- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-PC-103MOQ :

1Port :

Xiamen PortCompliance:

CEWarranty:

2 yearsDelivery Time:

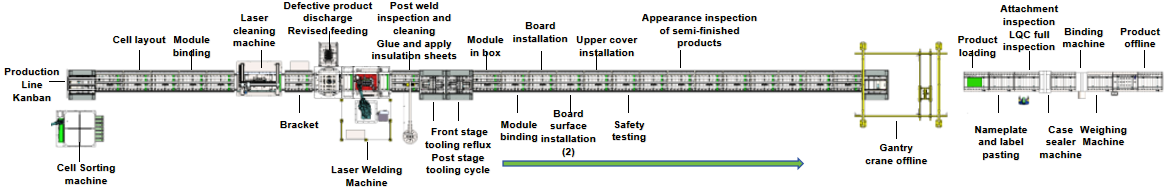

5 daysAutomated Production Line for Prismatic Lithium Battery Packs

Product Introduction

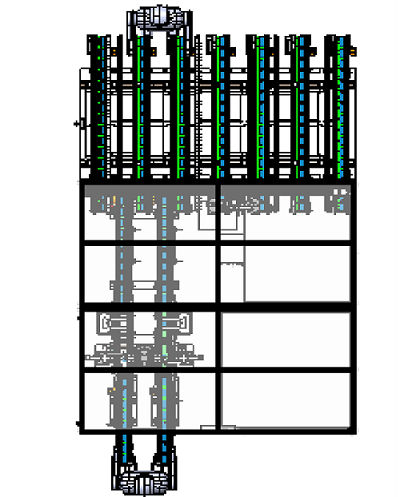

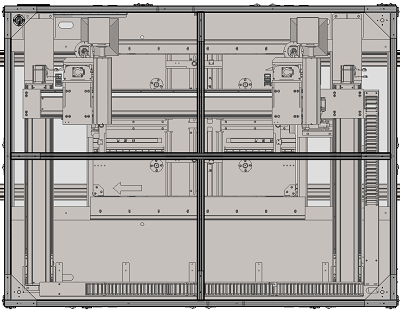

This production line is used for the automation production of square shell battery modules and PACK. The main equipment includes: automatic cell sorting machine, drum production line body (upper power drum conveying and lower double speed chain reflux, front and rear lifting machine transporting tooling fixtures), laser pole cleaning machine, laser welding machine, manual operation station, PACK packaging and unloading gantry crane, packaging line including: sealing machine, strapping machine, weighing machine, etc.

General equipment configuration and standards:

I. OCV Test Sorter Specification

Equipment introduction: This equipment is mainly used for voltage internal resistance testing and sorting of square aluminum shell batteries, manual feeding, belt caching, scanning, OCV testing and grading of materials, and belt conveying caching.

|

Equipment model |

LITH-ZT23003-08-01A |

|

External dimensions |

LWH:4800*2400*2500(mm) |

|

Control mode |

Industrial computer+PLC |

|

Manual operation position height |

850mm±20mm |

|

Loading method |

Manual feeding |

|

Sports mechanism |

X. . Z servo motion |

|

OCV testing accuracy |

±0.01% rdg ±3 dgt |

|

Sorting efficiency |

8-12PPM |

|

Cell cache position |

8Channels (7 OK channels+1 NG channel) |

|

Number of gear cache cells |

10个 |

|

Cache gear width |

25-75(mm)adjustable |

|

OCV tester specifications |

BT3562A/BT3561A |

|

Cell conveying speed |

0.2-0.8 meters/second |

|

communication |

MES system/serial communication |

|

Equipment weight |

800KG |

|

Power |

5KW |

|

Power configuration |

AC220V、50HZ |

|

Security protection |

Emergency stop and alarm indicator lights |

II. Specification for pole laser cleaning machine

Equipment introduction: This equipment is used for cleaning the pole of square aluminum shell batteries. It adopts a three-axis gantry mechanical arm, a domestically produced high-quality laser, a laser rangefinder and CCD positioning, and a sensor for material sensing to achieve intelligent production.

|

Equipment model |

TMAX-ZT23003-08-02A |

|

External dimensions |

Dimensions(LWH):2500*1800*2500(mm) |

|

Control mode |

IPC+PLC |

|

Manual operation position height |

850mm±20mm |

|

Loading method |

Automatic feeding of drum line |

|

Sports mechanism |

X. Y.Z servo motion |

|

Visual system |

Inspection distance: 300mm, pixel: 300000, inspection method: COMS |

|

Cleaning efficiency |

120 seconds per unit (module or PACK package) |

|

Module/PACK positioning method |

Jacking positioning |

|

Positioning accuracy of motion mechanism |

±0.05mm |

|

Maximum device compatibility |

Length * Width=800*500mm |

|

Laser power |

100W |

|

Dust removal purifier power |

200W |

|

Maximum speed of motion mechanism |

0 .5m/s |

|

Communication |

MES system/serial communication |

|

Equipment weight |

700KG |

|

Power |

7KW |

|

Power configuration |

AC220V、50HZ |

|

Safety protection |

Emergency stop, alarm indicator light |

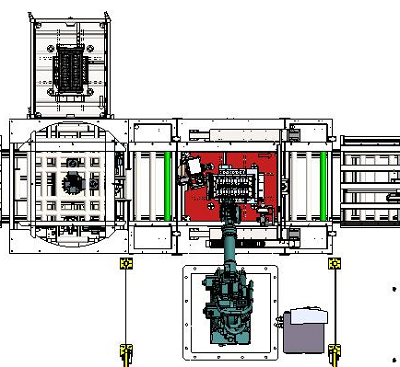

III. Specification for Robot Laser Welding Machine

Equipment introduction: This equipment is mainly used for welding square aluminum shell battery busbars. It uses Yaskawa robots, domestically produced high-quality lasers, laser rangefinders, and CCD positioning and addressing. It is equipped with a dust removal mechanism to effectively remove smoke and dust generated during welding, achieving intelligent production.

|

Equipment model |

TMAX-ZT23003-08-03A |

|

External dimensions |

Dimensions(LWH):4100*5200*3500(mm) |

|

Control mode |

Industrial computer+PLC |

|

Six axis robot |

MOTOMAN-GP180 |

|

Loading method |

Automatic feeding of drum line |

|

Sports mechanism |

X. Y.Z servo motion |

|

Visual system |

Inspection distance: 300mm, pixel: 300000, inspection method: COMS |

|

Welding efficiency |

120 seconds per unit (module or PACK package) |

|

Module/PACK positioning method |

Jacking positioning |

|

Positioning accuracy of motion mechanism |

±0.05mm |

|

Maximum device compatibility |

L*W=800*500mm |

|

Laser power |

6000W |

|

Dust removal purifier power |

800W |

|

Maximum speed of motion mechanism |

0 .5m/s |

|

Communication |

MES system/serial communication |

|

Equipment weight |

4000KG |

|

Power |

20KW |

|

Power configuration |

AC220V、50HZ |

|

Safety protection |

Emergency stop, alarm indicator light |

IV. ATE test specification sheet

|

Equipment model |

TMAX-ZT23-ATE |

|

External dimensions |

Dimensions(LWH):900*800*930(mm) |

|

Control mode |

Industrial computer+software |

|

Noise |

less than 70dB |

|

Operating environment humidity |

10%~95%(RH non condensing) |

|

Operating ambient temperature |

0℃~40℃(RH non condensing) |

|

MES system |

Support data upload to MES (interface documentation and upload project required) |

|

AC withstand voltage test |

Output voltage range: 0.1kV~5kV, current testing range:0.001mA~40mA Maximum rated load:200VA(5kV/40mA) |

|

Internal resistance test |

Output voltage range:50V~1000V,resistance measurement range: 1MΩ~9500MΩ Output Impedance:600kΩ |

|

Accuracy |

±0.1%FS |

|

Resolution ratio |

1mA/1mV |

|

Security level |

Complies with EN60950 and GB4943 requirements |

|

Lightning protection level |

Meet the 2-pole lightning protection requirements of GB17626 |

|

Protection grade |

IP20 |

|

Communication |

CAN communication protocol, compatible with 485 communication |

|

Equipment weight |

150kG |

|

Power |

40KW(full load) |

|

Power configuration |

AC380V/220、50HZ |

|

Safety protection |

Emergency stop, alarm indicator light |

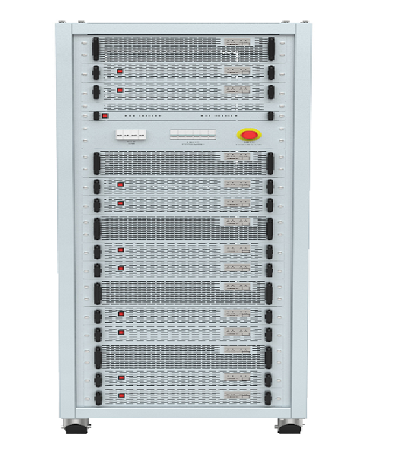

V. Aging Test Specification

Equipment Introduction: The BTS100-100-8CH system is a high-precision charging and discharging equipment designed and developed specifically for testing medium and low power battery packs. It is mainly used for battery pack capacity testing, shipment inspection, endurance testing, and product design verification. The system adopts a design architecture with recyclable energy, and the discharge energy of the battery pack is recycled and reused, achieving the effects of energy conservation, environmental protection, and low thermal energy output.

|

Equipment model |

TMAX-BTS100-100-8CH |

|

External dimensions |

600mm*800mm*1990mm |

|

Control mode |

Industrial computer+software |

|

Operating environment humidity |

10%~95%(RH non condensing) |

|

Operating ambient temperature |

0℃~40℃(RH non condensing) |

|

Channel working mode |

Charging: constant current charging, constant voltage charging, constant current constant voltage charging, constant power charging Discharge: constant current discharge, constant power discharge, standing, DCR test |

|

Channel voltage |

Channel voltage range: 0-100Vdc, discharge voltage range: 5Vdc~100Vdc Accuracy: ± (0.05% FS+0.05% RD) |

|

Channel current |

Current output range: ± 200A, discharge current range: 0.6A~200A Accuracy: ± 0.1% FS |

|

Stability |

±0.1%FSR |

|

Resolution ratio |

1mA/1mV |

|

Security level |

Complies with EN60950 and GB4943 requirements |

|

Lightning protection level |

Meet the 2-pole lightning protection requirements of GB17626 |

|

Protection grade |

IP20 |

|

Communication |

CAN communication protocol, compatible with 485 communication |

|

Power |

160KW (full load) |

|

Power configuration |

AC380V/220V、50HZ |

|

Safety protection |

Power failure data protection, overvoltage and over discharge protection, overcurrent protection, capacity protection, over temperature protection, open circuit protection, short circuit protection, battery reverse connection, and wrong connection protection |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588