Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Automatic Film Applicator: A Comprehensive Guide

An automatic film applicator is a machine designed to apply films (such as shrink wrap, protective coatings, or adhesive films) onto products, packages, or surfaces in an automated and efficient manner. These machines are widely used in industries like packaging, manufacturing, automotive, electronics, and construction for tasks such as wrapping, sealing, protecting, or decorating.

Below is a detailed overview of automatic film applicators, including their types, components, applications, advantages, and pricing.

●1. What Is an Automatic Film Applicator?

An automatic film applicator is a device that automates the process of applying films onto objects or surfaces. It eliminates manual labor, reduces errors, and ensures consistent application. The machine typically handles various types of films, such as:

Shrink Films: Used for packaging.

Adhesive Films: For bonding or labeling.

Protective Films: To shield surfaces from scratches or damage.

Decorative Films: For aesthetic purposes.

The applicator can be programmed to apply films uniformly, ensuring precision and efficiency.

●2. Types of Automatic Film Applicators

A. By Film Type

1. Shrink Wrap Applicators:

Designed for applying heatshrinkable films around products or packages.

Commonly used in packaging operations.

2. Adhesive Film Applicators:

Apply pressuresensitive adhesive films for bonding or labeling.

Used in industries like automotive and electronics.

3. Protective Film Applicators:

Apply transparent or colored films to protect surfaces during transportation or storage.

Common in construction and manufacturing.

4. Decorative Film Applicators:

Used for applying films with patterns, textures, or colors for aesthetic enhancement.

Popular in interior design and product decoration.

B. By Application Method

1. RolltoRoll Applicators:

Suitable for continuous film application on large surfaces.

Ideal for industries like textiles, laminates, and solar panels.

2. Spot Applicators:

Apply films to specific areas or spots on a surface.

Used for targeted protection or decoration.

3. WrapAround Applicators:

Wrap films completely around objects or packages.

Common in packaging and logistics.

●3. Components of an Automatic Film Applicator

1. Film Roll Holder:

Secures the film roll and feeds it into the system.

2. Dispensing Mechanism:

Controls the speed and tension of the film as it is applied.

3. Cutting System:

Cuts the film to the desired length after application.

4. Alignment System:

Ensures precise placement of the film on the target surface.

5. Heating Element (for Shrink Films):

Shrinks the film to fit snugly around the object.

6. Control Panel:

Allows operators to program settings such as speed, tension, and film type.

7. Conveyor System:

Moves objects through the applicator in automated setups.

●4. Applications of Automatic Film Applicators

A. Packaging Industry

Wrapping products for shipment.

Applying protective films to fragile items.

Sealing cartons or pallets with shrink wrap.

B. Automotive Industry

Applying protective films to car exteriors during transport.

Bonding windshields or other glass components.

C. Electronics Industry

Applying adhesive films for component assembly.

Protecting sensitive parts during manufacturing.

D. Construction Industry

Applying weatherproofing films to building materials.

Protecting surfaces during renovation or painting.

E. Retail and Display

Decorating products with branded films.

Applying antitheft or tamperevident films.

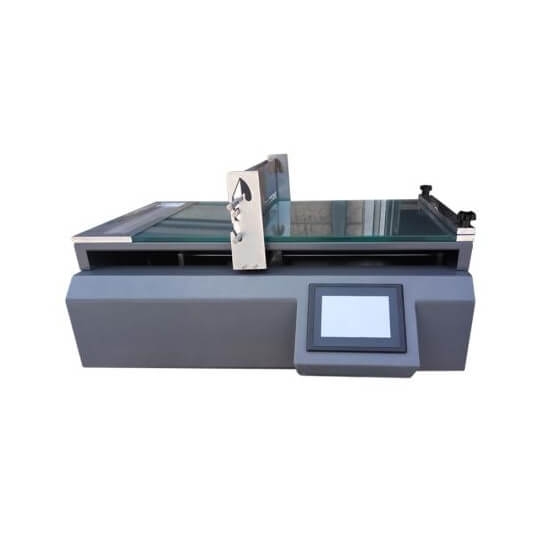

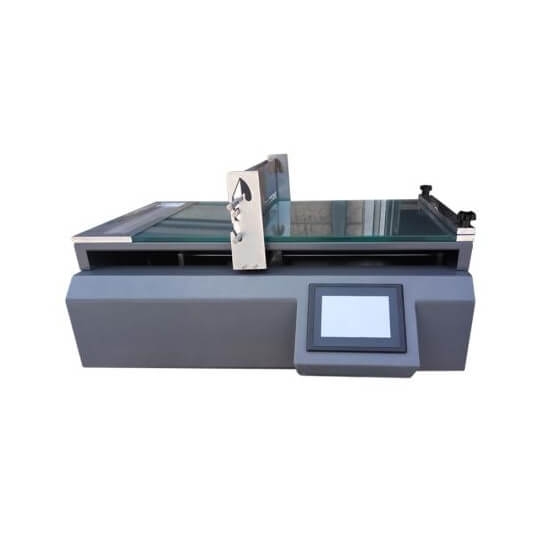

Film Coating Machine

●5. Advantages of Automatic Film Applicators

1. Increased Efficiency:

Automates repetitive tasks, reducing labor costs and improving throughput.

2. Consistency:

Ensures uniform application of films, minimizing errors.

3. Cost Savings:

Reduces material waste by optimizing film usage.

4. Safety:

Minimizes human exposure to hazardous materials or sharp edges.

5. Flexibility:

Can handle various film types and substrates with minimal adjustments.

●6. Limitations of Automatic Film Applicators

1. High Initial Cost:

Investment in machinery can be significant, especially for advanced models.

2. Maintenance Requirements:

Regular upkeep is necessary to ensure optimal performance.

3. Complexity:

Some systems require specialized training for operation and programming.

4. Limited Customization:

Standard machines may not accommodate unique or irregular shapes without customization.

●7. Pricing of Automatic Film Applicators

The cost of an automatic film applicator depends on factors such as size, complexity, features, and brand. Below are approximate price ranges:

| Type | Price Range |

|||

| Basic Models | $5,000–$15,000 |

| MidRange Models | $15,000–$50,000 |

| HighEnd Models | $50,000–$200,000+ |

Factors Influencing Price

1. Automation Level: Fully automated systems are more expensive than semiautomated ones.

2. Film Handling Capability: Machines capable of handling multiple film types or thicknesses cost more.

3. Custom Features: Addons like advanced sensors, heating elements, or conveyor systems increase the price.

4. Brand and Quality: Reputable brands often charge a premium for reliability and support.

●8. Future Trends in Automatic Film Applicators

1. Smart Technology Integration:

Incorporation of IoT, AI, and machine learning for predictive maintenance and realtime monitoring.

2. Sustainability:

Development of ecofriendly films and energyefficient applicators.

3. Compact Designs:

Smaller, modular systems for spaceconstrained environments.

4. Enhanced Precision:

Improved alignment and cutting systems for better accuracy.

●9. Conclusion

Automatic film applicators are essential tools for industries requiring efficient and precise film application. Their ability to automate repetitive tasks, reduce costs, and improve quality makes them indispensable in modern manufacturing and packaging processes.

If you're considering investing in an automatic film applicator, evaluating your specific needs, budget, and longterm goals will help you choose the right system. Let me know if you'd like further details or guidance!

English ▼

English ▼ English ▼

English ▼

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588