An In-Depth Exploration of

Car Battery Production Line

Introduction:

In the dynamic landscape of automotive electrification, car battery production lines are instrumental in propelling the widespread adoption of electric and hybrid vehicles. These sophisticated manufacturing systems integrate advanced technologies, stringent quality control measures, and a focus on sustainability. In this in-depth research blog, we will delve into the intricate workings of car battery production lines, examining their key components, operational considerations, and the transformative impact they have on the automotive industry.

Optimized Production Process:

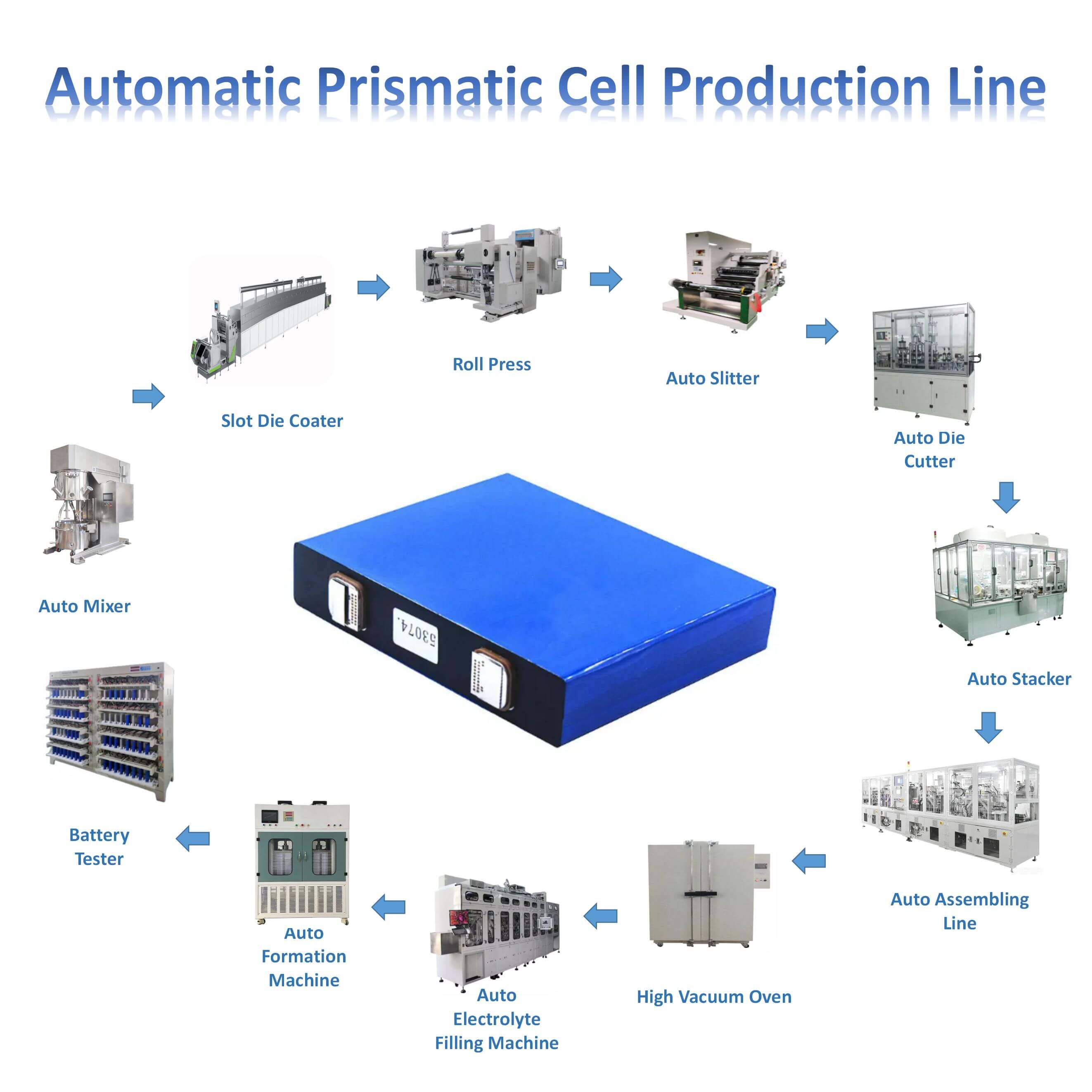

Car battery production lines are meticulously designed to streamline the manufacturing process and maximize efficiency. These lines encompass multiple stages, including electrode fabrication, Ultrasonic Metal Spot Welder, battery stacking machine, battery die cutter, cell assembly, module integration, and pack assembly. Each stage involves a range of specialized equipment, such as electrode coating machines, automated cell stackers, precision welding systems, and advanced testing apparatus. This optimized production process ensures the seamless integration of various components to deliver high-quality and reliable car batteries.

Advanced Battery Technologies:

Car battery production lines leverage cutting-edge battery technologies to meet the growing demands of the automotive industry. These technologies include advanced electrode materials, such as lithium-ion and solid-state electrolytes, that offer enhanced energy density, improved safety features, and longer lifespan. The production lines also incorporate innovative cell designs, thermal management systems, and intelligent battery management systems (BMS) to optimize performance, charging efficiency, and overall reliability.

Quality Assurance and Testing:

Ensuring the highest level of quality and performance is a top priority for car battery production lines. Rigorous quality control measures are implemented throughout the manufacturing process, encompassing material inspection, process validation, and final product testing. Advanced testing equipment, such as comprehensive battery analyzers, impedance spectroscopy systems, and environmental testing chambers, enable thorough evaluation of battery characteristics, performance, and safety parameters. These stringent quality assurance practices guarantee the delivery of reliable and durable car batteries to meet stringent industry standards.

Scalability and Flexibility:

Car battery production lines are designed to be scalable and flexible to adapt to evolving market needs. Manufacturers can easily scale up production capacity to meet increasing demand or modify the production line configuration to accommodate different battery chemistries, sizes, and form factors. This flexibility enables manufacturers to cater to diverse customer requirements, support various vehicle models, and explore new battery technologies and designs. By embracing scalability and flexibility, production lines drive innovation and facilitate the rapid growth of the electric vehicle market.

Sustainability and Environmental Impact:

Environmental sustainability is a core consideration in car battery production lines. Manufacturers prioritize the adoption of eco-friendly practices and technologies to minimize the environmental impact of battery production. This includes implementing recycling programs for battery components, reducing energy consumption through optimized processes, and utilizing renewable energy sources whenever possible. By promoting sustainability throughout the production process, car battery production lines contribute to the overall goal of reducing carbon emissions and creating a greener transportation ecosystem.

Conclusion:

Car battery production lines are the backbone of the automotive industry's electrification journey. These advanced systems combine state-of-the-art technologies, rigorous quality control measures, and a commitment to sustainability to deliver high-performance and reliable car batteries. By continuously pushing the boundaries of battery technology and optimizing production processes, these production lines are driving the widespread adoption of electric and hybrid vehicles. As the demand for cleaner and more sustainable transportation continues to grow, car battery production lines will play a pivotal role in shaping the future of automotive electrification and fostering a greener and more efficient mobility ecosystem.

English ▼

English ▼ English ▼

English ▼ ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588