Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Ceramic Sintering Furnace: A Comprehensive Technical Introduction

A ceramic sintering furnace is a highly specialized thermal-processing system designed to densify, strengthen, and stabilize ceramic materials through precisely controlled high-temperature treatment. As advanced ceramics continue to play a strategic role in electronics, energy systems, biomedical devices, aerospace components, and structural engineering, the ceramic sintering furnace has become one of the most essential pieces of equipment in both research laboratories and industrial manufacturing environments. Its ability to deliver uniform heating, accurate temperature profiles, and repeatable results ensures that ceramic materials achieve the microstructural and functional properties required for high-performance applications.

Overview

The ceramic sintering furnace is engineered to heat ceramic green bodies—powders, pressed compacts, tapes, or molded shapes—to temperatures typically ranging from 800°C to over 1800°C, depending on the material system. During the sintering process, particles bond together, porosity is reduced, and the ceramic achieves its final density and mechanical integrity. Modern furnaces support a range of atmospheres, including air, inert gas, vacuum, reducing environments, or mixed-gas atmospheres, enabling precise tuning of material properties such as grain growth, conductivity, and phase composition.

These furnaces are widely integrated into the production workflows of advanced ceramics such as alumina, zirconia, silicon carbide, silicon nitride, ferrites, piezoelectric ceramics, and solid-state electrolyte materials used in next-generation batteries.

Key Features

A high-quality ceramic sintering furnace is characterized by several essential engineering features:

1. High-Temperature Capability

Many industrial models operate above 1600°C, incorporating high-grade insulation materials and heating elements such as MoSi₂, SiC rods, graphite elements, or tungsten heaters depending on temperature requirements.

2. Uniform Temperature Distribution

Multi-zone temperature control ensures homogenous heating throughout the chamber. Uniformity is critical for avoiding thermal gradients that can cause cracking, warping, or uneven densification.

3. Programmable Temperature Control

Advanced PID controllers and multi-step programs allow precise ramp-up, soaking, and cooling profiles tailored to specific ceramic formulations.

4. Atmosphere Control

Gas inlet systems, vacuum pumps, and sealed chambers allow processing under oxygen-controlled or inert environments, essential for preventing oxidation or facilitating reduction reactions.

5. Robust Thermal Insulation

Fiberboard, alumina refractory materials, or carbon insulation systems minimize heat loss, improve energy efficiency, and provide stability at extreme temperatures.

6. Safety & Automation Features

Interlocks, over-temperature protection, and automated cooling enhance operational safety, especially during long sintering cycles.

Sintering Process

The sintering process within a ceramic sintering furnace generally follows a sequence of carefully controlled thermal steps:

1. Initial Heating

The furnace raises the temperature gradually to eliminate residual solvents and binders. A controlled ramp rate prevents thermal shock.

2. Intermediate Stage

Particle surfaces begin to diffuse and bond. Porosity decreases, and the structure begins to consolidate.

3. High-Temperature Soaking

At peak sintering temperature, the material undergoes intense atomic diffusion, densification, and grain growth. Mechanical strength and final microstructure are formed during this critical stage.

4. Controlled Cooling

Cooling profiles are equally important. Slow, uniform cooling prevents internal stress buildup and helps maintain dimensional stability.

The precise shaping of these thermal steps is essential to producing ceramics with consistent density, electrical behavior, and mechanical performance.

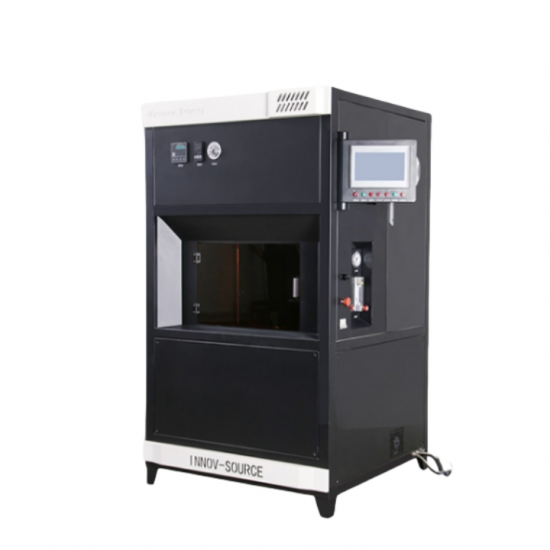

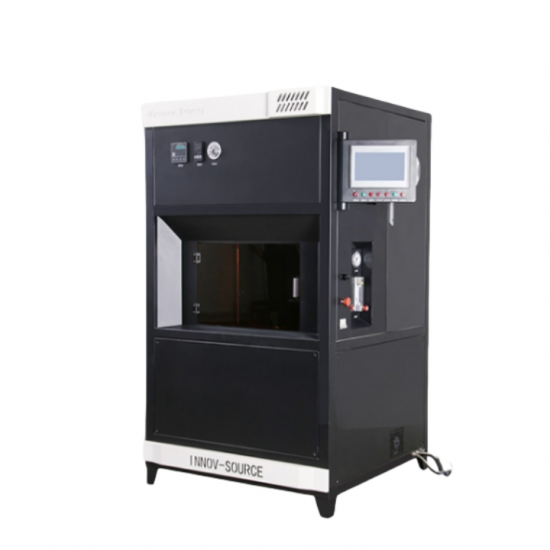

Atmosphere Sintering Furnace

Applications

Ceramic sintering furnaces serve a broad spectrum of industries:

* Electronic Ceramics

Production of MLCC dielectric layers, ferrites, piezoelectric components, LTCC/HTCC substrates, and semiconductor packaging materials.

* Energy Storage Materials

Sintering of solid-state electrolyte ceramics (LLZO, LATP, LAGP), cathode materials, and ceramic separators for advanced batteries.

* Aerospace and Defense

Manufacturing of ultra-high-temperature ceramics such as ZrB₂, HfC, SiC composites, and structural ceramic parts.

* Biomedical Ceramics

Processing of dental zirconia, hydroxyapatite implants, and other bioceramics requiring absolute purity and density.

* Industrial Ceramics

Wear-resistant components, cutting tools, filtration membranes, and engineered ceramic parts for high-stress environments.

Advantages

A ceramic sintering furnace offers several important advantages:

1. High Precision and Repeatability

Temperature uniformity and advanced process control lead to highly consistent material quality.

2. Versatility

Suitable for a wide variety of ceramic materials and sintering atmospheres.

3. Energy Efficiency

Modern insulation and heating systems reduce power consumption during long high-temperature cycles.

4. Scalability

Systems range from benchtop laboratory units to large industrial continuous-sintering furnaces.

5. Enhanced Material Performance

Proper sintering improves density, strength, electrical characteristics, and thermal stability of ceramic products.

English ▼

English ▼ English ▼

English ▼

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588