- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-LFH-200MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

Product Introduction:

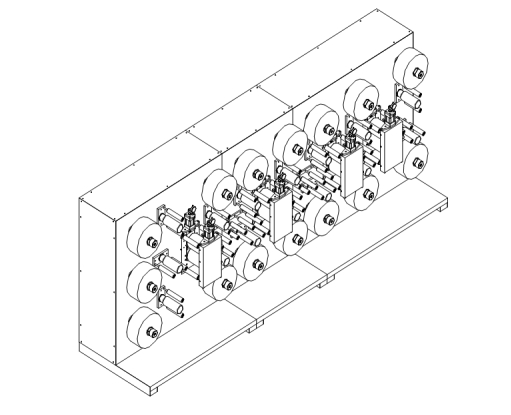

The LITH-LFH-200 lithium and copper foil rolling composite machine is designed specifically for solid-state battery anode production.

Technical Specifications:

1. Masterbatch (PP film coated) Incoming Size:

- Lithium Strips:

- Width: ≤ 200mm

- Thickness: 30μm ≤ thickness ≤ 50μm

- Rolled Material Outer Diameter: ≥ ¢ 350mm

- Weight: > 8kg

- Copper Film:

- Width: ≤ 240mm

- Thickness: (6 ~ 10) μm

- Copper Roll Material Outer Diameter: ≤ ¢ 300 mm

- Weight After Winding: ≥ 20kg

2. Laminating Function:

- Capable of single and double-sided laminating with copper foil.

- Product surface is free of wrinkles and defects after laminating lithium strips and copper foil.

- Alignment of front and back or single side edges of lithium strips and copper foil after lamination: <±1mm.

- Ductility in width direction: ≈5.0-6.0%.

3. Double-Sided Copper Foil Wrapping:

- PP film used as a protective layer between each layer.

- Winding length: >1000m.

Equipment Technical Parameters:

|

Item |

Details |

|

Equipment capacity |

Design speed ≥ 25m/min, acceptance speed ≥ 10m/min (lithium tape must be ≥ 8m/min when overlaid onto copper tape) |

|

Equipment failure rate |

≤5.0% |

|

Product first-time optimization rate |

≥ 98% (only the equipment itself causes damage) |

|

Power supply |

380V three-phase five wire system |

|

Energy consumption |

15KW |

|

Equipment appearance color |

The specific appearance color shall be based on the color palette provided by the buyer |

|

Noise |

≤75dB (measured at 1000mm from the outer wall of the equipment) |

|

Load-bearing ratio |

≤ 500Kg/m2 (under full operating conditions of the equipment) |

|

Equipment usage environment |

23 ± 3 ℃, RH ≤ 1% or dew point: ≤ -45 ℃ or above |

|

Incoming Material Handling |

Lithium strip coated with PP film. Stripping and flattening roller device ensures lithium strip separation from PP film before lamination. Separated PP film is individually wound by the winding mechanism. |

|

Production Speed |

3m/min ≤ V ≤ 30m/min. |

|

Laminating Machine Design |

Independent PP film unwinding mechanism for double-sided lithium coating on copper foil strips. PP film used as a protective layer between each layer during lamination. |

|

Automatic Control System |

Complete system for winding tension control. Ensures product is not stretched during winding. |

|

Unwinding Mechanisms |

Active unwinding mechanism and automatic deviation correction system. Deviation correction accuracy: ± 0.2mm. |

|

Static Electricity Removal |

Release film PET (PP) winding and unwinding mechanism equipped with static electricity removal device. |

|

Product Winding Mechanism |

Meets winding requirements of 3-inch core (outer diameter 350mm) and inner hole ¢20 reel. |

|

Pressure Specifications |

Maximum pressure of lithium copper cladding: 10T (single side 5T). Servo automatic adjustment with digital display of clearance and pressure. |

|

Laminating Roller |

Capable of switching between differential and same speed. Cumulative error after installation: ≤ 3μm. Surface smoothness without defects; roller body hardness: >HRC65; surface coating hardness: >HRC75. |

|

Copper Foil Corona Generator |

Equipped to meet process requirements for copper foil surface treatment. |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588