- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-BRK-220MOQ :

1Warranty:

2yearsDelivery Time:

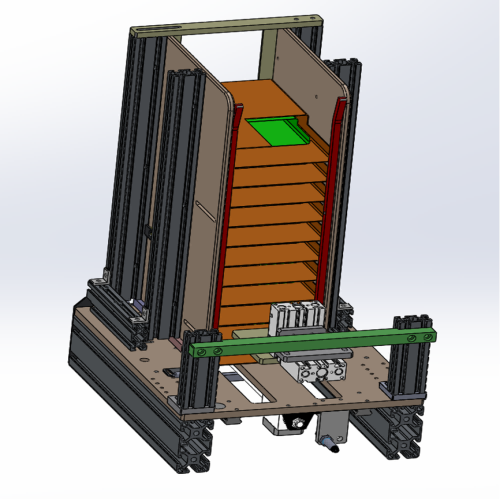

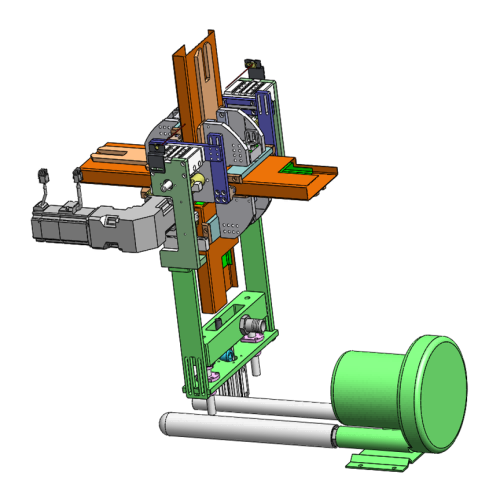

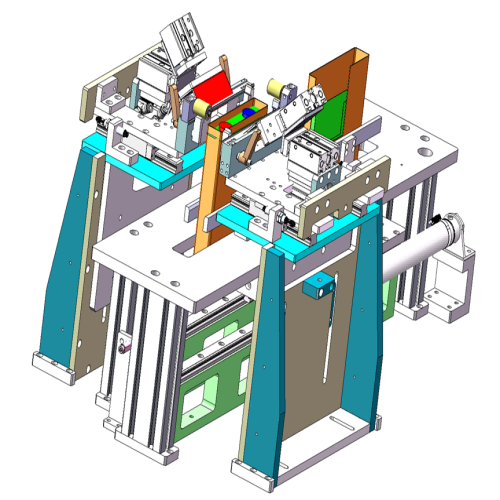

5 daysSemi-Automatic Prismatic Batetry Shell Feeder for Lab Production

1、 Device Functions

Equipment function: By manually installing the battery cell and battery casing, the casing and battery cell are first dust removed in the dust removal mechanism, and then transported to the shell feeding station. The mechanism achieves semi-automatic shell entry between the battery cell and the casing.

Overview of workflow:

Manually place the aluminum shell into the clamp - manually place the battery cell into the mechanism - position the shell after dust removal - automatically push the aluminum shell - automatically unloading the material.

2、 Technical parameters

|

Applicable cell size |

Prismatic cell size L * W * H (220mm * 135mm * 30mm) |

|

Dust removal time |

adjustable from 1.0 to 5.0 seconds. |

|

Number of aluminum shell buffers |

≥ 4PCS |

|

Reserved size for shell insertion |

3-5mm |

|

Equipment efficiency |

2PPM |

|

Utilization rate |

95% |

|

Pass rate |

99.5% |

3、 Main component configuration

1. Shell placement mechanism

2. Aluminum shell positioning dust removal mechanism

3. Shell feeding mechanism

4、 Component brand

1. Main device configuration

|

No. |

Name |

Brand |

|

1 |

servo motor |

Xinjie/Huichuan/Mitsubishi/Panasonic/Equivalent brands |

|

2 |

touch screen |

Weilentong/Xinjie/equivalent brand |

|

3 |

PLC |

Mitsubishi/Xinjie/Panasonic/Equivalent brands |

|

4 |

High pressure fan |

Rain Field/Equivalent Brand |

|

5 |

cylinder |

SMC/ADK/Equivalent brand |

|

6 |

Solenoid valve |

SMC/ADK/Equivalent brand |

|

7 |

Screw guide rail |

HIWIN/KKT/Equivalent brand |

|

8 |

Induction switch |

Omron/Keyence/equivalent brand |

5、 Installation environment requirements

1. Configuration power supply: AC380V, 50Hz, voltage fluctuation range:+10%~-10%;

2. Total power of the equipment: approximately 2KW;

3. Compressed air: 0.25~0.8Mpa; Pressure fluctuation ± 1%

4. Equipment specifications:

1) Equipment weight: approximately 1 ton;

2) Overall dimensions: approximately 2100x1320x1970mm (length x width x height);

3) Appearance color: light gray or customer specified.

5. Environmental requirements:

1) Environmental temperature: 25 ± 5 ℃;

2) Relative humidity: 30% to 75% RCH, ensuring that the on-site air is dry and unobstructed, without acid or alkali corrosion;

3) Ground wire: protective grounding.

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588