigorous quality control and testing processes, ensuring that only cells meeting performance and safety standards are used in battery packs.

Traceability: Each prismatic cell can be labeled with a unique identifier, enabling traceability throughout the manufacturing process and product lifecycle.

Safety Features: Prismatic cells can incorporate safety features such as venting mechanisms and protection circuits to minimize the risk of thermal runaway and overcharging.

Environmental Considerations: Prismatic cell manufacturing line can implement environmentally friendly practices, including recycling and responsible disposal of old or defective batteries.

High Energy Efficiency: Prismatic cells are designed for high energy efficiency, making them suitable for applications that require longer operating times between charges.

Overall, prismatic battery pilot plant leverage the advantages of prismatic cell design to produce batteries that meet the demands of various industries for energy storage, transportation, and consumer electronics. These technological strengths contribute to the widespread adoption of prismatic cells in the market.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588