- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-LKZY-6MOQ :

1Delivery Time:

5 days

Semi-Automatic Prismatic Cell Electrolyte Filling System with Rotary Function

|

Equipment Name |

Applicable Product |

Remarks |

|

Rotary automatic electrolyte filling machine |

Prismatic cells |

1-out-6 differential-pressure filling; pre-/post-filling scanning & weighing, MES data interface |

2.1 This equipment adopts differential-pressure filling for prismatic cells.

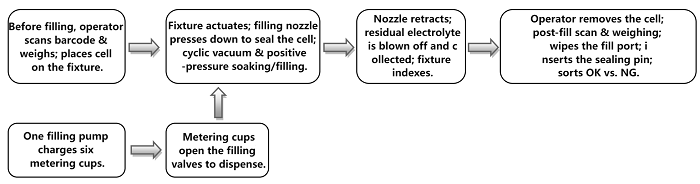

2.2 Process steps: manual barcode/QR scanning and weighing, manual place/remove cells to/from fixtures, automatic filling, differential-pressure hold (vacuum/pressurization), manual wipe residual electrolyte at the fill port and insert the sealing plug.

2.3 Installed inside a dry room. The operator side is open and protected by a safety light curtain; the other three sides use movable doors/windows.

2.4 Scan/weight data are stored in an industrial PC; the database is separate from the PLC. Post-scan/weight data are documented and viewable on the IPC monitor. The machine provides TCP/IP or RS-232 interfaces for data communication/networking and future expansion (ports reserved). Data can be exported via USB or uploaded to the MES.

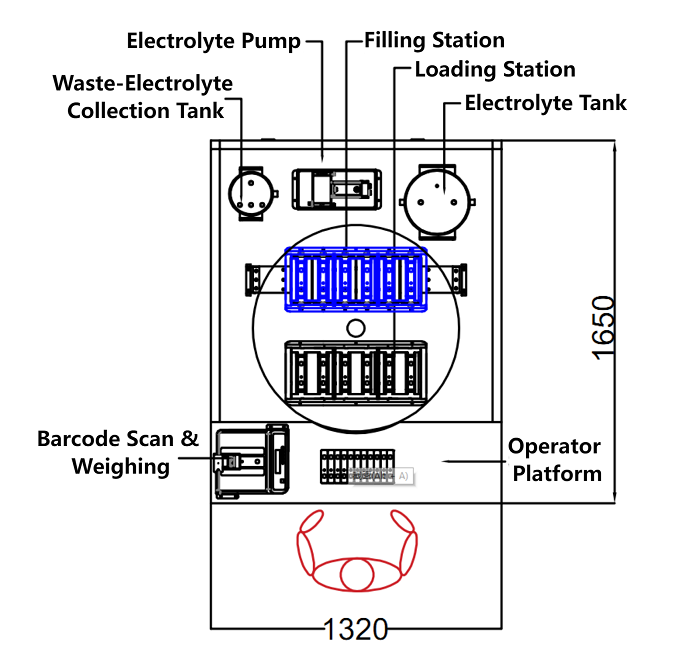

2.5 Process schematic:

2.6 Overall dimensions: 1320 mm (L) × 1650 mm (W) × 2400 mm (H).

2.7 Action flow:

2.8 Cell specification requirements:

|

Item |

Parameter (mm) |

Cell spec |

|

Cell height (H), excl. terminals |

130 |

|

|

Cell width (L) |

185 |

|

|

Cell thickness (W) |

36 |

|

|

Fill-port location range (D2) (consistent within same model) |

20–40 |

|

|

Fill-port diameter (D1) |

2.0–4.0 |

|

|

Fill quantity |

100–300 g |

One set of baseline cell fixtures is supplied. Baseline cell model 36130200, compatible with 40160185.

3.1 Power: AC 220 V / 50 Hz, power ≤ 3.0 kW

3.2 Compressed air: ≥ 0.6 MPa; consumption ≤ 800 L/h

3.3 Vacuum source: ≤ −0.090 MPa; vacuum gas consumption ≤ 2000 L/h

3.4 Nitrogen: 0.2–0.6 MPa; consumption ≤ 2000 L/h

3.5 Ambient dew point: ≤ −40 °C Td (dew-point meter by buyer)

|

No. |

Item |

Technical Parameter |

Remarks |

|

1 |

Throughput |

≥ 1.2 PPM |

Filling + vacuum/pressurization hold ≤ 280 s |

|

2 |

Filling pressurization/hold time |

≤ 280 s |

|

|

3 |

Pump accuracy |

±5‰ |

|

|

4 |

Fill-volume setting |

Touchscreen |

|

|

5 |

Max single-stroke pump range |

≈ 50 g |

Over-range can be split into multiple strokes |

|

6 |

Pump spec/qty |

Single-head piston metering pump, 1 set |

Optional model |

|

7 |

Machine filling accuracy |

±1% |

|

|

8 |

Filling method |

Differential-pressure filling |

Alternating vacuum/positive pressure inside cell |

|

9 |

Filling process |

Primary & secondary filling |

Max 200 g per single fill |

|

10 |

Dosing to cups |

1 pump → 6 cells sequentially |

|

|

11 |

Filling vacuum |

−80 ~ −90 kPa |

Vacuum source by buyer |

|

12 |

Filling positive pressure |

0.2–0.5 MPa |

Nitrogen source by buyer |

|

13 |

Filling mode |

Quantitative (metered) filling |

|

|

14 |

Gas supply assurance |

Machine equipped with vacuum tank and pressure tank |

|

|

15 |

Cell positions |

1-out-6, up to 6 cells simultaneously |

|

|

16 |

Filling control mode |

Independent control; tail-end cell count selectable on HMI |

|

|

17 |

Seepage/leakage protection |

During alternating vacuum/positive-pressure wetting, if pressure does not reach setpoints, the machine shuts off the corresponding cell channel, alarms, and flags NG for rejection. |

|

|

18 |

Baseline cell model |

36130200 |

Compatible with 40160185 |

|

19 |

Cell fill-port diameter |

Ø2–Ø4 mm |

Buyer to ensure incoming consistency |

|

20 |

Needle-to-cell seal |

EPDM O-ring compressed seal |

|

|

21 |

Fixture tray type |

Dedicated fixture |

|

|

22 |

Tray fixation |

Fixed to fixture baseplate |

|

|

23 |

Metering-cup capacity |

≤ 400 g, stainless steel |

|

|

24 |

Electrolyte feeding |

Automatic refilling |

|

|

25 |

Electrolyte tanks |

2 tanks (1 for degassing/standing, 1 for filling) |

|

|

26 |

Tank volume |

≥ 5 L each |

|

|

27 |

Waste-electrolyte collection |

1 dedicated stainless collection tank |

|

|

28 |

Electronic balance range |

6 kg (with signal-output feedback) |

|

|

29 |

Electronic balance accuracy |

0.1 g (with signal-output feedback) |

|

|

30 |

Balance quantity |

1 set |

Shared pre/post filling |

|

31 |

Scanner response time |

≤ 3 s |

Optional model |

|

32 |

Scanner types |

Barcode or QR code, switchable via setup |

|

|

33 |

Scanner quantity |

1 set |

Shared pre/post |

|

34 |

Barcode location requirement |

Top of cell, upper face |

|

|

35 |

Scan/weight data handling |

Industrial PC |

Brand: Advantech |

|

36 |

Scan/weight MES interface |

Reserved MES interface, see separate doc |

|

|

37 |

Local data viewing |

Monitor |

|

|

38 |

NG handling |

Software alarm, manual sorting/rejection |

|

|

39 |

Scanning & weighing |

Manual |

|

|

40 |

Cell loading |

Manual |

|

|

41 |

Cell unloading |

Manual |

|

|

42 |

Plug removal/insertion |

Manual |

|

|

43 |

Fill-port wiping |

Manual |

|

|

44 |

Residual-electrolyte handling |

Blow-off residual collection mechanism |

|

|

45 |

Safety protection |

Safety light curtain on operator side |

|

|

46 |

Corrosion resistance |

All wetted fittings/tubing are corrosion-resistant; internal screws stainless steel |

|

|

47 |

Start protection |

Foot switch |

|

|

48 |

Machine weight |

≤ 1800 kg |

|

|

49 |

Color/finish |

Warm gray 1C baked paint |

|

|

50 |

First-pass yield |

≥ 99.5% |

|

|

51 |

Machine failure rate |

≤ 2% |

|

|

52 |

Max cell deformation |

≤ 0.8 mm (one side) |

|

|

53 |

Equipment utilization |

≥ 95% |

|

I. Upper/Lower Enclosure

1. Upper/lower frames: square-tube, baked paint; door/window sheet-metal painted; view windows use PC transparent panels.

2. Infeed/outfeed isolate the interior from the exterior.

3. For use in a dry room; door/window sealing is not applied.

4. Foot-switch start at the console; light curtain at loading position.

5. Equipped with one vacuum tank and one pressure tank.

II. Rotary Fixture Mechanism

1. Two-station rotary table driven by motor + indexer; while one station is in filling/holding, the other allows manual load/unload without interference.

2. Fixture cavity is common; baffles are model-specific and must be replaced when changing cell models.

3. Operator loads/unloads cells into the fixture baffle.

III. Scanning & Weighing

1. One scanner and one electronic balance, shared pre/post filling.

2. Scan/weight data are bound to the IPC for automatic recording and analysis.

3. NG in scan/weight triggers software alarm; manual sorting.

IV. Electrolyte Supply System

1. Two electrolyte tanks: one for degassing/standing, one for filling; ≥ 5 L each.

2. Automatic refilling and automatic degassing functions.

V. Positive-Pressure System

3. External compressed air and nitrogen supplied by buyer.

4. Machine pressure tank stabilizes positive pressure.

5. 1-out-6 manifold, series-controlled lines.

VI. Vacuum System

1. External vacuum source supplied by buyer.

2. Machine vacuum tank stabilizes negative pressure.

3. 1-out-6 manifold, series-controlled lines.

VII. Filling Mechanism

1. Fill volume set on touchscreen; pump is a metering pump.

2. Six filling channels; up to 6 cells can be filled simultaneously.

3. Independent setpoints for vacuum and positive pressure; if actual values fall below/above setpoints, system automatically alternates vacuum/pressurize cycles.

4. Metering cups store electrolyte; nozzle seals to the cell fill port.

5. Differential-pressure filling with vacuum + positive-pressure operation.

6. Equipped with one intelligent piston pump that doses to six metering cups in sequence.

7. Vacuuming, pressurizing, venting, and liquid transfer are controlled by dedicated valves.

8. All wetted parts are corrosion-resistant materials.

9. Nozzle downforce adjustable; process requires ≥ 10 kgf per cell.

VIII. PLC Control System

1. PLC program controls the machine; parameters are set via touchscreen.

2. Functions include statistics & display of all alarms/faults, I/O and process states, other control/process/diagnostic information, real-time process data, throughput & FPY statistics, material info, and run/stop time.

|

No. |

Name |

Brand/Origin |

No. |

Name |

Brand/Origin |

|

1 |

PLC controller |

OMRON |

10 |

HMI (touch panel) |

Weinview/BoKe |

|

2 |

Cylinders |

AIRTAC |

11 |

Barcode scanner |

Domestic |

|

3 |

Filling pump |

Domestic |

12 |

Shutoff valve |

Iidaseiko / Domestic |

|

4 |

Electronic balance |

Domestic |

13 |

Lead screw & linear guide |

Domestic |

|

5 |

Indexer |

Domestic |

14 |

AC motor |

Domestic |

|

6 |

Servo motor |

Domestic |

15 |

Vacuum gauge |

SMC / AIRTAC |

|

7 |

Solenoid valve |

AIRTAC / Domestic |

16 |

Industrial PC |

Advantech |

|

8 |

Sensors |

OMRON / Domestic |

17 |

Vacuum valve |

AIRTAC / In-house |

|

9 |

Electrical control parts |

Domestic / CHINT |

18 |

Magnetic switch |

AIRTAC / Domestic |

VII. Reference Drawings

(Subject to the actual machine.)

|

No. |

Consumable |

Spec/Model |

Qty |

Remarks |

|

1 |

Nozzle sealing O-ring (EPDM) |

Non-standard, custom |

10 pcs |

With machine |

|

2 |

Waste-liquid seal (EPDM) |

Non-standard, custom |

2 pcs |

With machine |

|

3 |

Pump sealing O-ring (EPDM) |

Non-standard, custom |

2 pcs |

With machine |

|

4 |

Metering-cup seal (EPDM) |

Non-standard, custom |

6 pcs |

With machine |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588