- Language:

English ▼

English ▼

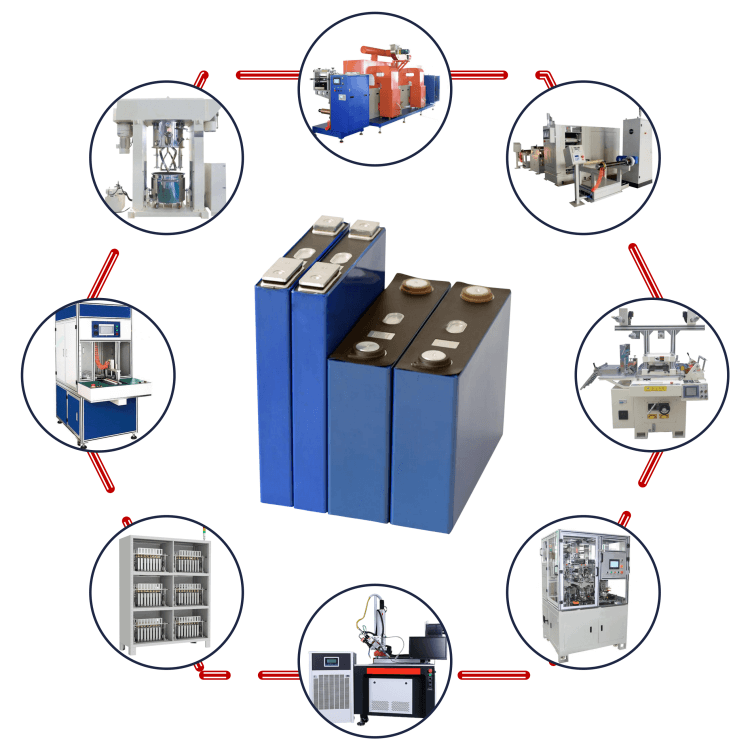

Prismatic cell assembly plant offer several production advantages due to their specialized manufacturing processes and technologies. These advantages make them an efficient choice for producing prismatic lithium-ion battery cells for various applications. Here are some of the production advantages of prismatic battery assembly plants:

High Energy Density: Prismatic battery cells often have a higher energy density compared to other cell types, allowing for more energy storage in a compact space. This is advantageous for applications requiring long-lasting power in a limited form factor.

Space Efficiency: Prismatic cells have a flat and rectangular shape, allowing for efficient use of space within battery packs and modules. This design optimizes packing density and space utilization.

Ease of Stacking: The flat shape of prismatic cells enables easy stacking of multiple cells to achieve the desired voltage and capacity, reducing complexity in module and pack assembly.

Automated Manufacturing: Prismatic battery production plant are equipped with advanced automation and robotics, leading to efficient and consistent cell assembly, which reduces labor costs and enhances production speed.

Consistent Performance: Prismatic cells are manufactured with precision, resulting in uniform electrode coatings and separator placement, leading to consistent cell performance across batches.

Design Flexibility: Manufacturers can tailor prismatic cells to meet specific voltage, capacity, and form factor requirements for different applications, offering design flexibility to meet diverse market needs.

Integration into Product Design: Prismatic cells can be easily integrated into various product designs due to their flat shape and consistent dimensions, making them suitable for a wide range of applications.

Improved Thermal Management: Prismatic cells facilitate effective thermal management systems, as the flat design allows for even heat distribution and efficient cooling solutions, contributing to longer battery life and enhanced safety.

Quality Control: The automated nature of prismatic cell manufacturing line enables rigorous quality control measures, resulting in higher product quality and reliability.

Environmental Considerations: Prismatic battery assembly plants can implement environmentally friendly practices, such as using sustainable materials and recycling processes, reducing their environmental footprint.

Safety: Prismatic cells are less prone to swelling compared to cylindrical cells, enhancing safety by reducing the risk of physical damage and internal short circuits.

Market Acceptance: Prismatic cells have gained wide acceptance in electric vehicle production due to their efficiency, safety, and compatibility with automotive assembly processes.

Customization: Manufacturers can customize prismatic cells to meet specific industry and application requirements, ensuring compatibility and performance.

Overall, prismatic battery assembly plants leverage advanced technologies and production processes to produce high-quality, reliable, and efficient lithium-ion battery cells that meet the demands of various industries, including automotive, consumer electronics, and renewable energy systems.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588