ItemNo :

LITH-SS300MOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com300-Type Automatic Stacking Machine for Lithium Battery Electrode Assembly

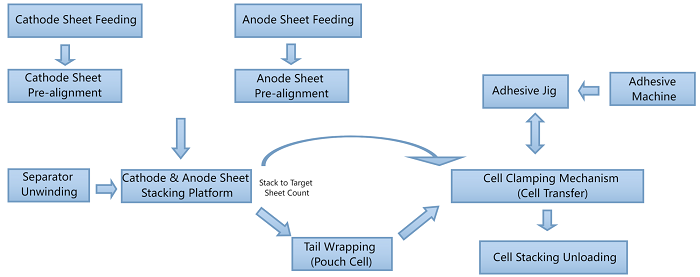

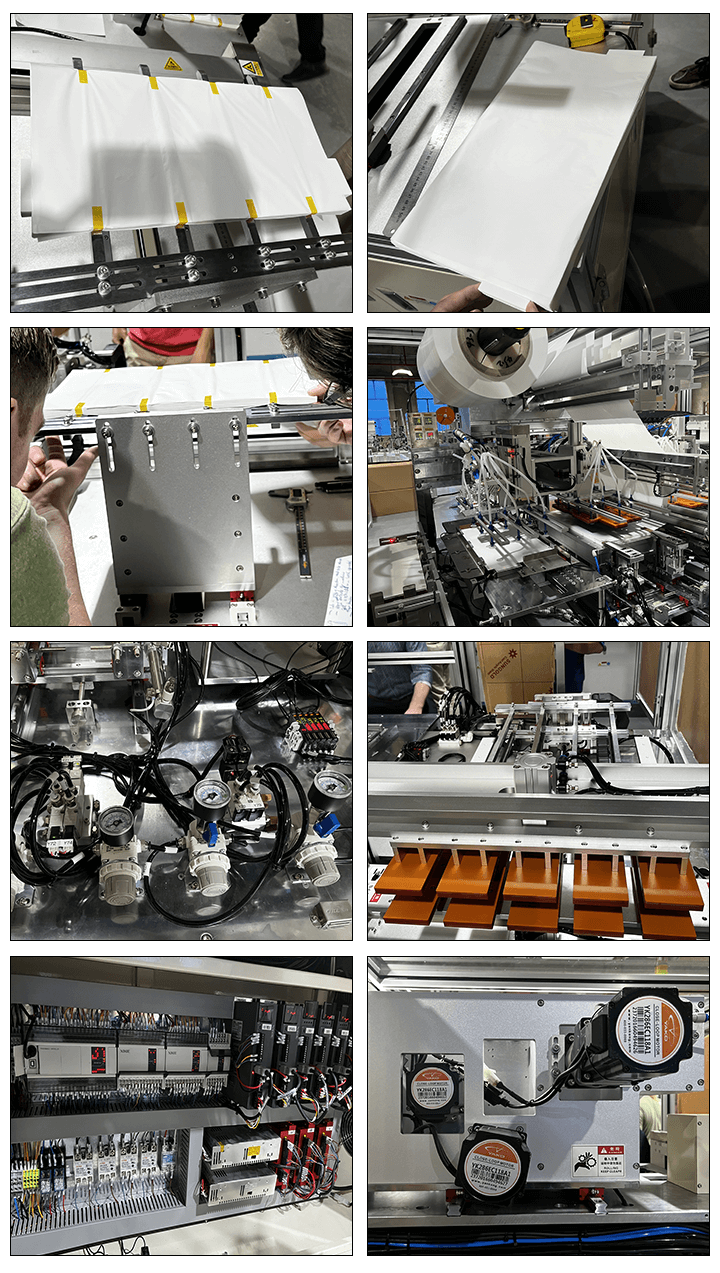

This equipment is used for Z-fold stacking of lithium-ion battery cells, including positive and negative electrodes and separators. It adopts a single-station stacking method. The separator is actively unwound and guided through a tension mechanism to the stacking platform, which moves the separator back and forth to allow placement of the electrode sheets. The positive and negative electrodes are picked up by two sets of robotic arms from the respective left-side material hoppers, then precisely positioned and stacked onto the platform. After reaching the preset number of layers, the tail is automatically wrapped (switchable to tail-free mode). The cell is then clamped, the separator is cut, and the clamped cell is transferred to the taping station for automatic taping. Meanwhile, the separator is blown and flipped to start the next stacking cycle. The taped cell is stacked and unloaded.

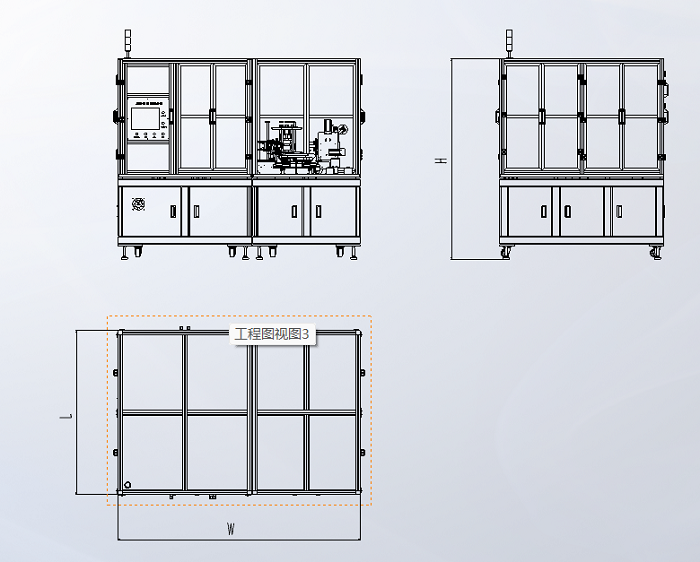

Overall dimensions: W2600mm × L1800mm × H2200mm (final dimensions subject to design)

|

Material |

Form |

Length (mm) |

Width (mm) |

Thickness (µm) |

Inner Ø (mm) |

Max Outer Ø (mm) |

|

Positive Electrode |

Sheet |

130–260 |

130–260 |

100–250 |

— |

— |

|

Negative Electrode |

Sheet |

130–260 |

130–260 |

80–150 |

— |

— |

|

Positive Tab |

— |

10–30 |

10–50 |

10–25 |

— |

— |

|

Negative Tab |

— |

10–30 |

10–50 |

6–15 |

— |

— |

|

Separator |

Roll |

— |

100–280 |

12–45 |

Φ76.2 |

Φ300 |

|

Tape |

Roll |

— |

8 |

20–50 |

Φ76.2 |

Φ150 |

Notes:

1. Electrode length refers to the tab direction excluding tab length.

2. No significant powder loss or edge waviness; burrs ≤15 µm; die-cutting error <0.2 mm.

3. No significant warping, sticking, or deformation of electrodes.

4. Separator snake-like deviation: ±0.2 mm/1000 mm.

|

Item |

Specification (mm) |

Cell Diagram |

|

Cell Length (L) |

130–260 |

|

|

Cell Width (W) |

130–260 |

|

|

Cell Thickness (T) |

10–90 |

|

|

Tab Length (L1) |

10–30 |

|

|

Tab Orientation |

Same-side / Opposite-side |

|

|

If opposite-side, L + L1 ≤ |

260 |

|

Item |

Value |

|

Stacking Time per Sheet |

1.3–1.5 s/pcs |

|

Auxiliary Time per Cell |

≤10 s |

|

Electrode-Separator Alignment |

±0.3 mm center deviation |

|

Separator Edge Alignment |

±0.3 mm |

|

Adjacent Electrode Alignment |

±0.2 mm |

|

Overall Electrode Alignment |

±0.3 mm |

|

Number of Stacking Layers |

Adjustable within thickness range |

|

Outer Wrap |

Tail wrapping |

|

Availability Rate |

95% (machine-caused only) |

|

Pass Rate |

98% (machine-caused only) |

1. Equipment Module Composition

|

No. |

Module Name |

Qty |

Description |

|

1 |

Frame Module |

2 |

Structural support and installation base |

|

2 |

Material Hopper Module |

2 |

Stores electrodes, lifts to set height, with anti-multiple-sheet and dust-removal functions |

|

3 |

Secondary Positioning |

2 |

Precise electrode positioning on the platform |

|

4 |

Robotic Arm Module |

2 |

Transfers electrodes from hoppers to platform |

|

5 |

Separator Unwinding Module |

1 |

Motor-driven unwinding with automatic alignment |

|

6 |

Stacking Platform |

1 |

Z-fold stacking of positive, negative electrodes, and separator |

|

7 |

Separator Cutting Module |

1 |

Hot-wire cutting for separator |

|

8 |

Cell Clamping Module |

1 |

Transfers cells from platform to taping station |

|

9 |

Taping Module |

1 |

Side taping of cell; adjustable tape quantity |

|

10 |

Cell Unloading Module |

1 |

Stacks and unloads taped cells |

|

11 |

Protective Cover |

2 |

Sealed enclosure with access control |

|

12 |

Control System |

1 |

PLC control with touchscreen and button operation |

|

13 |

Vacuum System |

1 |

Vacuum generator / factory vacuum supply |

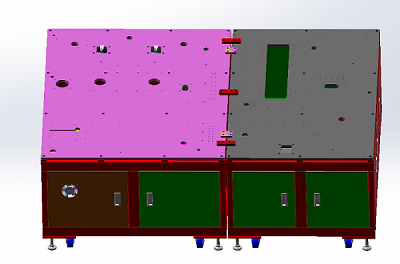

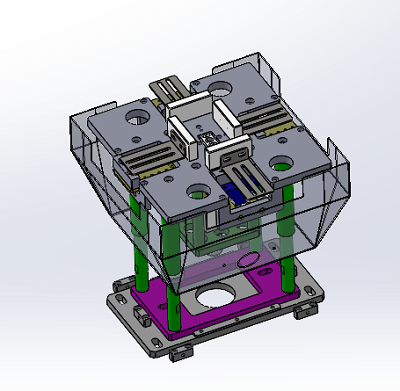

Function: Provides a unified installation surface and reference base for all moving parts.

Configuration:

|

No. |

Item |

Description |

|

1 |

Frame |

Constructed from high-strength square steel tubes with milled mounting surfaces and a painted finish. |

|

2 |

Base Plate |

Made from carbon steel, surface ground and chrome-plated. |

Function: Stores electrode sheets and lifts them to a fixed height for robotic pickup; includes anti-multiple sheet and dust removal features.

Configuration:

|

No. |

Item |

Description |

|

1 |

Lifting Device |

Through-beam photoelectric sensor detects stack height, lifting mechanism raises sheets to a set height for reliable pickup. |

|

2 |

Material Detection |

Photoelectric sensor triggers alarm and stops the machine when material runs out. |

|

3 |

Isolation Design |

Separation between positive and negative hoppers to avoid cross-contamination. |

|

4 |

Anti-Multiple Sheet |

Airflow disperses upper sheets; brush separator prevents misfeeding or sheet fallout. |

|

5 |

Dust Removal |

Suction box on hopper side connects to vacuum system. |

Function: Positions electrode sheets with cylinder-driven push plates; includes multi-sheet detection.

Configuration:

|

No. |

Item |

Description |

|

1 |

Positioning |

Electrodes placed on platform; cylinders align all four sides. |

|

2 |

Multi-sheet Detection |

Ultrasonic sensor detects sheet presence and multiple layers. |

|

3 |

Dust Removal |

Dust collection box with vacuum system removes particles from the platform. |

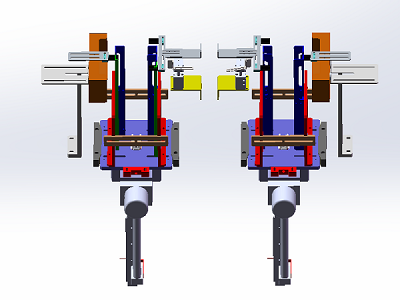

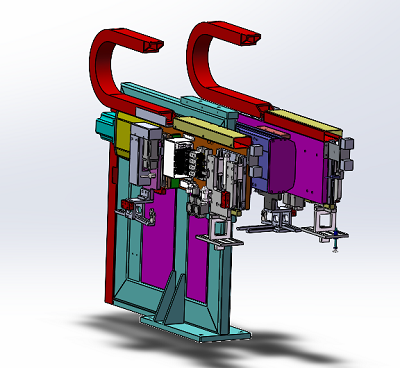

Function: Transfers electrode sheets from hopper to positioning platform and stacking table.

Configuration:

|

No. |

Item |

Description |

|

1 |

Drive |

Servo motor drives linear module with dust cover; high-speed and precision with ±0.02 mm accuracy. |

|

2 |

Rear Pickup |

Servo-driven lift with vacuum pad, vacuum detection, and dust filtration; includes sheet-shaking function. |

|

3 |

Front Pickup |

Cylinder-driven lift with integrated vacuum suction board and vacuum detection. |

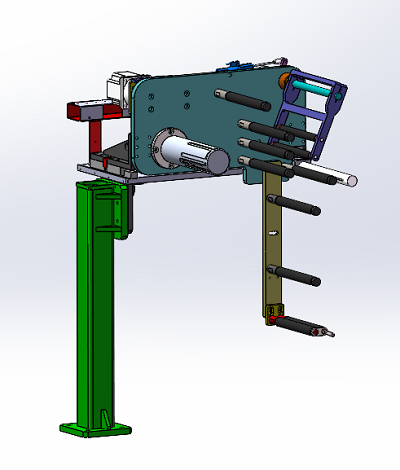

Function: Motor-driven separator unwinding, tension control, alignment correction, and anti-static features.

Configuration:

|

No. |

Item |

Description |

|

1 |

Loading |

Pneumatic shaft with scale marking for easy and accurate roll loading. |

|

2 |

Unwinding |

Motor unwinds separator with tension arms and regulated air pressure. |

|

3 |

Alignment |

Servo motor corrects roll alignment with ±15 mm stroke and ≤±0.15 mm accuracy. |

|

4 |

Anti-static |

Prevents dust adhesion to separator. |

|

5 |

Guide Rollers |

Made of aluminum alloy with mirror finish. |

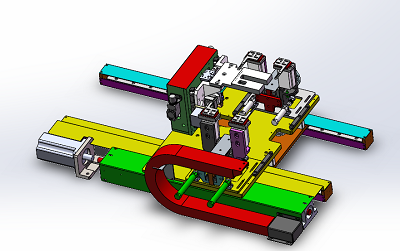

Function: Moves left and right to stack electrodes and separator into a cell.

Configuration:

|

No. |

Item |

Description |

|

1 |

Drive |

Servo motor drives lead screw for lateral movement with ≤±0.02 mm accuracy. |

|

2 |

Elevation |

Motor-driven platform descends with stacking; configurable drop height per sheet. |

|

3 |

Press Blade |

Cylinder-driven blade with adjustable pressure; uses polished special material to prevent scratches. |

|

4 |

Vacuum Adsorption |

Vacuum ports hold the first separator layer to prevent shifting. |

|

5 |

First Layer Alignment |

Motor-driven suction plate aligns tail end of separator; precision ≤0.3 mm. |

Function: Uses heated wire to cut the separator.

Configuration:

|

No. |

Item |

Description |

|

1 |

Drive |

Cylinder moves the cutter into position. |

|

2 |

Cutting |

Heated wire suitable for both standard and ceramic separators; no sintering or stringing defects. |

|

3 |

Precision |

Cutter trims separator flush with platform, with ≤2 mm excess. |

Function: Pneumatic gripper transfers the cell to the taping module.

Configuration:

|

No. |

Item |

Description |

|

1 |

Drive |

Servo motor drives timing belt; gripper rotates to access stacking and taping positions. |

|

2 |

Clamping |

Pneumatic gripper with adjustable pressure. |

|

3 |

Gripper Pads |

Foam-padded to protect cells; air jets lift separator edges to prevent folding. |

Function: Applies side taping based on taping process; tape quantity adjustable.

Configuration:

|

No. |

Item |

Description |

|

1 |

Taping Fixture |

Cylinder clamps cell; fixtures allow 4-side taping with cutouts for tape. |

|

2 |

C-Type Taping |

Automated unwind, feed, and cut; Teflon-coated rollers and motors simulate C-path taping. |

|

3 |

Operation |

Local control buttons for manual adjustment. |

|

4 |

Tape Quality |

No wrinkles; does not damage tabs, electrodes, or separator; cut length tolerance ≤1 mm; tape position accuracy ±0.5 mm. |

Function: Stacks and unloads finished cells.

Configuration:

|

No. |

Item |

Description |

|

1 |

Discharge Gripper |

Pneumatic clamp transfers cells from buffer to unloading station. |

|

2 |

Platform |

Elevator-type platform holds 5–10 cells. |

Function: Provides a semi-sealed environment with interlock safety.

Configuration:

|

No. |

Item |

Description |

|

1 |

Safety |

Aluminum and acrylic enclosure with door interlocks; prevents operation when open. |

Function: PLC-based system with touchscreen and button interface.

Configuration:

|

No. |

Item |

Description |

|

1 |

Operating Principle |

Uses PLC for reliable control, simple wiring, interference resistance, and easy maintenance; fast response and scan cycle enhances efficiency. |

|

No. |

Item |

Brand |

Remarks |

|

1 |

Cylinder |

AIRTAC |

|

|

2 |

Linear Guide |

DINGHAN/HIWIN |

|

|

3 |

Ball Screw |

TBI/HIWIN |

|

|

4 |

PLC |

OMRON |

|

|

5 |

Touch Screen |

Kunlun Tongtai |

|

|

No. |

Component |

Part |

Unit |

Quantity |

Remarks |

|

1 |

Electrode Hopper |

Hopper Base Plate |

pcs |

2 |

Adjustable within a certain range |

|

2 |

Pre-positioning |

Adjustment Plate |

pcs |

2 |

|

|

3 |

Stacking Robot |

Press Plate |

pcs |

2 |

|

|

4 |

Stacking Table |

Stacking Plate |

pcs |

4 |

|

|

5 |

Alignment Suction Plate |

pcs |

1 |

||

|

6 |

Discharge Module |

Discharge Support Plate |

pcs |

2 |

|

|

7 |

Taping Module |

Taping Fixture |

set |

1 |

|

|

8 |

Other |

- |

- |

- |

|

|

No. |

Item |

Model/Spec |

Manufacturer |

Remarks |

|

1 |

Suction Nozzle |

Custom |

Machined Part |

Needs daily cleaning |

|

4 |

Vacuum Filter |

VFD-3-06 |

CHELIC |

Clean weekly |

|

5 |

Vacuum Generator |

VAB-0706 |

CHELIC |

Clean weekly |

|

6 |

Foam |

- |

Auxiliary |

Attached to contact surface with cells |

|

7 |

Teflon |

- |

Auxiliary |

Attached to contact surface with electrodes |

|

No. |

Item |

Specification |

Quantity |

Manufacturer |

Remarks |

|

1 |

Allen Wrench Set |

M1.5–M10 |

1 set |

Shanghai Tools |

|

|

2 |

Open Wrench Set |

M5.5–M22 |

1 set |

Shanghai Tools |

|

|

3 |

Needle Nose Pliers |

6-inch |

1 |

Shanghai Tools |

|

|

4 |

Adjustable Wrench |

6-inch |

1 |

Shanghai Tools |

|

|

5 |

Toolbox |

160×330 |

1 |

Songmei |

|

|

No. |

Item |

Quantity |

Unit |

Remarks |

|

1 |

Delivery Specification |

1 |

set |

Provided post-signing, one returnable copy |

|

2 |

Quality Inspection Report |

1 |

set |

Provided at delivery |

|

3 |

User Manual |

1 |

set |

Provided at delivery |

|

4 |

Spare Parts (with List) |

1 |

set |

Provided at delivery |

|

5 |

Changeover Parts (with List) |

1 |

set |

Provided at delivery |

|

6 |

Wear Parts List |

1 |

set |

Includes model numbers and drawings |

|

7 |

Wiring Diagram |

1 |

set |

Provided after acceptance and 90% payment |

|

8 |

Delivery Note |

1 |

set |

|

|

Item |

Specification |

|

Weight/Load |

Approx. 2500 kg; >650 kg/m² (subject to final design) |

|

Color |

Computer White (color samples required if custom) |

|

Power Supply |

AC220V, 3-phase; voltage fluctuation ±10%; 60Hz |

|

Compressed Air |

0.5–0.7 MPa (5–7 kgf/cm²), usage: 200 L/min |

|

Vacuum |

Vacuum generator or plant-supplied vacuum source |

|

Ambient Temp. |

5–35°C |

|

Relative Humidity |

5–55% RH |

|

Air/Dust |

No corrosive, toxic, or conductive dust or gas |

|

Magnetic Field/Vibration |

No interfering magnetic fields or shocks |

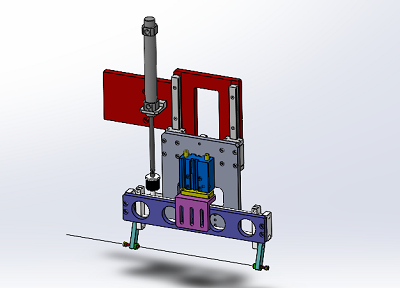

![]()

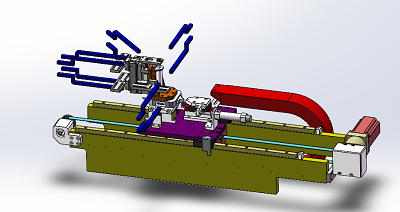

![]()

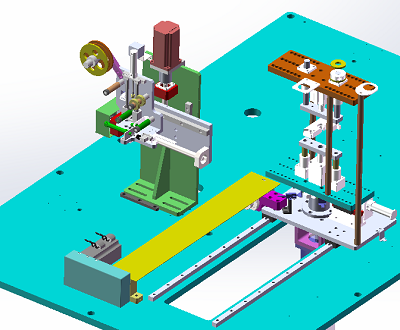

![]()

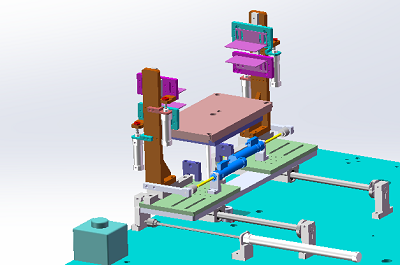

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975