Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Carbon Foam Battery: A Comprehensive Guide

A carbon foam battery is an advanced energy storage technology that leverages the unique properties of carbon foam as a key component. Carbon foam, characterized by its lightweight, porous structure, offers excellent electrical conductivity, thermal management, and mechanical strength. These attributes make it an ideal material for enhancing the performance of batteries, particularly in applications requiring high power density and fast charging capabilities.

Below is an indepth exploration of carbon foam batteries, including their composition, advantages, challenges, applications, and future potential.

●1. What Is a Carbon Foam Battery?

A carbon foam battery integrates carbon foam into its design, typically as part of the electrode or separator structure. The porous nature of carbon foam provides a large surface area for electrochemical reactions, improving the efficiency and capacity of the battery. This innovation addresses some of the limitations of traditional lithiumion and other battery chemistries, such as slow charging times and limited cycle life.

●2. Composition of Carbon Foam Batteries

Key Components

1. Carbon Foam Electrodes:

Made from carbon aerogels, graphene foams, or activated carbon.

Provide a highsurfacearea substrate for active materials like lithium or other ions.

2. Electrolyte:

Can be liquid, gel, or solidstate, depending on the battery type.

Facilitates ion movement between electrodes during charge/discharge cycles.

3. Separator:

Often made from carbon foam or coated with it to enhance thermal stability and prevent short circuits.

4. Current Collectors:

Lightweight and conductive materials ensure efficient electron transfer.

●3. Advantages of Carbon Foam Batteries

1. High Power Density:

The porous structure of carbon foam allows for rapid ion transport, enabling faster charging and discharging.

2. Improved Thermal Management:

Carbon foam's excellent thermal conductivity helps dissipate heat, reducing the risk of overheating and thermal runaway.

3. Enhanced Cycle Life:

The robust mechanical properties of carbon foam reduce degradation over time, leading to longer battery lifespans.

4. Lightweight Design:

Carbon foam's low density contributes to lighter batteries, making them suitable for portable and aerospace applications.

5. Environmental Benefits:

Carbon foam can be derived from renewable or recycled sources, promoting sustainability.

●4. Challenges of Carbon Foam Batteries

Despite their promise, carbon foam batteries face several challenges:

1. Manufacturing Complexity:

Producing highquality carbon foam at scale is technically challenging and expensive.

2. Cost:

Advanced materials and processing techniques increase production costs compared to conventional batteries.

3. Limited Commercial Availability:

Carbon foam batteries are still in the research and development phase for many applications.

4. Compatibility Issues:

Integrating carbon foam with existing battery chemistries may require significant modifications to cell designs.

●5. Applications of Carbon Foam Batteries

A. Electric Vehicles (EVs)

Carbon foam batteries offer higher power density and faster charging, addressing key limitations of current EV batteries.

B. Portable Electronics

Lightweight and compact design makes them ideal for smartphones, laptops, and wearable devices.

C. Aerospace and Defense

Superior thermal management and durability make them suitable for satellites, drones, and military equipment.

D. Renewable Energy Storage

High cycle life and efficiency enable effective integration with solar and wind energy systems.

E. Medical Devices

Compact size and long lifespan support applications like implantable devices and portable diagnostic tools.

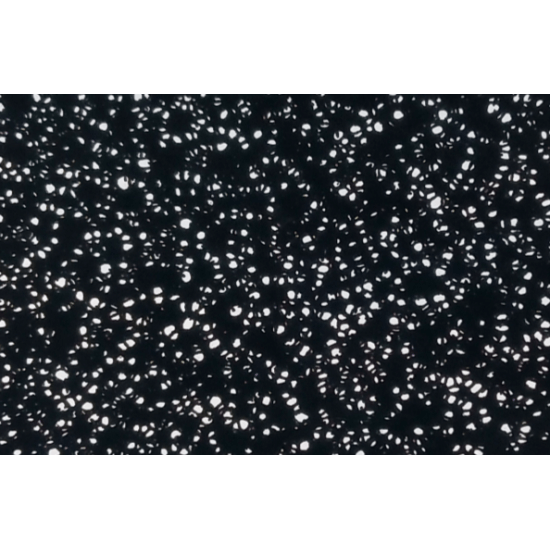

Electrode Carbon Foam

●6. How Carbon Foam Enhances Battery Performance

| Aspect | Traditional Batteries | Carbon Foam Batteries |

||||

| Surface Area | Limited by electrode geometry | Increased due to porous carbon foam structure |

| Charging Speed | Slower due to ion diffusion limitations | Faster due to enhanced ion transport |

| Thermal Stability | Prone to overheating in highpower applications | Improved heat dissipation via carbon foam |

| Cycle Life | Degradation occurs over time | Reduced degradation thanks to durable foam |

| Weight | Heavier materials limit portability | Lightweight carbon foam reduces overall weight |

●7. Manufacturing Process of Carbon Foam Batteries

The production of carbon foam batteries involves several steps:

1. Synthesis of Carbon Foam:

Precursor materials (e.g., resins, polymers) are processed into a porous structure through techniques like pyrolysis or chemical vapor deposition.

2. Coating with Active Materials:

The carbon foam is coated with lithium compounds, nickel, manganese, or other active materials to form the electrode.

3. Assembly:

The carbon foam electrodes, electrolyte, and separator are assembled into a complete battery cell.

4. Testing and Optimization:

Cells undergo rigorous testing to evaluate performance, safety, and longevity.

●8. Current Research and Development

Researchers are actively exploring ways to improve carbon foam batteries, focusing on:

1. Material Innovations:

Developing new types of carbon foam with enhanced properties, such as higher conductivity or larger surface areas.

2. Processing Techniques:

Simplifying and scaling up manufacturing methods to reduce costs.

3. Hybrid Systems:

Combining carbon foam with other advanced materials, such as silicon or metal oxides, to boost performance.

4. SolidState Integration:

Incorporating carbon foam into solidstate batteries to achieve safer and more efficient energy storage.

●9. Future Trends in Carbon Foam Batteries

1. Increased Adoption:

As manufacturing costs decrease, carbon foam batteries are expected to gain traction in various industries.

2. Higher Energy Density:

Advances in material science will enable batteries with even greater energy storage capabilities.

3. Sustainability Focus:

Efforts to develop ecofriendly carbon foam from renewable resources will promote greener battery technologies.

4. Integration with Smart Systems:

Carbon foam batteries may incorporate IoT and AI for realtime monitoring and optimization.

●10. Conclusion

Carbon foam batteries represent a promising advancement in energy storage technology, offering improved performance, safety, and sustainability. While challenges remain in terms of cost and scalability, ongoing research and development are paving the way for their widespread adoption. As demand for highperformance batteries grows across industries, carbon foam batteries could play a pivotal role in shaping the future of energy storage.

If you're interested in learning more about specific aspects of carbon foam batteries or their potential applications, feel free to ask!

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588