Assisting clients in establishing a

car battery fabrication plant involves providing the following support and advice:

Market Research and Business Planning:

Assisting clients with comprehensive market research to understand current and future trends, demands, and competition in the car battery market.

Collaborating on the development of a robust business plan, including identifying target markets, product positioning, production scale, and sales strategies.

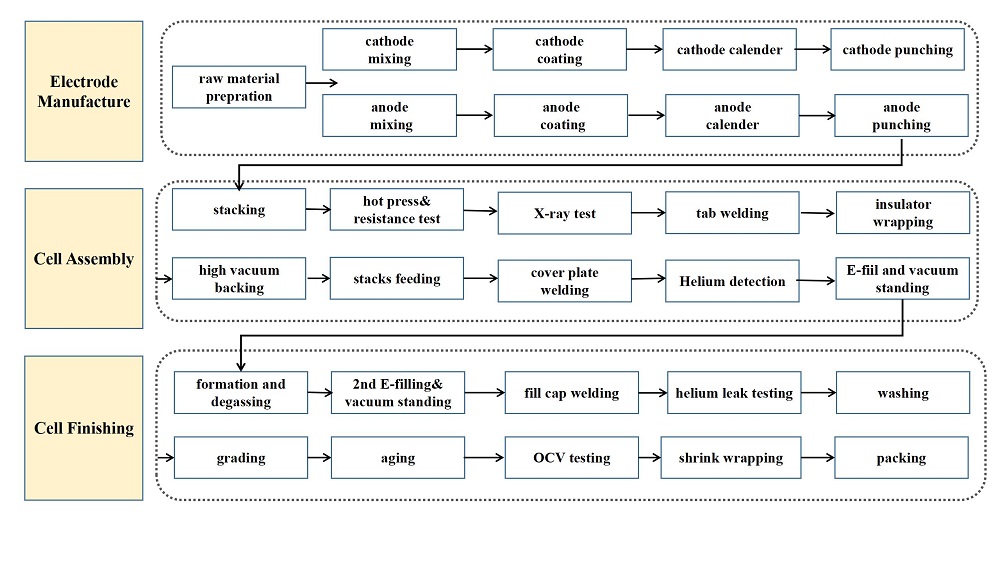

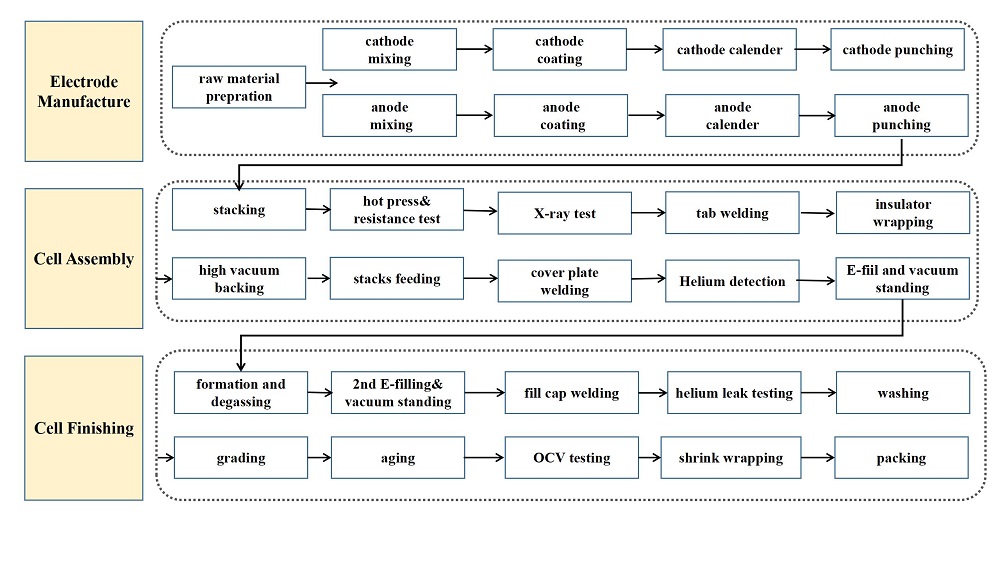

Factory Layout and Equipment Configuration:

Providing guidance on factory layout design to ensure efficient production processes and operational safety based on the client's needs and anticipated capacity.

Assisting clients in selecting appropriate equipment and machinery to meet production requirements, including electrode preparation equipment, battery assembly lines, and quality inspection equipment.

Technical Consultation and Training:

Offering technical consultation and professional advice on car battery manufacturing, including the latest production processes, material selection, and quality control standards.

Providing training programs for staff, covering production operation skills, quality control procedures, and safety regulations.

Quality Control and Certification Support:

Assisting clients in establishing a comprehensive quality management system, including setting quality inspection standards, implementing testing procedures, and corrective measures.

Providing support for certification processes to help clients obtain relevant quality certifications, such as ISO 9001 and TS 16949.

Supply Chain Management and Material Selection:

Assisting clients in establishing a stable supply chain to ensure timely and quality-controlled delivery of raw materials.

Offering advice on material selection and procurement, helping clients choose suitable electrode materials, electrolytes, and other critical components.

Operational Efficiency and Continuous Improvement:

Analyzing production processes and providing improvement suggestions to enhance production efficiency, reduce costs, and optimize resource utilization.

Guiding clients in implementing continuous improvement plans, including establishing performance indicators, conducting data analysis, and driving process optimization.

We can provide various suggestions for production lines, including Prismatic battery production line, Pouch Cell Lab line, and Cylindrical Cell Lab line. You can contact customer service.

Marketing and Sales Support:

Assisting clients in developing marketing and sales strategies, including brand promotion, market positioning, and channel development.

Providing marketing materials and sales tools to help clients promote their products and services and expand market share.

Compliance and Regulatory Assistance:

Offering guidance on regulatory compliance requirements related to car battery manufacturing, ensuring clients adhere to relevant safety, environmental, and industry regulations.

By providing comprehensive support and expertise, we aim to empower clients in successfully establishing their car battery fabrication plant and positioning themselves for success in the dynamic automotive industry.

English ▼

English ▼ Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588