- Language:

English ▼

English ▼

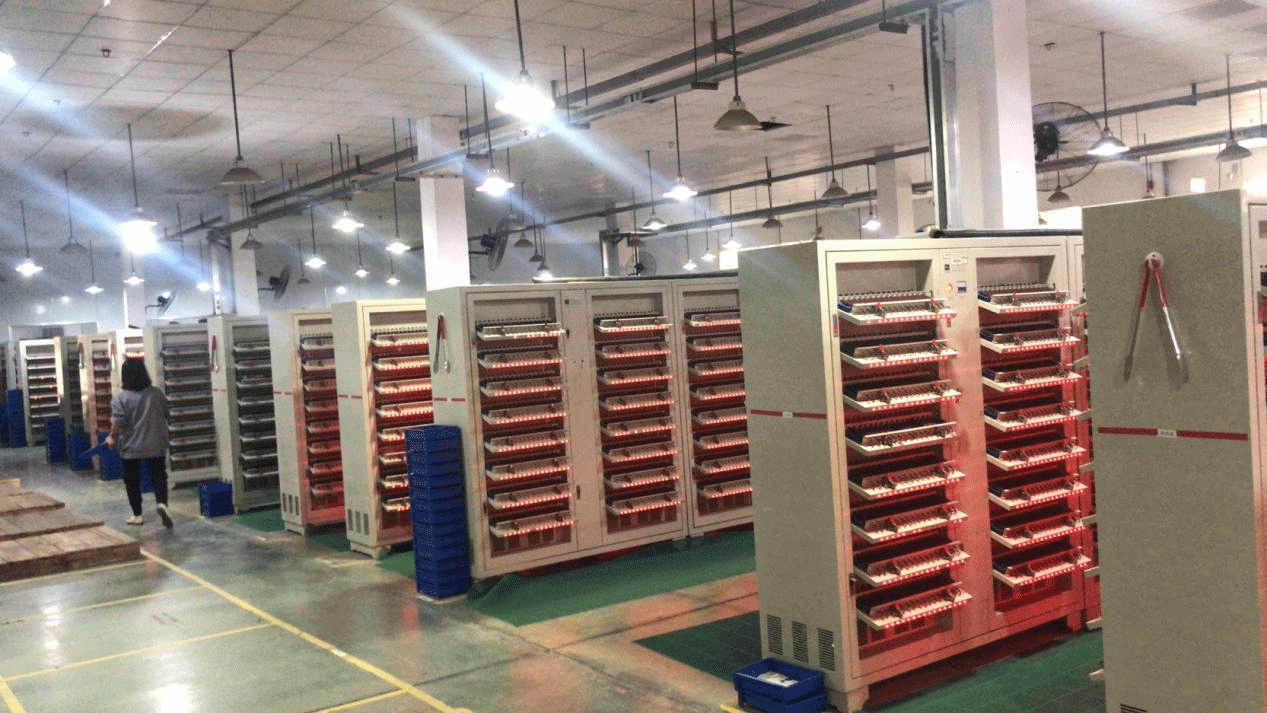

Battery Pack Assembly equipment is a highly automated system designed for the mass production of battery packs. It consists of a series of processing stations that handle specific assembly steps. These stations are typically arranged in a linear or circular configuration, and the packs move from one station to the next on a conveyor or other automated system.

The first processing station is the battery sorting machine. In this station, battery cells are sorted and grouped according to their specifications, including voltage, capacity, and internal resistance. The sorting process ensures that all the cells in the pack have similar performance characteristics.

The next station is the cell tab welding station. Here, the tabs made of nickel or other conductive material are welded to the terminals of each cell. The tabs serve as electrical contacts and provide a secure mechanical connection between the cells.

The third processing station is the insulation station. Here, the cells are covered with insulating material, such as polyethylene foam or a dielectric film, to prevent electrical contact between the cells. The insulation also helps to protect the cells from physical damage.

The fourth processing station is the stacking station. In this station, the cells are arranged in the desired configuration, typically in a series or parallel arrangement, to achieve the desired voltage and capacity. The cells are then placed in a pack enclosure, which can be made of plastic, metal, or other materials.

The fifth processing station is the sealing station. Here, the pack enclosure is sealed using a heat sealing process, adhesive, or other means. The completed battery pack is then tested for quality and performance using a variety of tests, such as electrical performance, environmental durability, and safety testing.

Battery Pack Assembly plant are highly flexible and can be configured to produce a wide range of battery pack sizes and configurations. They are commonly used in the production of battery packs for electric vehicles, portable electronics, and grid energy storage systems. The machines are capable of producing battery packs with high accuracy and consistency, which is essential for ensuring the reliability and safety of the final product.

No. 5 Nanshan Road, Huli District, Xiamen City, Fujian Province, China

Subscribe to us

Subscribe to us ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588