- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-YC-FXJ08-FMOQ :

1Port :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

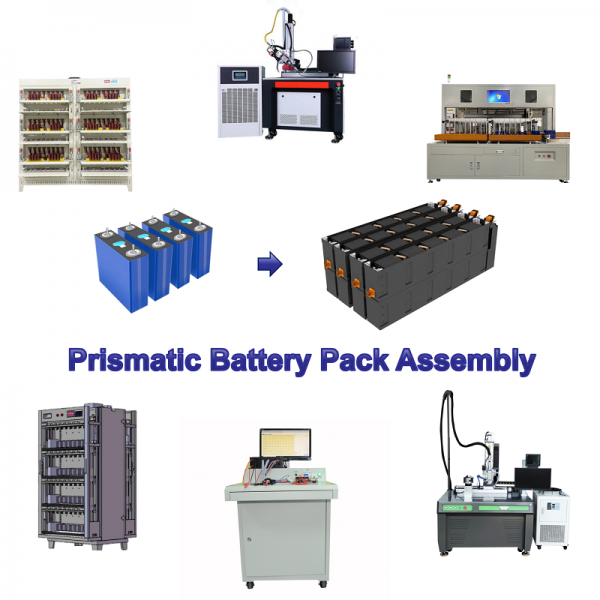

5 days8 Channel Prismatic Cell Sorting Machine Automatic ACIR Tester

I. Equipment functional characteristics:

*The equipment includes brand computer, software system, precision voltage internal resistance measuring instrument, code scanning mechanism, batch loading device, automatic grading of manipulator, automatic blanking and other devices.

*According to the AC internal resistance, open circuit voltage and other parameters of lithium batteries, the batteries are accurately graded and grouped according to various performance parameters. The maximum number of graded pairs at one time is 8, which improves the consistency of pack battery quality and paired cell performance.

*AC internal resistance and open circuit voltage can be collected automatically by using the built-in high-precision internal resistance meter BT3562A. The sorting process is automatically controlled. It is simple to operate, and manual participation is abandoned. This ensures the accuracy of test parameters and the reliability of the pairing process, and improves and guarantees the performance and quality of pack products.

*High degree of automation, simple operation, hopper feeding, simple operation, about 600 electric cores can be tested and assembled per hour, which can effectively improve production efficiency and reduce production costs.

*The performance data of the electric core tested by the system shall be managed by the database, which shall be kept for a long time with strong traceability. Cooperate with the data analysis function of the software to conduct long-term monitoring and analysis on product performance and quality to guide the improvement of R&D formula and production process.

*The industrial control computer collects the data and automatically generates the curve chart and bar chart. The system has the database function, which can trace the historical data and export it.

II. Applicable battery specifications and incoming material requirements

1. Square 50 * 160 * 118, 36 * 130 * 200, 30 * 130 * 200 batteries;

2. The positive and negative electrodes are clean and free of dirt.

III. Description of equipment technical parameters:

*Power supply: 220V, 0.5KW.

*Air source: 0.5 ~ 0.6 Mpa (dry air).

*Separation efficiency: ≥ 10PPM.

*Product qualification rate: ≥ 99%.

*Standby rate: ≥ 95%.

*Qualified rate of sorting: ≥ 98%.

*Sorting accuracy: 99.9%.

*Secondary test: edge gear voltage deviation ± 0.1mV, internal resistance deviation ± 0.05m Ω.

*Sorting parameters: open circuit voltage, AC internal resistance.

*Instrument: precision voltage internal resistance tester.

*Equipment weight: ≥ 300KG.

*Overall dimension: 1600 (L) *1600 (W)* 1700 (H) mm.

IV. The equipment includes the following modules:

*Model: LITH-YC-FXJ08-F test sorting system, which can complete the testing and sorting pairing of conventional open circuit voltage and AC internal resistance.

*One set of HIOKI BT3562A internal resistance meter is installed daily to test the AC internal resistance and open circuit voltage.

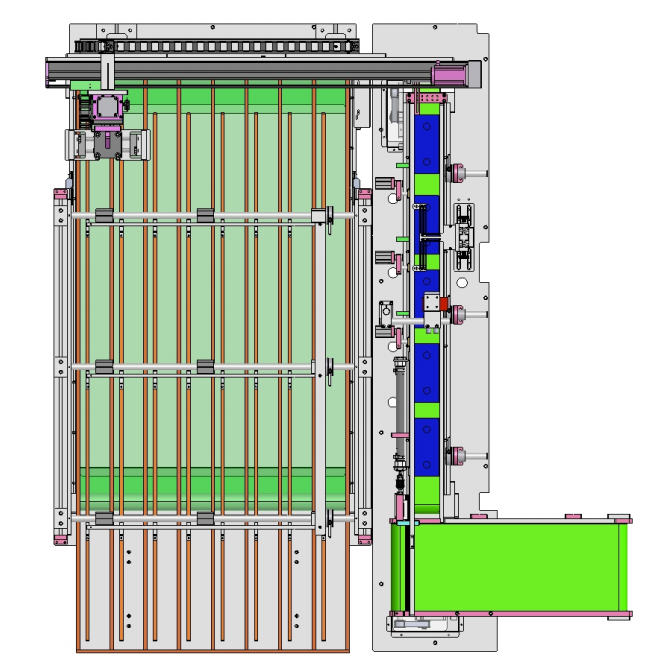

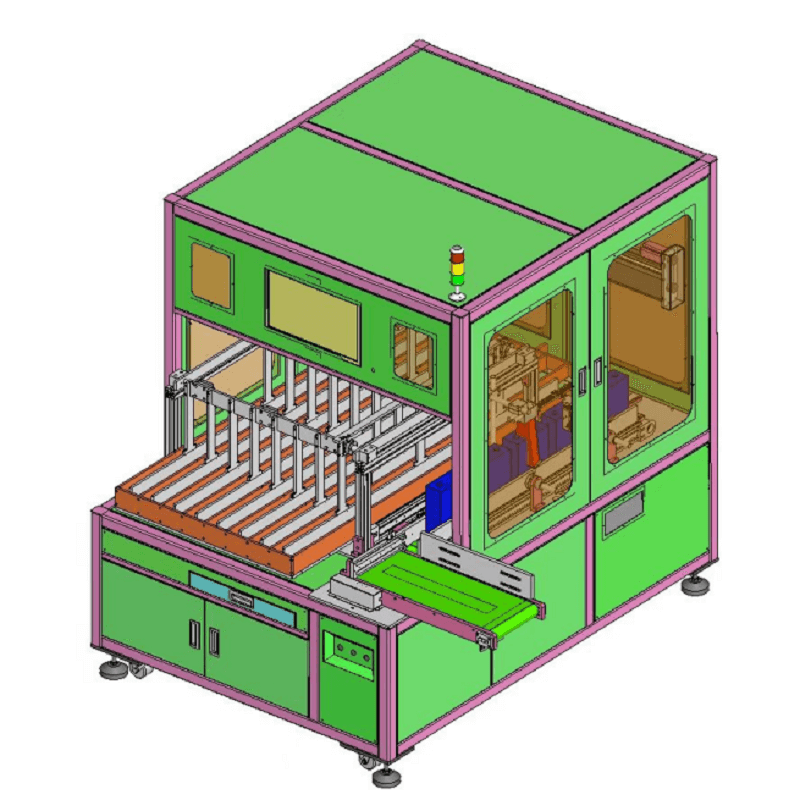

V. Equipment layout:

VI. Equipment configuration list:

|

Series Number |

Configure |

Brand |

|

1 |

Cylinder |

AIRTAC |

|

2 |

Solenoid valve |

AIRTAC |

|

3 |

Linear guide rail |

HIWIN |

|

4 |

Relay |

OMRON |

|

5 |

Motion control card |

Rexay Intelligence |

|

6 |

A sensor |

Jiazhun |

|

7 |

Computer host |

Yanyue IPC |

|

8 |

Test instrument |

HIOKI BT3562A |

|

9 |

Software system |

Battery automatic testing and sorting system |

VII. Other requirements:

The probe is a wearing part with spring, and its service life is related to the test frequency. If the test frequency is very high, it is generally recommended that the customer replace the probe within 30 days, and evaluate it according to the specific usage. The probe is more convenient and simple. It only takes 3-5 minutes. At the same time, our company will deliver certain vulnerable parts to the user company.

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588